In the modern industrial manufacturing environment, the standardization of equipment operation directly affects production efficiency, product quality, and safety production. Traditional operation training mainly relies on paper manuals and master-apprentice methods, which often suffer from understanding deviations, inconsistent standards, and long training cycles. The application of 3D industrial animation technology is providing innovative solutions for enterprises to enhance equipment operation standardization.

Establish Unified Visual Operation Standards

The primary challenge in equipment operation standardization lies in establishing unified and clear operation standards. Through precise equipment modeling and process demonstration, 3D industrial animation transforms abstract textual procedures into intuitive visual standards. Unlike the limitations of traditional 2D drawings, 3D animation can showcase operational details from the optimal perspective, ensuring that every operator gains a completely consistent understanding of the standards.

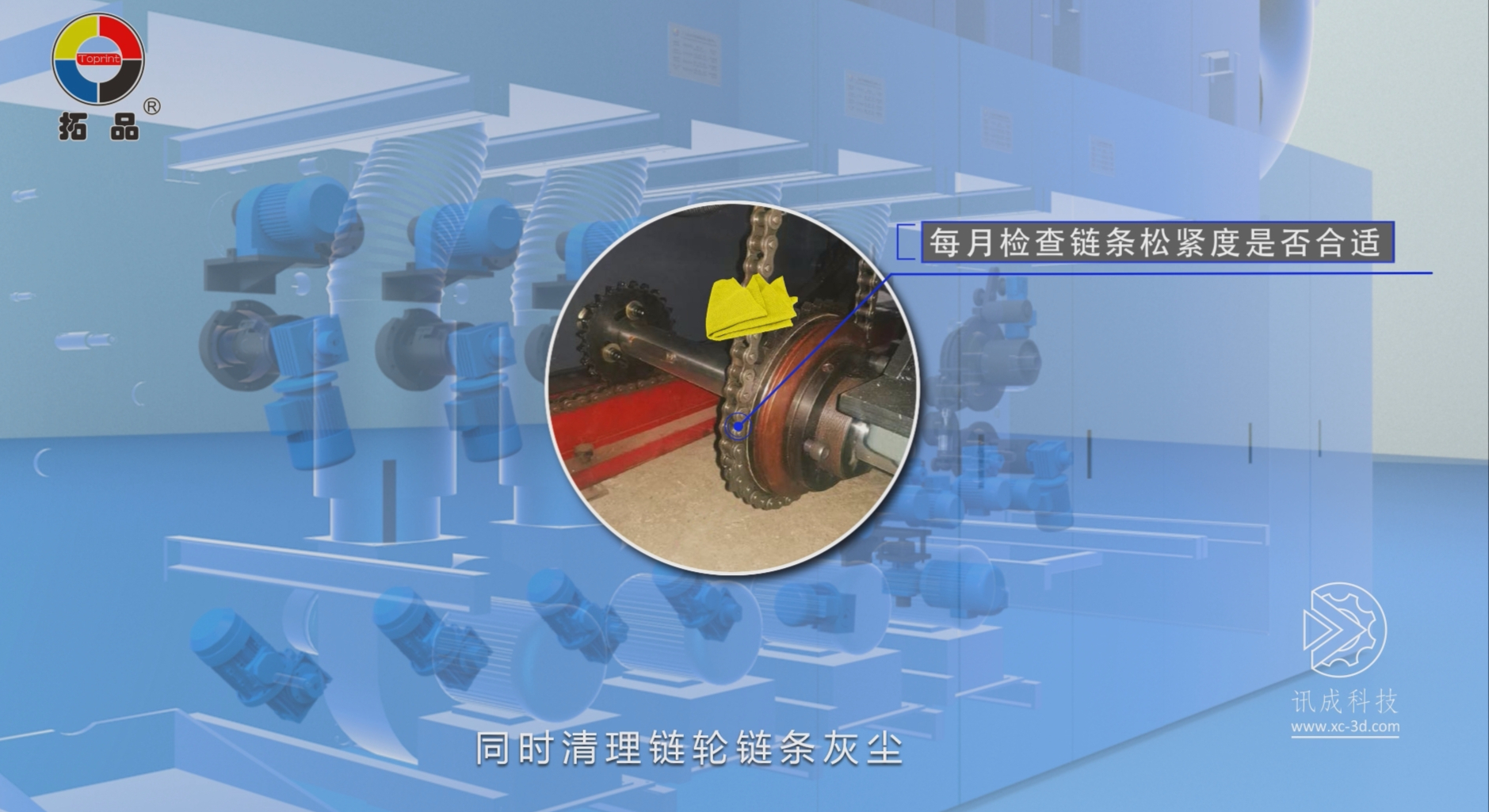

In practical applications, the establishment of such visual standards significantly lowers the barrier to understanding. Operators no longer need to rely on personal experience to imagine the operation process but receive precise operational guidance through animation demonstrations. The ink printing press operation animation by Guangdong Tuopin Intelligent Machinery Technology Co., Ltd. breaks down complex equipment operation processes into clear step-by-step demonstrations, enabling new employees to master standard operating methods in a shorter period.

