In the current increasingly fierce manufacturing competition environment, after-sales service has become an important part of the core competitiveness of enterprises. Traditional after-sales service models face many challenges such as slow response speed, high cost, and low efficiency, while the application of 3D industrial animation technology is bringing revolutionary changes to manufacturing after-sales service.

Visual Guidance: Reducing Reliance on On-site Service

Remote fault diagnosis and guidance are the primary application scenarios for 3D industrial animation in after-sales service. Taking the ink printing machine repair animation produced by Xiamen Xuncheng for Guangdong Tuopin Intelligent Machinery Technology Co., Ltd. as an example, through precise 3D demonstration, complex repair processes are transformed into intuitive visual guides. When a customer's equipment fails, technical service personnel can remotely retrieve corresponding animation clips to guide on-site operators to complete basic fault diagnosis and repair. Practice data shows that this model allows about 40% of routine problems to be solved remotely, reducing the cost per service by more than 60%, and shortening the average problem resolution time from the original 48 hours to within 4 hours.

Precise disassembly and assembly guidance significantly improved repair efficiency. The digital printing machine repair animation by Shenzhen Wande Digital Technology Co., Ltd. clearly shows the disassembly and assembly sequence of parts and key precautions through exploded views. After-sales feedback indicates that with animation guidance, the average work time for maintenance personnel was reduced by 35%, and the rework rate due to errors decreased by 50%. Especially in the maintenance of precision equipment, the visualization of key parameters such as tolerance fit and installation torque in the animation effectively prevents secondary damage caused by improper operation.

Standardized Training: Accelerating Technical Capability Transfer

Rapid training of new employees is the core value of 3D animation training. The multilingual 3D training animation for Foshan Jinbing Machinery Co., Ltd. systematically covers the entire process of equipment operation, maintenance, and repair. Through the animation training system, newly recruited after-sales service engineers can master the maintenance skills of core equipment within 3 weeks, shortening the training period by 50% compared to the traditional apprenticeship model. This standardized training method not only improves training efficiency but also ensures the stability of technical service quality.

Visualization of complex processes deepens technical understanding. The corrugated roller maintenance animation by American Magg BW Papersystems, through professional techniques such as slow motion and local perspective, clearly demonstrates the maintenance points and process standards of core components. This in-depth visualization enables maintenance personnel not only to grasp the operating procedures but also to understand the technical principles, thus enabling them to respond flexibly to emergencies. After implementing this animation training, the incidence of unexpected equipment failures decreased by 30%, and the equipment's service life was significantly extended.

