Driven by the wave of Industry 4.0 and intelligent manufacturing, equipment operations and maintenance (O&M) are undergoing a profound transformation from traditional passive maintenance to intelligent predictive O&M. This shift not only requires advanced data collection and analysis technologies but also the conversion of complex O&M knowledge into intuitive and understandable visual language. 3D animation technology, with its unique visualization advantages, is painting an innovative picture of smart O&M practices in the field of industrial maintenance.

Precise O&M: Building a Standardized Maintenance Workflow System

The primary prerequisite for achieving smart O&M is to establish standardized operating procedures. Through dynamic simulation, 3D animation transforms abstract maintenance manuals into concrete operational guides, providing clear work specifications for maintenance personnel. When serving Guangdong Toprint Intelligent Machinery Technology Co., Ltd., we accurately reproduced the core maintenance process of a high-speed ink printing machine using 3D animation. This visual guidance not only prevented secondary damage caused by incorrect operating sequences but also reduced the average maintenance time by 30%, effectively improving the overall equipment utilization rate.

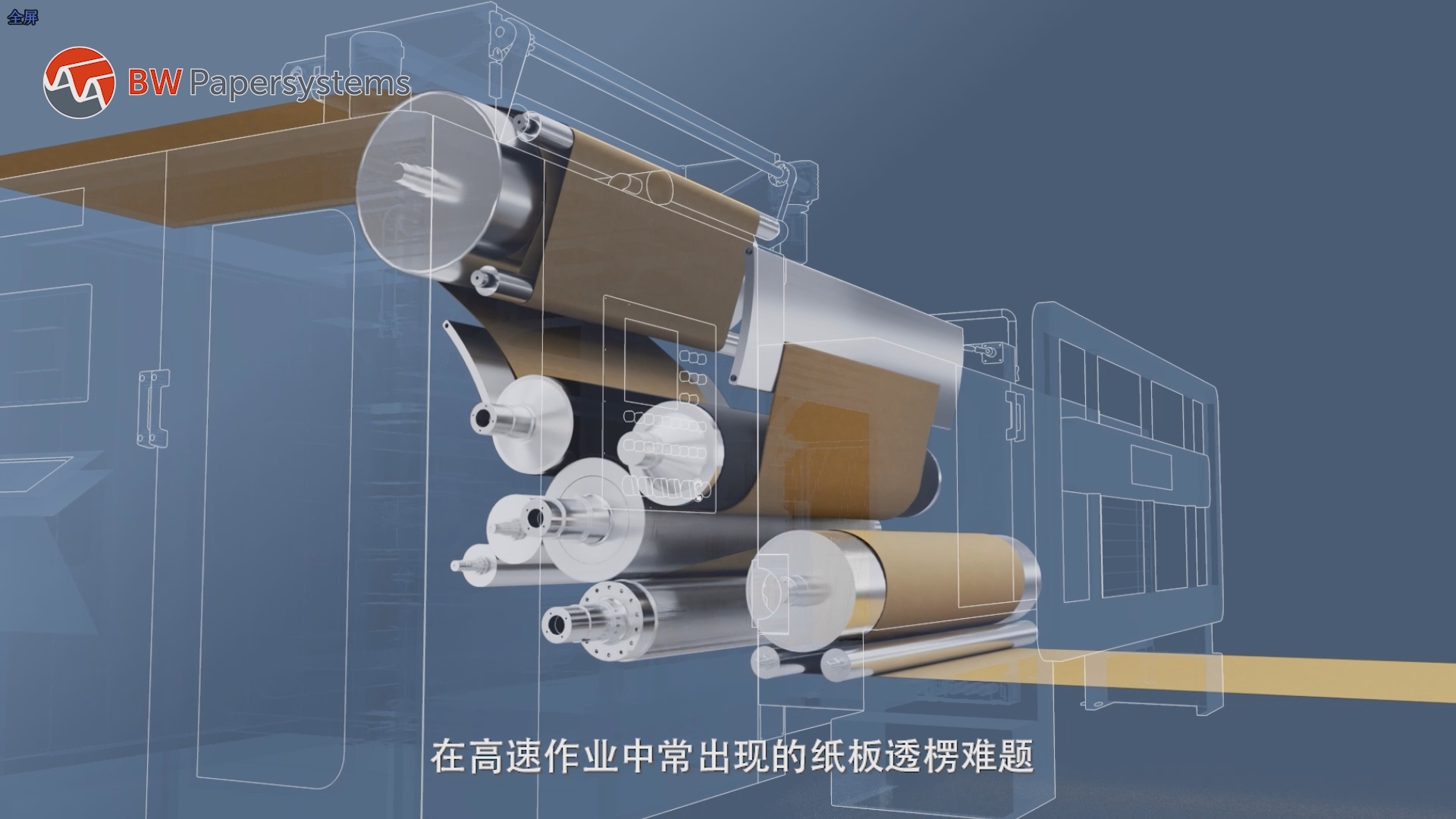

In-depth Perspective: Achieving Holographic Cognition of Equipment Systems

Smart O&M is built upon a deep understanding of equipment operating principles. Through multi-dimensional perspective and dynamic cross-sections, 3D animation breaks the limitations of traditional cognition. For the corrugated cardboard production line project of BW Papersystems USA, holographic visualization of the internal structure of the equipment was achieved through 3D animation. This technology clearly presented the precise structure of the corrugated rollers and the paperboard forming process, providing an intuitive solution to the long-standing industry challenge of 'corrugation penetration' and promoting the upgrade of industry technical standards.

