In the field of industrial manufacturing, the precision and efficiency of equipment installation directly impact the quality and progress of the entire project. Traditional installation guidance relies mainly on 2D drawings and on-site experience, which suffer from low information transfer efficiency, delayed error detection, and difficulties in collaborative coordination. The introduction of 3D industrial animation technology is bringing revolutionary innovative practices to the field of industrial manufacturing installation.

Visual Pre-simulation of the Installation Process

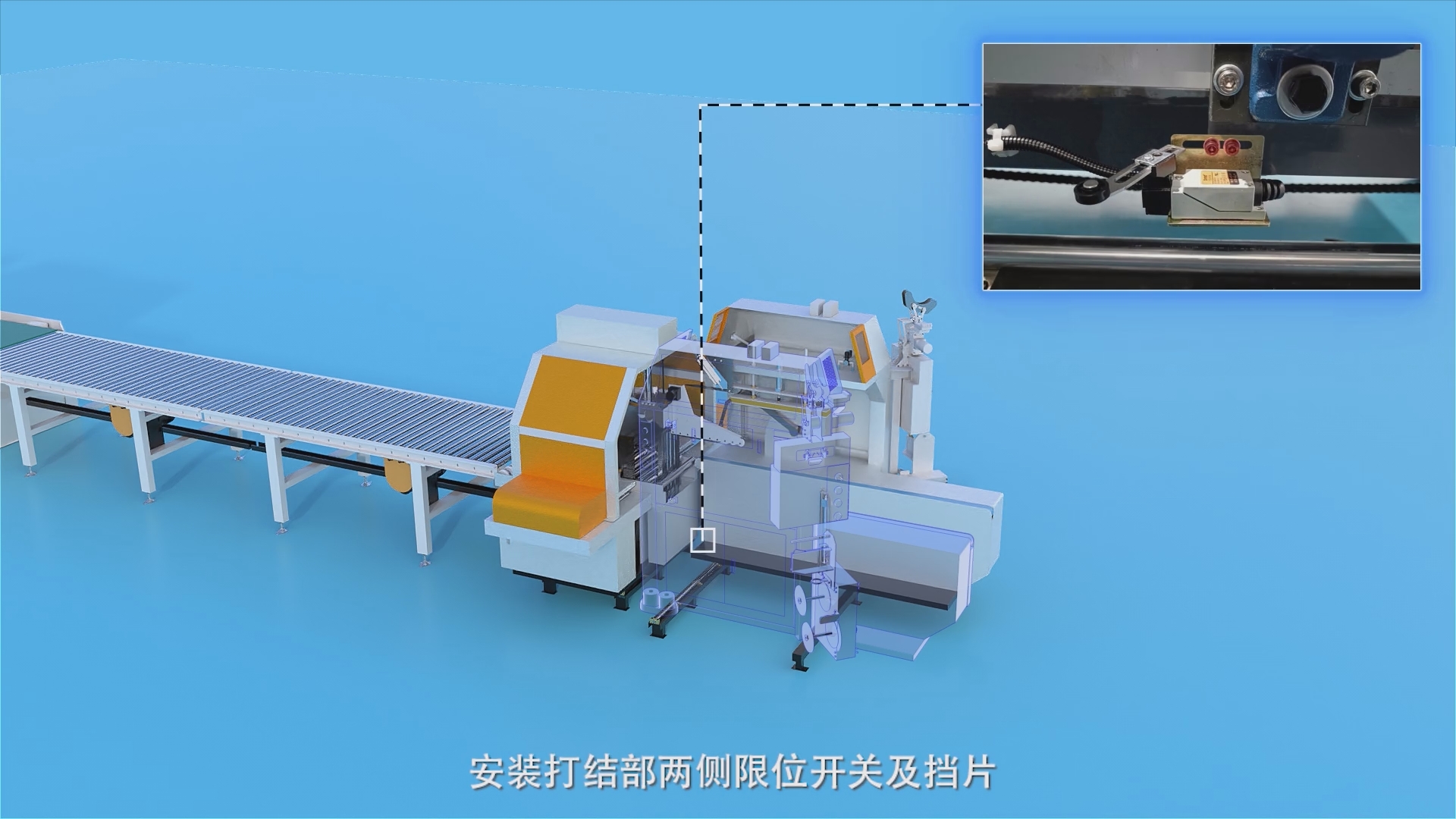

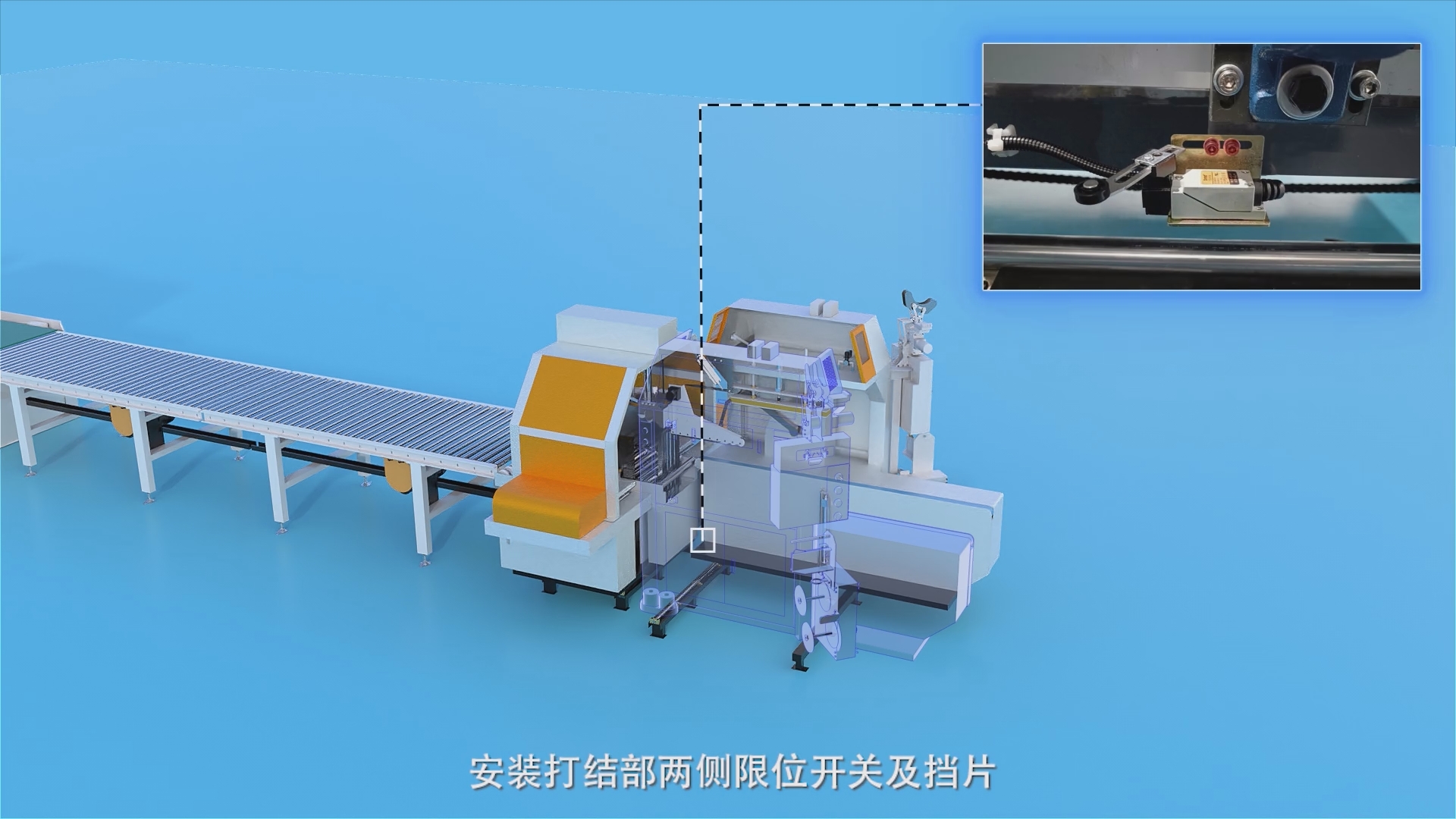

3D industrial animation achieves visual pre-simulation of the installation process through precise equipment modeling and installation process simulation. This pre-simulation not only showcases the final installation effect but also dynamically presents the entire installation flow, helping the engineering team fully grasp installation key points and potential issues before construction.

In the installation project of a corrugated paperboard production line for Shanghai Yituo Paper Machinery Co., Ltd., the 3D animation clearly demonstrated the complete process from foundation treatment, paper feeding platform installation, to chain plate machine positioning. Through multi-angle shots and close-ups, the animation highlighted the installation sequence and precision requirements of key components. This visual pre-simulation enabled the installation team to identify and resolve multiple design conflicts in advance, avoiding on-site rework and shortening the project installation cycle by 30%.

