In the industrial manufacturing sector, the precision and efficiency of equipment operation directly impact production quality and cost. Traditional operation guidance relies on paper manuals and master-apprentice models. This knowledge transfer method, based on text and verbal communication, often struggles to accurately convey operational essentials and safety regulations when dealing with modern industrial equipment that is complex in structure and precise in craftsmanship. With the acceleration of industrial digitalization, 3D industrial animation, with its unique technical advantages, is driving equipment operation towards a technical leap from visual presentation to functional realization.

Visualized Operation: Reconstructing Equipment Cognition Patterns

3D animation technology fundamentally changes how operators perceive complex equipment. Through precise dynamic demonstrations and multi-angle perspectives, it transforms abstract textual descriptions into intuitive visual language, enabling operators to establish a complete equipment cognition framework before actual operation. This shift in cognition not only lowers the barrier to technical understanding but also subconsciously builds a mindset for standardized operation.

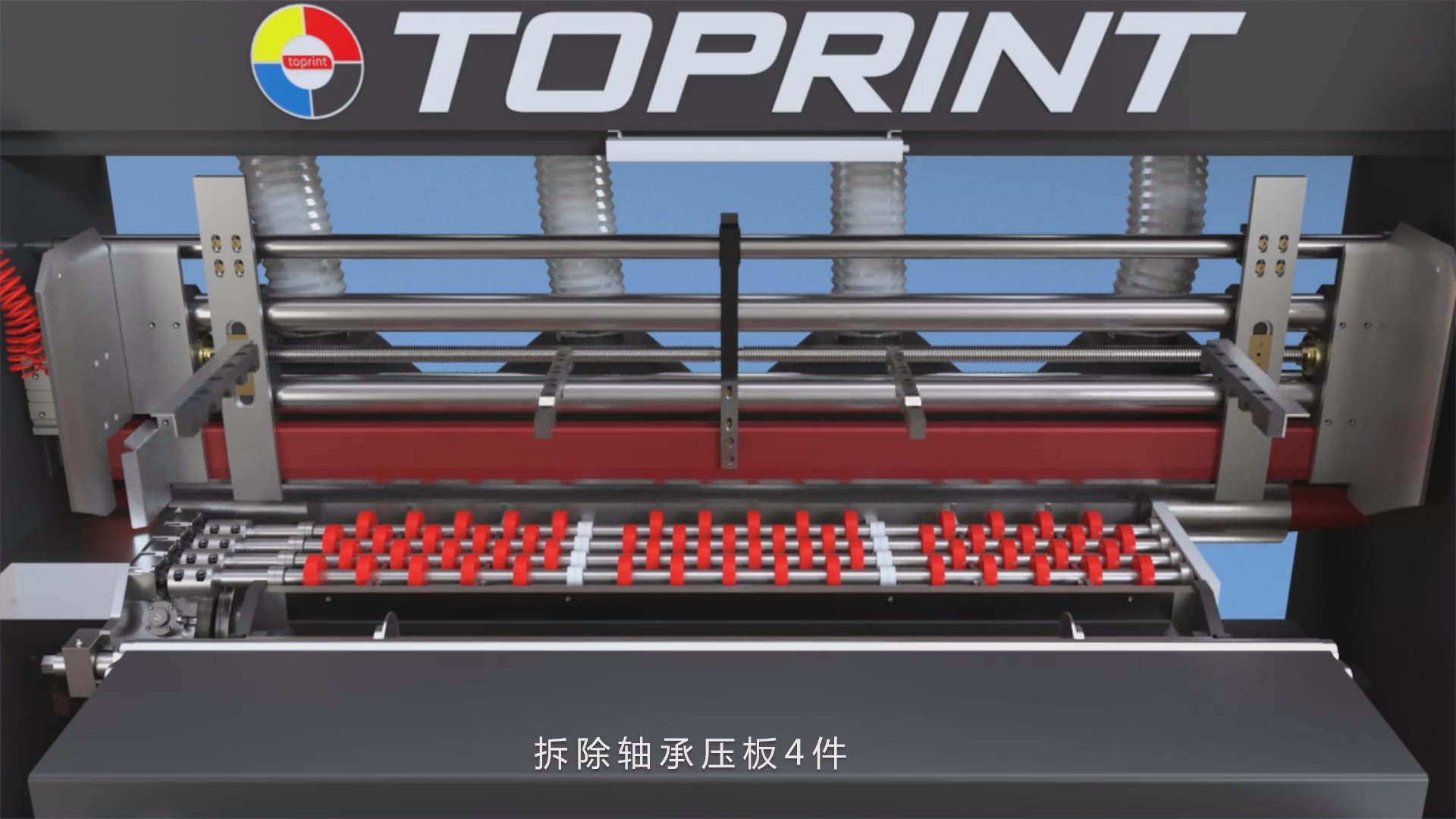

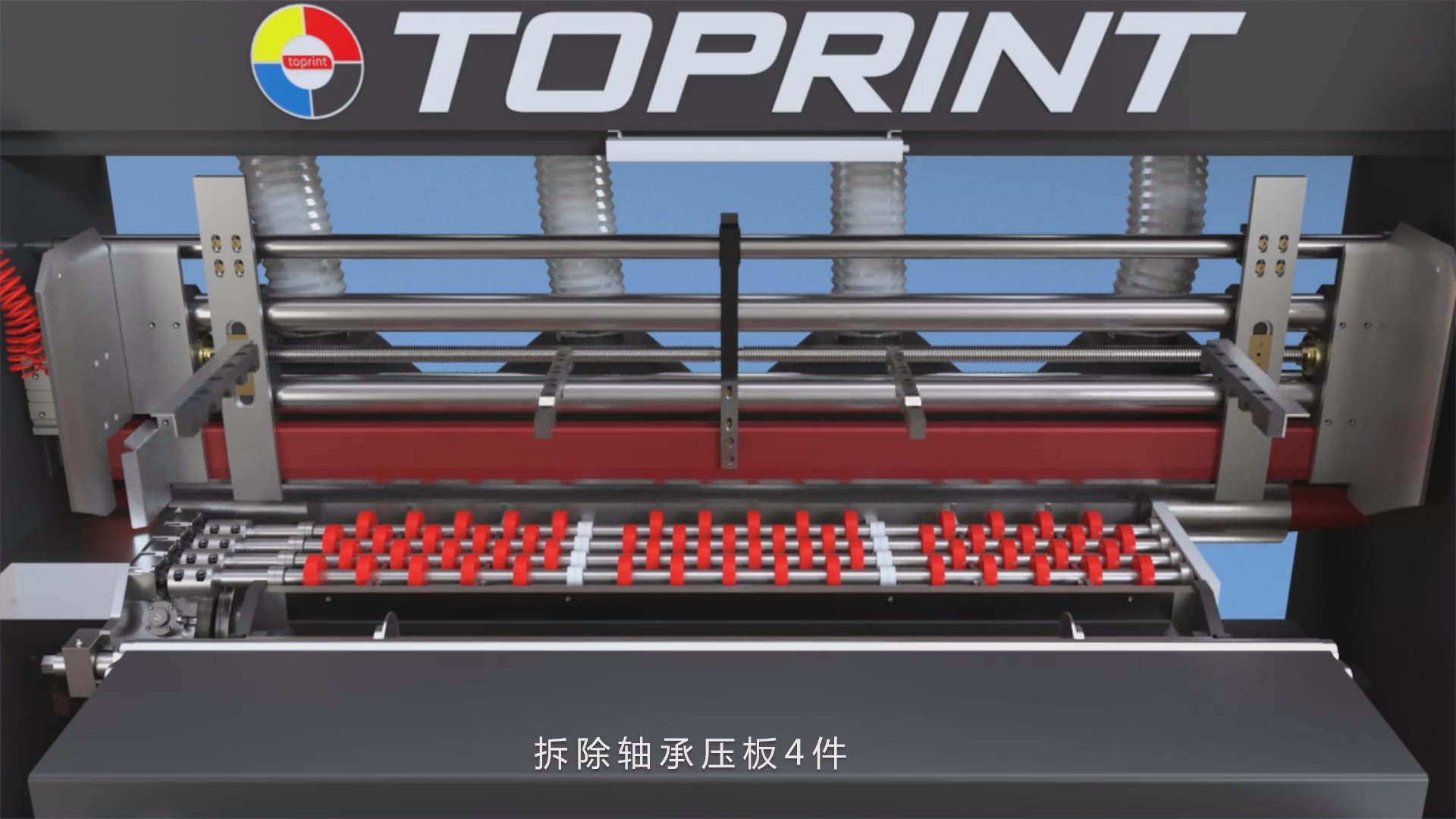

In serving Guangdong Topin Intelligent Machinery Technology Co., Ltd., 3D animation, with its precise temporal control and spatial display capabilities, fully presented the operational procedures and key maintenance points of a water-based ink printing machine. This visual guidance allows operators to anticipate the chain reactions of each operational step, thus exhibiting higher accuracy and adaptability in real operations.

