In the wave of digital transformation in manufacturing, 3D animation technology is deeply integrating into the entire lifecycle of manufacturing with its unique visualization advantages. From initial equipment installation simulation, to daily operations and maintenance management, and then to intelligent upgrades, this technology is reshaping manufacturing's operational models and value creation paths.

Installation Simulation: Precise Rehearsal from Blueprint to Reality

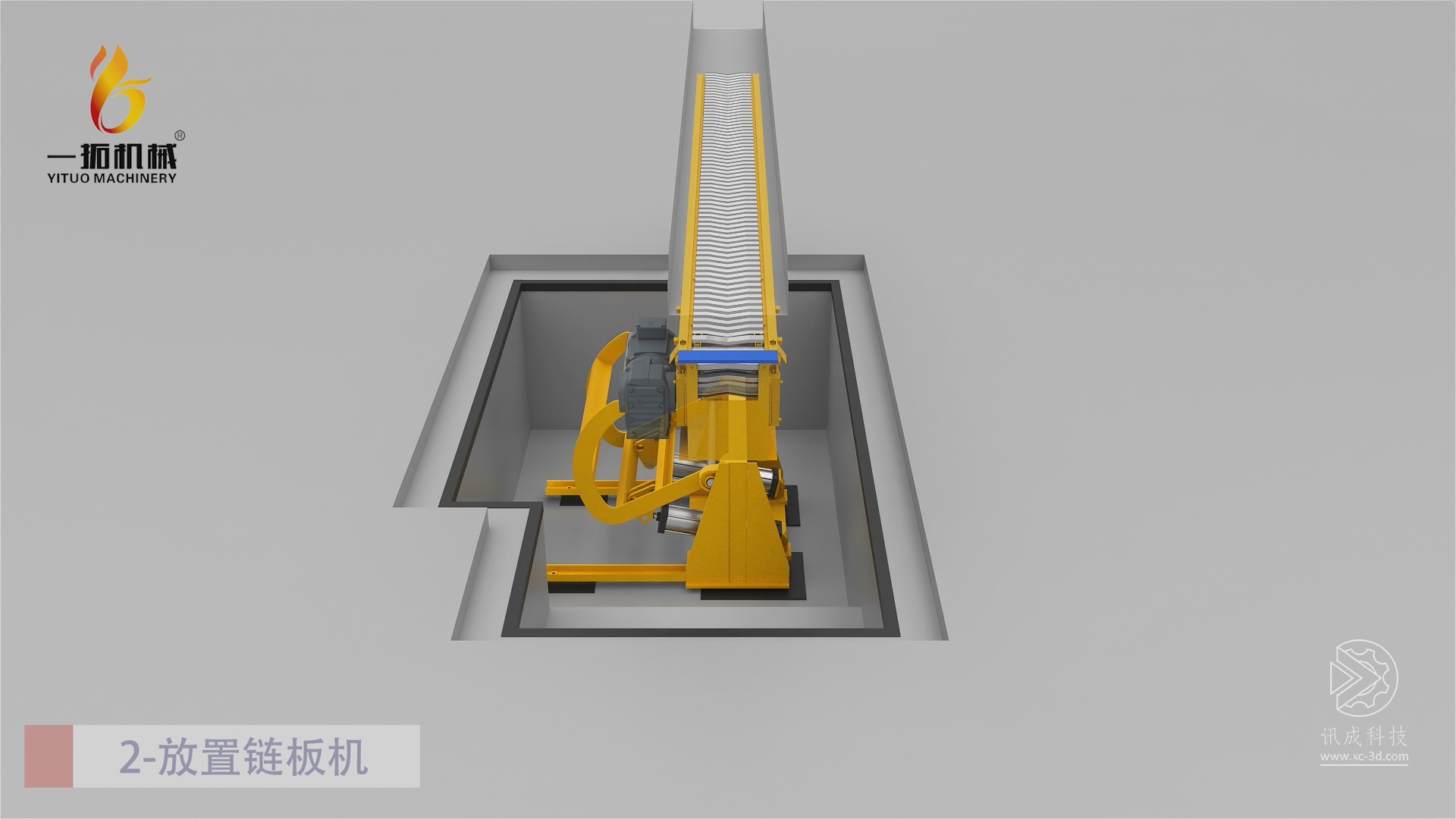

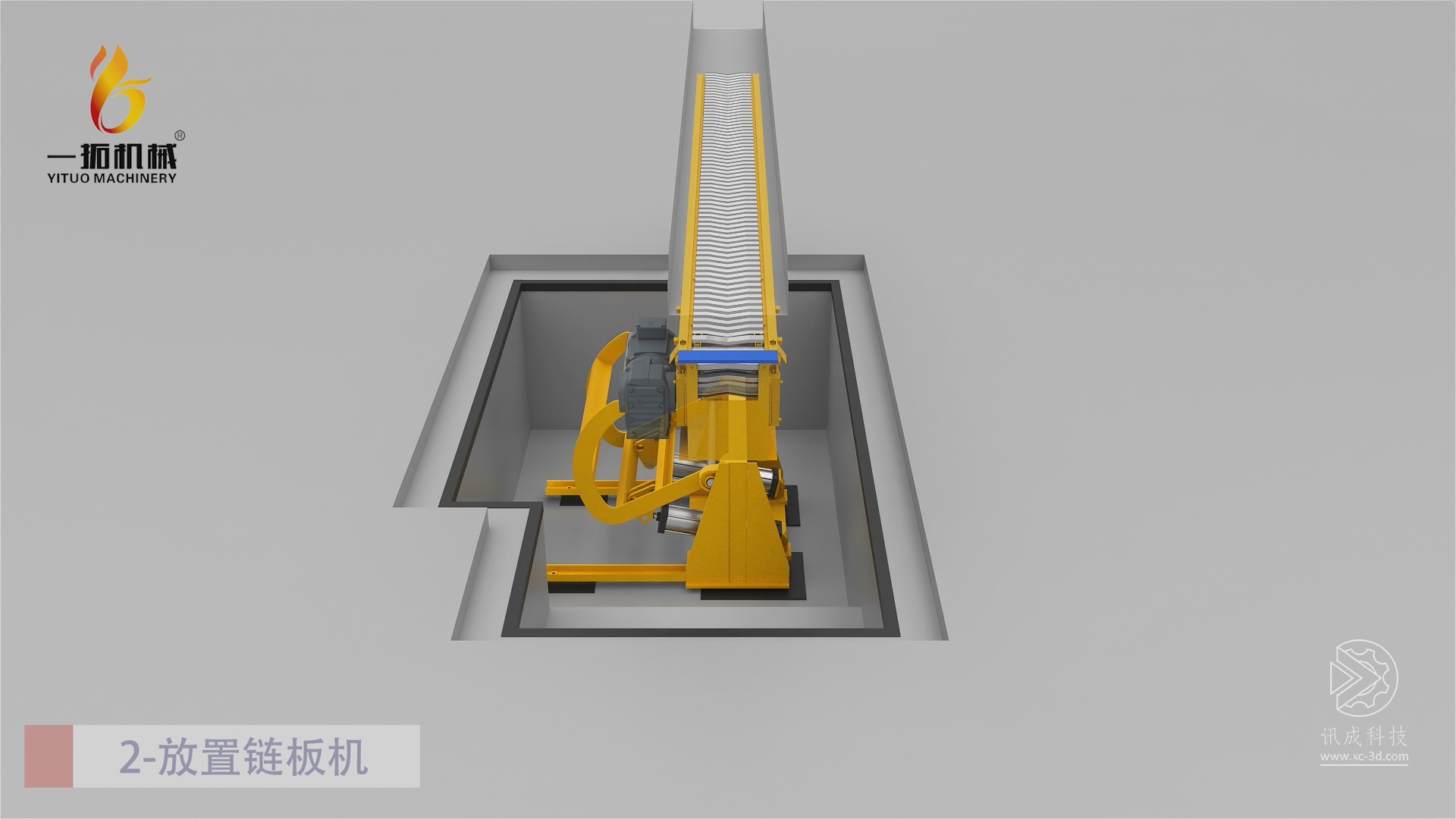

Equipment installation is a key link in the construction of manufacturing systems. Traditional installation processes often lead to schedule delays and cost overruns due to complex site conditions and coordination difficulties. 3D animation technology resolves issues before construction through precise installation simulations. In the equipment installation project of Shanghai Yituo Paper Machinery Co., Ltd., the entire production line installation process, including equipment positioning, pipeline layout, and space optimization, was pre-simulated using 3D animation, allowing engineers to effectively avoid potential installation conflicts.

The value of this rehearsal is not only in avoiding rework but, more importantly, in establishing a set of scientific installation standards. Through animation demonstrations, installation teams can clearly understand the technical requirements and operational specifications for each step, ensuring consistency and reliability in installation quality. Especially in the installation of large equipment, animations can precisely illustrate hoisting paths, installation sequences, and key precision control points, providing reliable guidance for on-site operations.

Operations & Maintenance Optimization: From Experience Dependency to Data-Driven

After equipment is put into operation, 3D animation continues to play an important role in operations and maintenance. Traditional equipment maintenance often relies on the personal experience of technicians, a model that is not only inefficient but also makes it difficult to ensure consistent maintenance quality. 3D animation standardizes and systematizes the maintenance process by converting personal experience into organizational knowledge through standardized maintenance guidance.