Digital Control of Installation Precision

In traditional installation processes, precision control often relies on the experience of technicians and measuring tools, posing a significant risk of human error. 3D industrial animation uses digital means to intuitively present installation precision requirements, providing clear quantitative standards for on-site operations.

In the installation of large equipment for Guangdong Zhaoqing Xijiang Machinery Manufacturing Co., Ltd., the 3D animation precisely marked the dimensional tolerances, leveling requirements, and connection standards for each installation step. Through animation demonstrations, installers could accurately understand the specific meanings and measurement methods of various precision indicators. This digital precision control method increased the first-time pass rate of installation quality from 75% to 92%.

Workflow Optimization for Collaborative Operations

Industrial equipment installation often requires collaborative coordination among multiple specialized teams. Traditional coordination methods are inefficient and prone to communication errors. 3D industrial animation establishes an efficient communication platform for all parties through a unified visual language, significantly improving the efficiency of collaborative operations.

In the automated production line installation project for Guangdong Jinshun Automation Technology Co., Ltd., the 3D animation clearly delineated the interfaces and connection points for different specialized teams, such as mechanical, electrical, and automation. Each team understood its role and tasks within the overall installation process through the animation, achieving precise collaborative work. This optimized collaborative workflow resolved issues that previously required multiple coordination meetings, allowing for quick consensus through animation demonstrations.

Technological Innovation in Remote Guidance

In the context of global manufacturing, equipment installation often requires cross-regional technical support. The integration of 3D industrial animation with remote communication technology provides innovative solutions for remote installation guidance, effectively addressing issues of uneven expert resource allocation.

The case study from Guangdong Zhaoqing Xijiang Machinery shows that through a 3D animation remote guidance system, on-site installers can receive real-time visual guidance from experts. Experts can precisely convey installation key points and precautions through animation annotations and real-time communication. This remote guidance model not only improves problem-solving efficiency but also significantly reduces expert travel costs, shortening the average response time for remote installation projects by 70%.