Standardized Empowerment: Establishing a Replicable Skill Inheritance System

The effectiveness of traditional operation training is often limited by the trainer's individual experience and communication skills. In contrast, 3D animation builds a standardized knowledge transfer system. It solidifies best operational practices into repeatable and verifiable visual content, ensuring that every operator receives uniform and standardized training.

The flexographic printing press operation animation for Xiamen Sanlei Packaging Materials meticulously demonstrates the complete process from equipment startup, parameter setting, operational monitoring, to normal shutdown. This standardized dynamic guidance enables operators of different shifts and experience levels to maintain a uniform operational standard, leading to a 30% improvement in product quality stability. This innovative training method not only shortens the skill inheritance cycle but also builds a knowledge base of operational practices that can be continuously accumulated at the organizational level.

Functional Leap: From Operational Execution to Process Understanding

The deeper value of 3D animation lies in facilitating the role transformation of operators from 'executors' to 'understanders.' By revealing the internal structure and working principles of the equipment, it helps operators establish the cause-and-effect relationship between operational actions and equipment responses, thereby achieving more precise and flexible operations based on understanding.

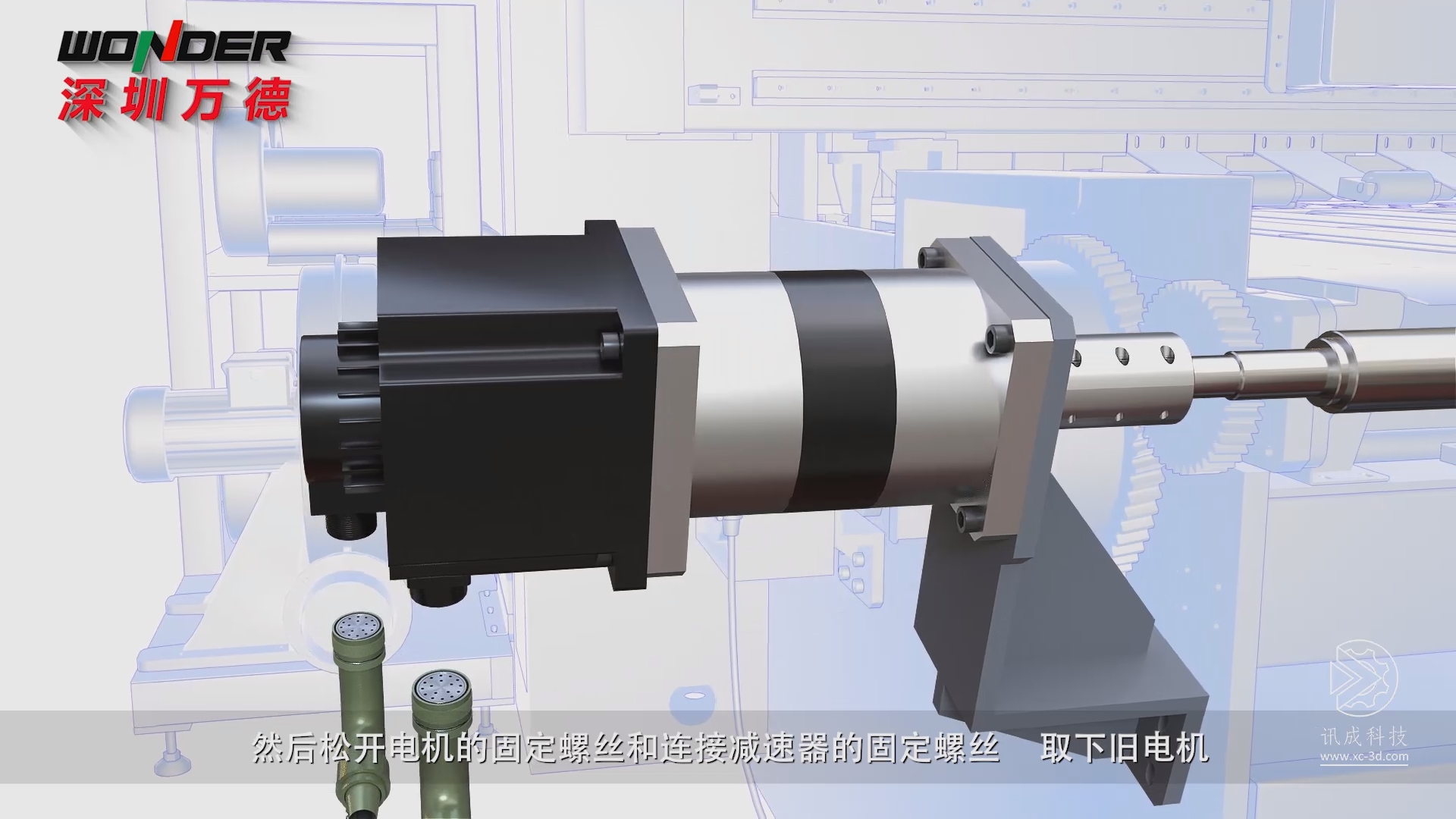

The case of Shenzhen Wande Digital Technology Co., Ltd. fully embodies this leap. Through the in-depth display of the equipment's internal layout and working logic via 3D animation, operators not only master 'how to operate' but also understand 'why they operate this way.' This deep cognition leads to a fundamental improvement in operational accuracy and provides valuable insights from the front lines for equipment optimization and process improvement.

Systematic Integration: Building the Foundation for Digital Operations

In the context of Industry 4.0, 3D animation is evolving from an independent training tool into a crucial component of enterprise digital systems. It standardizes equipment operation through visualization, providing underlying support for digital management within enterprises.

Foshan Jinbing Machinery Co., Ltd. has achieved standardized global service through multilingual 3D animation. This knowledge management system, centered around 3D models, not only resolves current language barriers but also lays the visual foundation for the enterprise to build a digital twin system and achieve data-driven intelligent operations.

3D industrial animation is redefining the technical boundaries of equipment operation. Through visualized cognition, standardized inheritance, in-depth understanding, and systematic integration, it achieves a technical leap in equipment operation from simple visual presentation to complex functional realization. With the deepening development of the industrial internet and intelligent manufacturing technologies, 3D animation will no longer be merely an auxiliary tool for operation but will become a key link connecting personnel skills with equipment efficiency, continuously driving manufacturing towards digitalization and intelligence.

Featured FAQs:

Q: What are the benefits of equipment operation and maintenance animations for machinery factories?