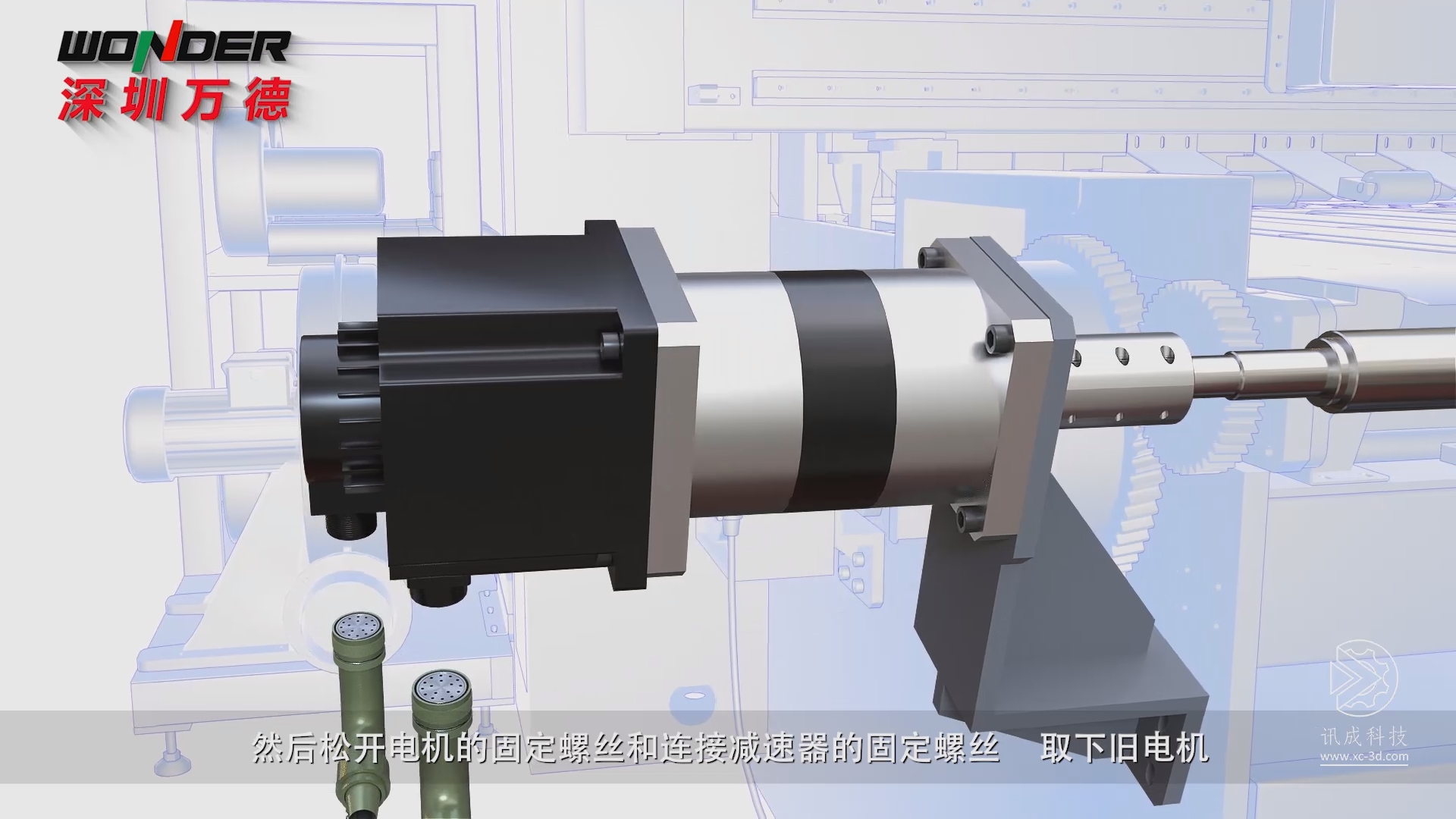

Smart Training: Creating an Immersive Skill Inheritance Platform

Talent development is a crucial pillar of the smart O&M system. The immersive learning environment created by 3D animation is reshaping the training model for industrial maintenance. After introducing the 3D animation training system, Shenzhen Wander Digital Technology Co., Ltd. achieved a digital transformation in the transmission of maintenance skills. The system supports multi-language switching and fault scenario simulation, enabling trainees to complete the entire process from basic understanding to complex troubleshooting in a virtual environment. This innovative model successfully reduced the training cycle by 40% while significantly lowering the practical error rate.

Data Visualization: Building a Cognitive Bridge for O&M Decisions

In the smart O&M system, 3D animation serves as a cognitive bridge connecting the world of data and the physical world. By dynamically linking equipment operating parameters, fault warning information with 3D models, maintenance personnel can intuitively understand the equipment status behind the data. This deep integration of data and visualization provides more intuitive decision support for predictive maintenance and is becoming an important direction for technological evolution in the industry.

From standardized operations to systematic cognition, from digital training to intelligent decision-making, 3D animation is building a complete visualized practical system for smart O&M in the field of industrial maintenance. This technology not only addresses current O&M pain points but also opens up new paths for the digital transformation of future industries. With the deep integration of technologies like 5G and digital twins, 3D animation will undoubtedly paint a more brilliant chapter in the broad landscape of industrial smart O&M.

FAQ Highlights:

Q: What areas does Xuncheng Animation Video Production cover?

A: Animation video production includes the following three categories:

Promotional: Including product promotion, corporate promotion, etc.

Technical: Including equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, equipment safety, etc.

Custom: Including exhibition videos, investment promotion videos, event warm-up videos, etc.

Q: How to produce 3D animation related to equipment maintenance?

