In the digital printing industry, equipment complexity continues to increase, and after-sales services face challenges such as difficult fault diagnosis, high repair costs, and slow improvement in customer satisfaction. The in-depth application of 3D animation technology is reshaping the after-sales service system for digital printing machines, achieving a fundamental transformation from passive response to proactive service, and from a cost center to value creation.

Precise Reproduction: From Abstract Description to Visual Diagnosis

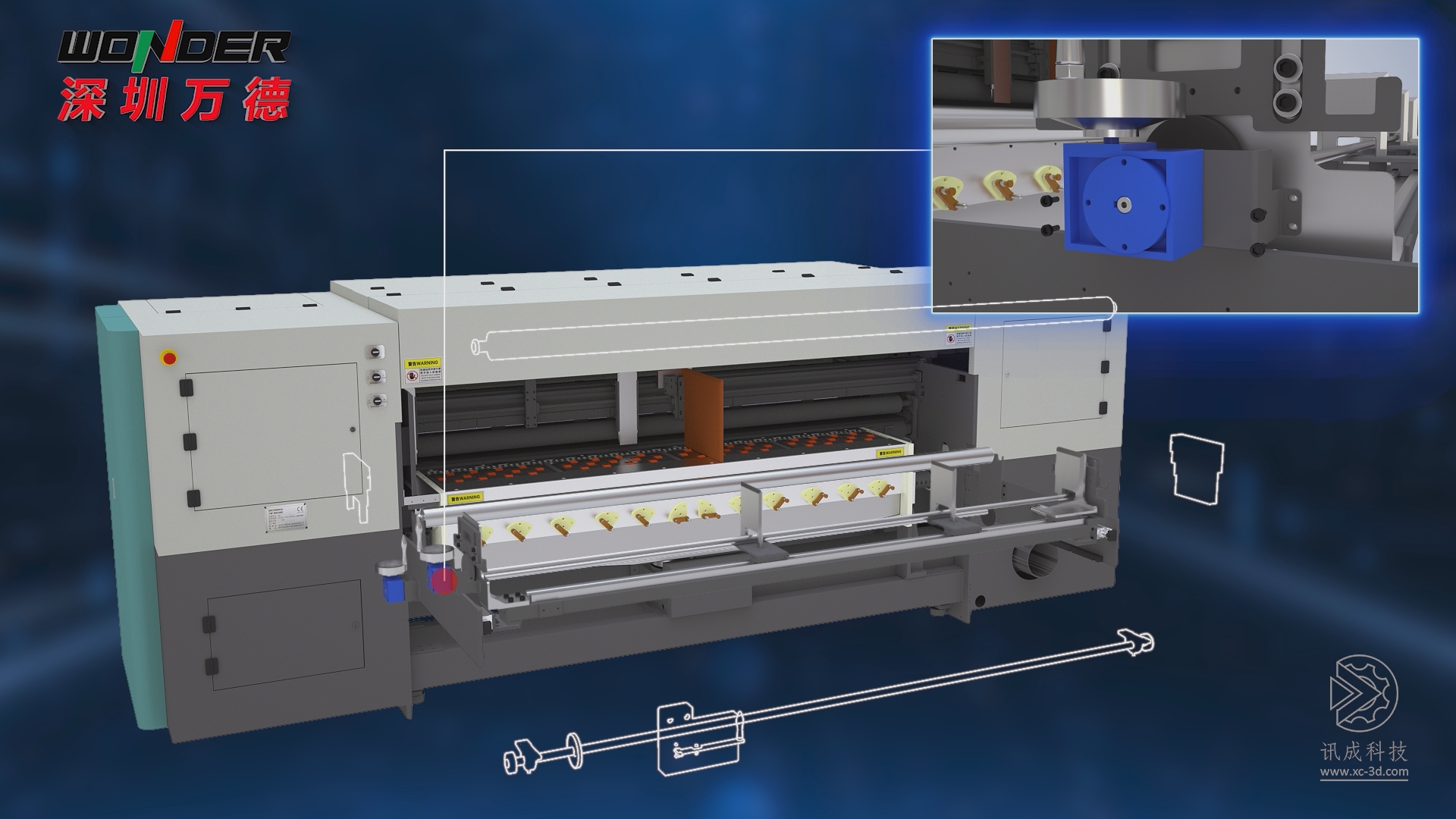

Accurate reproduction of fault phenomena changes the communication model of traditional after-sales service. Practices by Shenzhen Wande Digital Technology Co., Ltd. show that by establishing a visual case library of common faults through 3D animation, customers can accurately describe fault phenomena through animation, avoiding misunderstandings caused by unclear language. After receiving a repair request, after-sales engineers can immediately retrieve the corresponding fault animation to quickly understand the essence of the problem, increasing the initial diagnosis accuracy rate from the original 45% to 85%.

Dynamic display of internal mechanisms aids in-depth fault analysis. For complex faults such as print head clogging and ink supply system abnormalities in digital printing machines, 3D animation visually demonstrates the internal structure and working principles through cross-sections, allowing maintenance personnel to intuitively understand the root cause of the fault. Maintenance data for Wande Digital Printing Machines shows that with the assistance of 3D animation for diagnosis, the average repair time for complex faults has been reduced by 40%, and the repeat repair rate has decreased by 60%.