A: Paper operation manuals are outdated.

Equipment operation and maintenance animations are divided into six major categories: equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, and equipment safety.

Benefits of demonstrating equipment operation and maintenance with animations:

1- Provides customers with more professional after-sales support. Equipment operation animations can quickly train new staff; equipment maintenance animations ensure more standardized maintenance, keeping equipment in peak condition; equipment repair animations allow customers to resolve common minor faults themselves, effectively increasing equipment utilization; wear part replacement facilitates flexible scheduling by customers based on production needs; equipment assembly animations can significantly reduce reliance on experienced installation personnel; equipment safety animations provide professional safety guidance and training materials for customers.

2- Effectively enhances customer loyalty. Practice shows that customers greatly appreciate using animated demonstrations to solve various issues during equipment use, making animations highly effective in retaining customers.

3- Significantly reduces the pressure on after-sales service, especially during the warranty period (some customers have calculated it can reduce unnecessary after-sales service by at least 30%-40%), and the effect is more pronounced with a larger volume of equipment shipped.

4- Becomes a powerful sales tool. Equipment manufacturers that have produced operation and maintenance animations can present a novel concept to customers during marketing: 'Worry-free equipment usage.'

5- Reduces training costs, decreases equipment repair expenses, and improves production efficiency.

6- Enhances brand image and market competitiveness, facilitating knowledge dissemination.

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in video format (e.g., in a printing press, the paper feeding unit mainly explains how to adjust baffles and guides, and how to feed paper; the printing unit explains how to apply ink, change plates, and adjust printing pressure. These do not involve sensitive equipment structures). Machinery factories can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always remains with the machinery factory.

Q: How can small companies without an 'Equipment Operation Manual' create operation and maintenance animations?

A: Xuncheng can provide a full-chain service for creating equipment operation and maintenance animations. Specifically:

1- After the equipment is installed and debugged, the machinery factory can record on-site training using multiple fixed cameras and convert it into documentation (Xuncheng can also provide this service).

2- Xuncheng will categorize and optimize the relevant content.

3- The documentation will be sent to the machinery factory for confirmation.

4- Animation production will commence.

About Xuncheng Technology

Founded in 2016, with 9 years of professional experience in industrial 3D animation creation, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, and foreign trade companies. We offer a one-stop industrial 3D animation creative service, from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibitions or during client visits, whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animation. This not only brings a unique visual experience to clients but also quickly resonates with them.