A: Most mechanical and production factories rely on experienced and qualified mechatronic engineers for equipment maintenance. Equipment maintenance animation can effectively solve this problem.

1. It is recommended to first produce animations for common equipment failure points (including mechanical and electrical);

2. Record and document on-site maintenance to accumulate material for animation production;

3. Quantity: It is recommended to produce about 10-15 mechanical maintenance and 5-8 electrical maintenance animations for large equipment initially; for medium and small equipment, about 6-8 mechanical maintenance and 3-5 electrical maintenance animations;

4. Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project contact personnel should be relatively stable.

Q: Are equipment usage animations very expensive?

A: Conclusion first: Equipment usage animations create benefits for machinery factories. The greater the investment, the greater the return.

The production cost of equipment usage animations generally ranges from tens of thousands to hundreds of thousands of yuan, or even higher. While seemingly expensive, the average cost per equipment is not high.

How do equipment usage animations create benefits for machinery factories?

1. Low average cost. Machinery equipment is generally updated slightly every 2 years and significantly every 4 years, so the total cost of animation video production is very low when averaged per unit;

2. Equipment premium. According to actual test data from machinery factories, for every yuan invested in producing equipment operation and maintenance animations, the equipment sales premium generated is about 3-5 yuan (i.e., 3-5 times);

3. Significantly reduce after-sales service costs, especially during the equipment warranty period;

4. Effectively increase customer loyalty;

5. More competitive compared to similar products.

Characteristics: High initial investment, very low subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients include startups, overseas clients, listed companies, foreign-funded enterprises, and other diverse types of businesses. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether it's at an exhibition or during a client visit, whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with breathtaking 3D animation. This not only brings a unique visual experience to clients but also quickly resonates with them.