The practice of Shenzhen Wande Digital Technology Co., Ltd. fully demonstrates this value. The maintenance animations produced by the company for digital printing machines detail the entire process of daily checks, regular maintenance, and troubleshooting. By learning from animations, maintenance personnel not only acquire operational skills but also gain a deeper understanding of the equipment's working principles and key maintenance points. This in-depth understanding enables maintenance personnel to better prevent and handle equipment issues, significantly improving operational efficiency.

Smart Operations & Maintenance: From Reactive Response to Proactive Prevention

As manufacturing moves towards intelligence, the application of 3D animation in operations and maintenance is continuously deepening. By integrating with technologies like IoT and big data, 3D animation is driving the shift from reactive response to proactive prevention in maintenance models. The core of this transformation lies in 3D animation's ability to deeply integrate equipment operational data with 3D models, enabling real-time monitoring of equipment status and intelligent alerts.

In practical applications, this smart operations and maintenance system shows significant advantages. By analyzing equipment operational data, the system can predict component lifespan and issue early replacement alerts; by comparing with normal operating states, it can promptly detect anomalies and prevent failures; by optimizing maintenance schedules, it can minimize equipment downtime. This intelligent maintenance model not only enhances equipment reliability but also optimizes overall operational efficiency.

Skill Inheritance: From Master-Apprentice to Systematic Training

The sustainable development of manufacturing is inseparable from a robust talent training system. 3D animation technology completely transforms traditional skill inheritance methods through visual training. Compared to traditional training that relies on the personal experience of masters, systematic training based on 3D animation offers distinct advantages.

In the practice of Foshan Jinbing Machinery Co., Ltd., multi-language 3D training animations effectively solved the operational training challenges for overseas clients. Through standardized animated demonstrations, technicians from different linguistic backgrounds can accurately grasp the key points of equipment operation and maintenance. This training method not only improves training efficiency but also ensures accuracy and consistency in skill inheritance. The company has thus established a sustainable talent training mechanism, laying a solid foundation for business expansion.

Decision Support: From Vague Judgment to Precise Analysis

In the operational decision-making of manufacturing enterprises, 3D animation provides intuitive decision support. By visualizing complex equipment data and operational status, decision-makers can grasp situations more accurately and make scientific decisions. This visual decision support is particularly important for major decisions such as equipment upgrades and production line optimization.

The case of the American company Magui demonstrates this value. In equipment upgrade and modification projects, by simulating the effects of different modification plans using 3D animation, enterprise management can intuitively compare the pros and cons of each plan and make the optimal decision. This decision-making method based on visual analysis not only improves decision quality but also reduces decision risks.

Future Outlook: Digital Twin and Intelligent Integration

With the continuous development of technology, the application of 3D animation in manufacturing is evolving to higher levels. The maturity of Digital Twin technology will enable deep integration between the physical and virtual worlds. By building digital models that perfectly correspond to physical equipment, enterprises can simulate and optimize various aspects of production and operations in a virtual space.

This technological integration will usher in a new future for manufacturing. Enterprises can predict equipment performance changes, optimize production processes, and innovate operational models through Digital Twin systems. In this evolutionary process, 3D animation will continue to leverage its core visualization capabilities, providing strong support for the digital transformation of manufacturing.

From installation simulation to smart operations and maintenance, 3D animation is creating value across all levels of manufacturing. This technology not only enhances the efficiency and quality of manufacturing operations but, more importantly, drives the digital transformation and intelligent upgrading of manufacturing. For manufacturing enterprises committed to innovation and development, grasping this technological trend and deepening the application of 3D animation will be key to winning future competition.

Selected FAQs:

Q: What are the benefits of equipment installation animation?

A: The benefits of equipment installation animation are:

1. Significantly reduces reliance on experienced installation personnel;

2. Equipment installation is less prone to errors;

3. Facilitates new employee training;

4. Clients experience greater professionalism.

5. Reduces installation costs and risks.

Q: How to produce 3D animations related to equipment maintenance?

A: Most machine factories and production plants rely on experienced, qualified mechatronic engineers for equipment maintenance. Equipment maintenance animations can effectively address this issue.

1. It is recommended to first produce animations for common equipment failure points (including mechanical and electrical);

2. Record and document on-site maintenance to accumulate material for animation production;

3. Quantity: It is recommended to have about 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment initially; about 6-8 mechanical and 3-5 electrical for small and medium-sized equipment;

4. Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project interface personnel should be relatively stable.

Q: Will equipment usage animations expose sensitive equipment structures?

A: No.

Equipment usage animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., the feeding unit in a printing press mainly explains how to adjust the baffles and guides, and how to load materials; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machine factories can also delete or deform sensitive equipment structures when providing equipment models.

The control always remains with the machine factory.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with astonishing 3D animations. This not only brings a unique visual experience to clients but also deeply resonates with them.