Standardized Repair: From Experience Dependence to Process Standardization

Visualized repair manuals improve service standardization. Traditional text-based repair manuals are converted into 3D interactive animations, clearly marking tool selection, disassembly sequence, and precautions for each repair step. Feedback from Wande Digital Printing Enterprises served by Xiamen Xuncheng indicates that after using 3D repair animations, the service quality variation among maintenance personnel with different technical levels has decreased from 35% to 15%, achieving standardized control of repair quality.

Visualization of key processes ensures repair accuracy. For the maintenance of precision components in digital printing machines, 3D animation clearly presents standard processes for key operations such as calibration and debugging through techniques like slow motion and multi-angle display. Maintenance personnel can master technical tricks that previously required years of experience by repeatedly watching and learning, increasing the first-time success rate of high-difficulty repairs by 50%.

Preventive Maintenance: From Passive Response to Proactive Prevention

Visualized maintenance guides drive maintenance model transformation. 3D animations demonstrate the daily maintenance points, cycles, and standards for digital printing machines, helping customers establish a scientific preventive maintenance system. Data shows that equipment regularly guided by maintenance animations has a 45% reduction in sudden failure rates, and the average time between failures has increased by 60%.

Self-service maintenance empowers reduced service reliance. By providing interactive 3D repair animations, customers' technical personnel can independently handle most common fault troubleshooting. Practice at a printing company shows that this empowerment model has reduced on-site service demand by 40%, while simultaneously improving customers' technical capabilities and equipment management levels.

Value Transformation: From Cost Control to Revenue Generation

Improved service efficiency directly reduces costs. Through the application of 3D animation, several efficiency indicators of digital printing machine after-sales service have significantly improved: average repair time shortened by 35%, travel costs reduced by 45%, and training efficiency increased by 60%. These improvements have reduced the total cost of after-sales service by over 30%.

Knowledge asset accumulation creates long-term value. Maintenance cases are continuously transformed into 3D animation resources, building the company's knowledge asset base. These animation resources not only serve current products but also provide valuable references for new product development and improvement, achieving continuous knowledge accumulation and value transformation.

Data-Driven: From Experiential Decision-Making to Precise Optimization

Service data analysis guides continuous improvement. By collecting usage data of 3D animations, analyzing fault frequencies, repair difficulties, and customer focus points, data support is provided for product improvement and service optimization. Personalized service push enhances service accuracy. Based on equipment models, usage environments, and historical records, targeted 3D animation content is pushed to customers. This precise service achieves a first-time problem resolution rate of 90%, significantly improving the service experience.

In the future, a 3D animation service system based on digital twins will achieve intelligent management of the entire equipment lifecycle. Through virtual-real mapping, real-time interaction, and intelligent prediction, it will provide enterprises with more accurate and efficient service solutions, continuously creating customer value and enterprise value.

FAQ Highlights:

Q: What benefits does equipment operation and maintenance animation bring to mechanical factories?

A: Paper operation manuals are outdated.

Equipment operation and maintenance animations are divided into six major categories: equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, equipment safety.

Benefits of demonstrating equipment operation and maintenance with animation:

1- Provide customers with more professional after-sales support. Equipment operation animations can quickly train new staff; equipment maintenance animations make maintenance more standardized, keeping equipment in peak condition; equipment repair animations allow customers to resolve common minor faults themselves, effectively improving equipment uptime; wear part replacement allows customers to flexibly schedule replacement times based on production needs; equipment assembly animations can significantly reduce reliance on experienced installation personnel; equipment safety animations can provide professional safety guidance and training materials for customers.

2- Effectively enhance customer loyalty. Practice shows that customers greatly prefer using animated demonstrations to solve various problems during equipment use, and animations are highly sticky to customers.

3- Significantly reduce the pressure on after-sales service, especially during the warranty period (some customers have calculated it can reduce unnecessary after-sales services by at least 30%-40%), and the effect is more pronounced with higher equipment output.

4- Become a sales weapon. Equipment factories that have produced equipment operation and maintenance animations offer a brand new concept to customers during marketing: worry-free equipment usage.

5- Reduce training costs, decrease equipment repair costs, and improve production efficiency.

6- Enhance brand image and market competitiveness, facilitating technical dissemination.

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., the paper feeding unit in a printing press mainly explains how to adjust baffles and gauges, and how to load paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Mechanical factories can also delete or deform sensitive equipment structures when providing equipment models.

The initiative is always in the hands of the mechanical factory.

Q: Which equipment is suitable for making operation and maintenance animations?

A: Almost all equipment is suitable for making operation and maintenance animations, from large single units costing millions to small ones costing tens of thousands or even thousands of yuan.

Creating operation and maintenance animations solves after-sales service issues on one hand, and on the other hand, it adds value to the company's brand and products, better promoting sales and increasing customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, clients span various types of enterprises including startup teams, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation for machinery and equipment, high-tech industries, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition booths or customer visits, whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animation. This not only brings a unique visual experience to customers but also quickly touches their hearts.