Systematic Construction of Knowledge Management

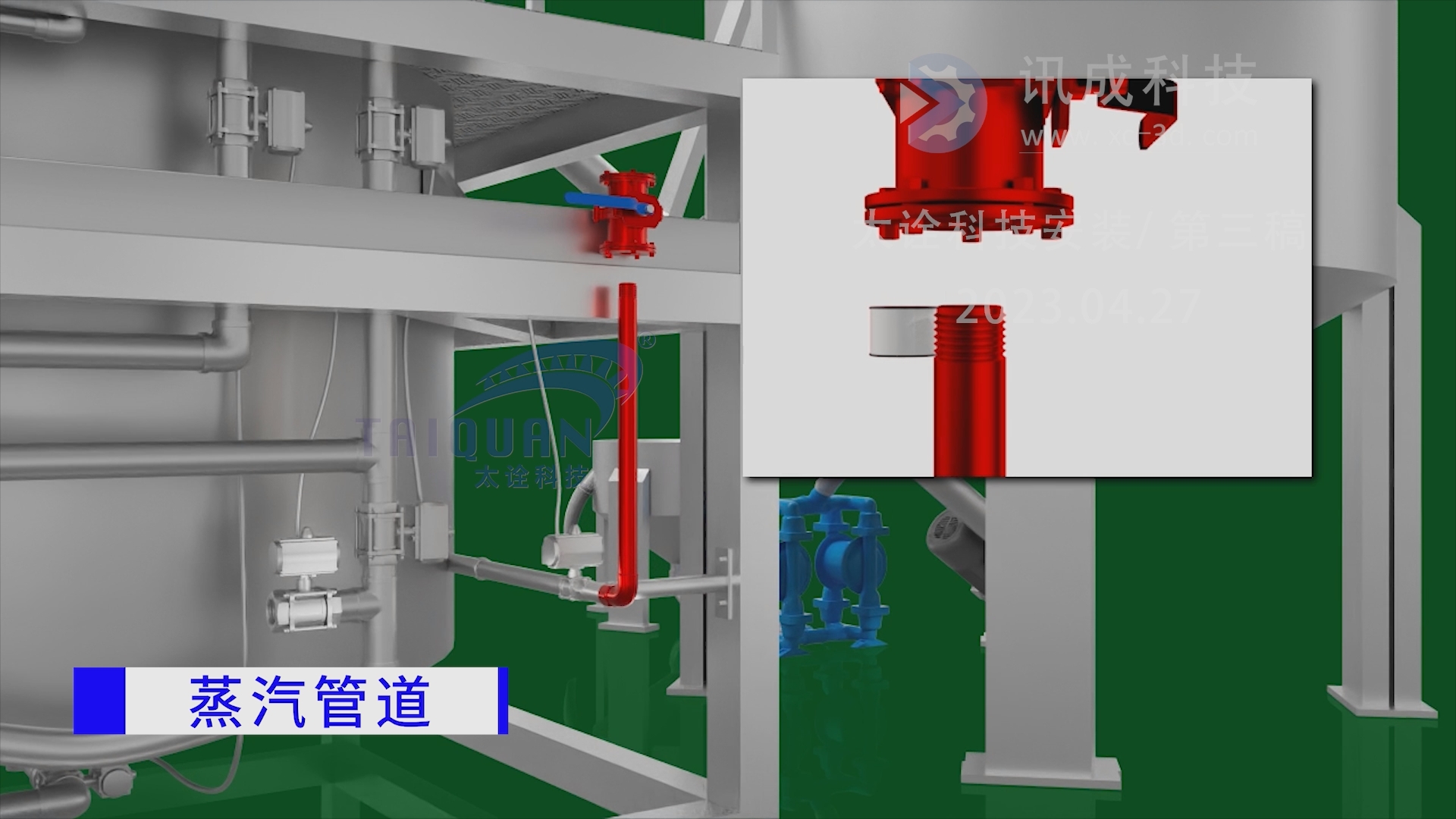

3D industrial animation technology also provides innovative tools for knowledge management in the installation field. By transforming excellent installation practices and lessons learned into standardized animation content, companies establish a continuously accumulating knowledge management system.

Guangzhou Taiquan Automation Technology Co., Ltd. has accumulated a large number of installation cases and best practices through its 3D animation system. When starting new projects, engineering teams can quickly retrieve relevant cases and learn from past experiences. This systematic knowledge management not only improves installation efficiency but also ensures the consistency of engineering quality. Company statistics show that by applying the animation knowledge base, the installation plan design time for new projects has been reduced by 40%, and installation quality stability has increased by 35%.

Intelligent Trends for Future Development

With technological advancements, the application of 3D industrial animation in installation guidance is evolving towards intelligence. The introduction of digital twin technology enables real-time data interaction between virtual models and physical equipment; the application of augmented reality technology allows installation guidance information to be directly overlaid onto real scenes; the development of artificial intelligence algorithms provides intelligent decision support for installation plan optimization.

The convergence of these technologies will drive industrial installation guidance into a new intelligent phase. Future installation guidance systems will be able to automatically adjust guidance content based on real-time data, intelligently recommend optimal installation solutions based on site conditions, and truly achieve digital and intelligent management of the installation process.

3D industrial animation technology is profoundly changing the operational modes and management concepts in the industrial manufacturing installation field. From visual pre-simulation to digital control, from process optimization to knowledge management, its innovative value has been validated across multiple dimensions. With continuous technological progress and deepening applications, 3D industrial animation will undoubtedly play a greater role in industrial manufacturing installation, driving the industry towards more efficient and intelligent development.

Featured FAQs:

Q: What are the benefits of equipment installation animation?

A: The benefits of equipment installation animation are:

1- Greatly reduces reliance on experienced installers;

2- Equipment installation is less prone to errors;

3- Facilitates training of new personnel;

4- Customers perceive a more professional service.

5- Reduces installation costs and risks.

Q: What categories does Xuncheng animation video production cover?

A: Animation video production includes the following three categories:

Promotional: Includes product promotion, corporate promotion, etc.

Technical: Includes equipment operation, maintenance, repair, consumable part replacement, assembly, safety, etc.

Customized: Includes videos for exhibitions, investment promotion, event openers, etc.

Q: Is equipment usage animation expensive?

A: To conclude upfront: Equipment usage animation generates benefits for machinery factories. The greater the investment, the greater the return.

The production cost for equipment usage animation generally ranges from tens of thousands to over a hundred thousand, or even higher. While it may seem expensive on the surface, the average cost per piece of equipment is not high.

How does equipment usage animation create benefits for machinery factories?

1- Low amortized cost. Machinery equipment typically undergoes minor modifications every 2 years and major ones every 4 years. The total cost of animation video production amortized per unit is very low;

2- Equipment premium. According to actual measurement data from machinery factories, every 1 yuan invested in producing equipment operation and maintenance animations generates a sales premium of approximately 3-5 yuan, a 3-5 fold return);

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively enhances customer loyalty;

5- Provides a competitive edge over similar products.

Features: Significant initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech, software development, foreign trade companies, and more. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with breathtaking 3D animations. This not only brings a unique visual experience to clients but also deeply impresses them.