Preventive Maintenance: Controlling Service Costs from the Source

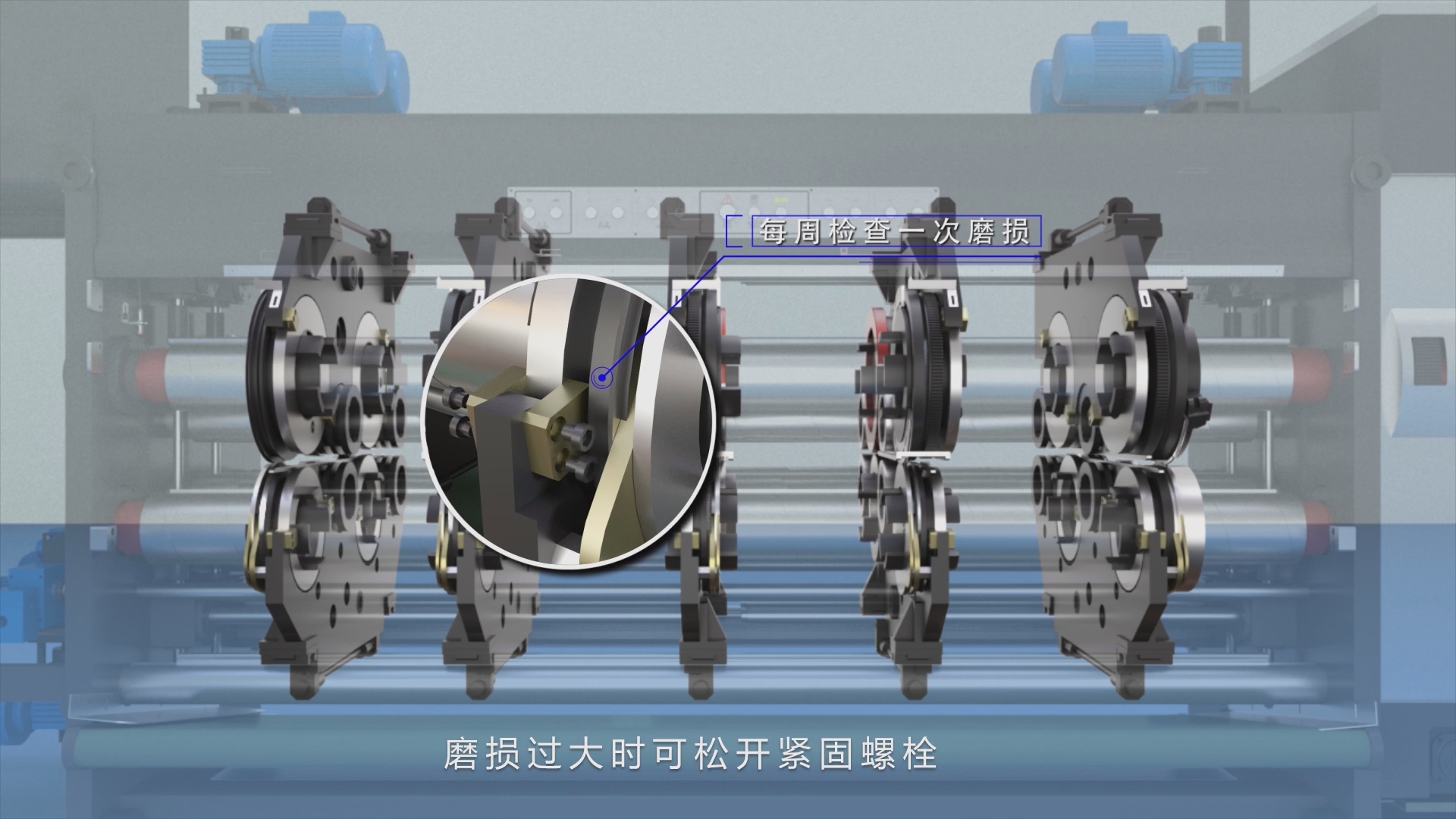

Standardization of maintenance processes effectively avoids maintenance omissions. The flexographic printing press maintenance animation for Xiamen Sanlei Packaging Materials Co., Ltd. clearly marks the location, maintenance cycle, and operating standards of each maintenance point. After customers establish a preventive maintenance plan according to the animation guidance, the execution rate of regular equipment maintenance increased from 65% to 90%, and the rate of unexpected equipment downtime decreased by 25%. This preventive maintenance model not only improves equipment reliability but also significantly reduces the cost of emergency repairs.

Optimization of spare parts management reduces inventory capital occupation. The 3D training animation for Ruichang Carton Machinery Manufacturing Co., Ltd. clearly displays the location of easily worn parts, replacement standards, and warning indicators. Customers can develop precise spare parts procurement plans based on the animation guidance, achieving significant results such as a 25% reduction in spare parts inventory costs and a 40% increase in inventory turnover rate, while ensuring normal equipment operation.

Knowledge Management: Building Core Corporate Assets

Digitalization of technical experience enables efficient knowledge transfer. The electromagnetic temperature control system maintenance animation for Dongguan Xusen Intelligent Technology Co., Ltd. transforms the maintenance experience of senior engineers into standardized 3D content. This knowledge accumulation mechanism ensures that the company's core technology no longer relies on individual experts but forms replicable and inheritable organizational assets. When senior engineers change positions, their experience is fully preserved and benefits the entire service team.

Multilingual support enhances global service capabilities. The IGV intelligent forklift animation by Fujian Fangguangshengshi Information Technology provides multiple language versions, effectively resolving language barriers in overseas services. Technical service personnel can communicate effectively with customers through the visual language of animation, even if they do not speak the same language. This initiative has shortened the company's international service response time by 40% and significantly improved customer satisfaction.

Future Outlook: A New Stage of Intelligent Services

3D industrial animation is profoundly changing the traditional model of manufacturing after-sales service through multiple approaches such as visual guidance, standardized training, and preventive maintenance. Its practical value has been fully verified in cost control, efficiency improvement, and technical transfer. For manufacturing enterprises pursuing excellent service, accelerating the application of 3D industrial animation in after-sales service is not only a strategic choice to enhance competitiveness but also a necessary path for digital transformation. With the development of technologies such as the Internet of Things and artificial intelligence, the application of 3D industrial animation in manufacturing after-sales service is entering a new stage.

FAQ Highlights:

Q: Will operation and maintenance animations expose sensitive structures of the equipment?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., the feeding unit of a printing press mainly explains how to adjust the baffle and side guide, and how to feed materials; the printing unit mainly explains how to apply ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Machinery manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The initiative is always in the hands of the machinery manufacturer.

Q: Are operation and maintenance animations very expensive?

A: To conclude first: Equipment operation and maintenance animations create benefits for machinery manufacturers. The greater the investment, the greater the return.

The cost of producing equipment operation and maintenance animations generally ranges from tens of thousands to over a hundred thousand yuan, or even higher. While it may seem expensive on the surface, the average cost per piece of equipment is not high.

How do equipment operation and maintenance animations create benefits for machinery manufacturers?

1- Low average cost. Machinery equipment typically undergoes minor modifications every 2 years and major modifications every 4 years. The total cost of producing animated videos is very low when averaged across each machine;

2- Equipment premium. According to actual measurements by machinery manufacturers, every yuan invested in producing equipment operation and maintenance animations generates an equipment sales premium of about 3-5 yuan, i.e., a 3-5 times return);

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively increases customer loyalty;

5- More competitive compared to similar products.

Characteristics: Significant upfront investment, minimal subsequent investment.

Q: Do small accessory parts need operation and maintenance animations?

A: Equipment operation and maintenance animations are generally divided into six categories: Equipment Operation, Equipment Maintenance, Equipment Repair, Replacement of Wear Parts, Equipment Assembly, and Equipment Safety.

It is generally not necessary to produce animations for all small accessory parts. It is recommended to create animations for equipment maintenance, equipment assembly, and common fault repairs.

1- Small accessory parts are generally attached to large equipment, making it harder to establish a brand;

2- Apply watermarks to the animated videos to continuously reinforce the brand with customers;

3- Animated videos have wider dissemination and higher transmission efficiency;

4- Animated videos allow small accessory parts to command a higher premium.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at trade shows or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animations. This not only brings a unique visual experience to clients but also quickly resonates with them.