Strengthen Grasp of Key Operational Details

Many key details in equipment operation are often difficult to describe accurately in words, yet these details are precisely important factors affecting operational standardization. Through techniques such as slow-motion playback, close-ups, and perspective displays, 3D industrial animation emphasizes key operational nodes, ensuring operators can accurately grasp the essentials of each action.

Taking precision equipment operation as an example, animation can clearly show pre-start inspection points, key monitoring aspects during operation, and post-shutdown maintenance requirements. Practices at Shenzhen Wande Digital Technology Co., Ltd. show that after operation training using 3D animation, employees' accuracy in grasping key operational points has significantly improved, and the rate of overlooking details during operation has markedly decreased.

Achieve Standardized Execution of Operation Processes

The core of equipment operation standardization lies in ensuring that every operator can perform tasks according to unified standards. Through standardized visual language, 3D industrial animation establishes a reproducible and promotable system of operational norms. This standardization is reflected not only in the uniformity of operation steps but also in deeper requirements such as operating rhythm, force control, and safety checks.

In practical promotion, 3D animation can ensure that operators from different teams and shifts execute the same operational standards. This consistency not only improves production efficiency but also ensures the stability of product quality. By repeatedly watching animation demonstrations, operators can continuously optimize their operating methods and form standardized operating habits.

Enhance Training Effectiveness and Knowledge Transfer

Traditional operation training often depends on the trainer's individual skill level, making training effectiveness difficult to guarantee. 3D industrial animation, through standardized training content, ensures that every employee receives the same quality of training. The flexographic printing press operation animation produced for Xiamen Sanlei Packaging Materials Co., Ltd. reduced new employee training time by 40% while significantly improving training quality.

More importantly, 3D animation achieves effective transfer of operational knowledge. The experience and skills of senior operators can be preserved in the form of animation, creating valuable intellectual assets for the enterprise. This method of knowledge transfer not only prevents knowledge loss due to staff turnover but also provides a foundation for continuous improvement.

Promote the Cultivation of Safe Operation Awareness

Safe operation is an important component of equipment operation standardization. 3D industrial animation can intuitively demonstrate the consequences of unsafe operations, enhancing operators' safety awareness through visual impact. Animation can simulate the potential outcomes of various non-compliant operations, making operators deeply understand the importance of adhering to norms.

In practical applications, this safety education method is more effective than traditional written warnings. Through animation demonstrations, operators can clearly recognize the safety risks at each operational step, thus paying more attention to operational standards in their work. This enhancement of safety awareness provides strong support for the enterprise's safe production.

Establish a Virtuous Cycle of Continuous Improvement

3D industrial animation also provides technical support for the continuous improvement of equipment operation standards. By collecting feedback information during the operation process, enterprises can continuously optimize animation content to better meet actual needs. This continuous improvement mechanism ensures that operational standards always remain in an optimal state.

Concurrently, an animation-based assessment system can objectively evaluate operators' skill levels, providing a basis for improving training content. Operators can also engage in self-directed learning through animation, promptly identifying and correcting their shortcomings, thus forming a virtuous learning cycle.

Through multiple dimensions such as establishing visual standards, strengthening operational details, and standardized execution, 3D industrial animation comprehensively enhances enterprise equipment operation standardization. This technological application not only solves the pain points of traditional training methods but also establishes a system of continuously improvable operational standards for enterprises. With the continuous advancement of technology, 3D industrial animation will play an increasingly important role in the field of equipment operation standardization management, assisting enterprises in achieving high-quality development.

Featured FAQs:

Q: What benefits do equipment operation and maintenance animations bring to machinery factories?

A: Paper operation manuals are outdated.

Equipment operation and maintenance animations are divided into six major categories: Equipment Operation, Equipment Maintenance, Equipment Repair, Wearable Part Replacement, Equipment Assembly, Equipment Safety

Benefits of demonstrating equipment operation and maintenance with animation:

1-Provide more professional after-sales support for customers. Equipment operation animations can quickly train new staff; equipment maintenance animations make maintenance more standardized, keeping equipment in peak condition; equipment repair animations allow customers to resolve common minor faults themselves, effectively increasing equipment uptime; wearable part replacement allows customers to flexibly schedule replacements based on production needs; equipment assembly animations can significantly reduce reliance on experienced installation personnel; equipment safety animations can provide customers with professional safety guidance and training materials.

2-Effectively enhance customer loyalty. Practice shows that customers greatly appreciate using animation demonstrations to solve various problems during equipment use, making animation highly effective in strengthening customer loyalty.

3-Significantly reduce after-sales service pressure, especially for warranty services (some customers have calculated that it can reduce unnecessary after-sales services by at least 30%-40%), the effect is more pronounced with larger equipment output.

4-Become a sales tool. Equipment manufacturers that have produced operation and maintenance animations present a new concept to customers during marketing: worry-free equipment usage.

5-Reduce training costs, decrease equipment maintenance costs, and improve production efficiency.

6-Enhance brand image and market competitiveness, facilitating technology dissemination.

Q: How to produce 3D animations related to equipment repair?

A: Most machinery and production factories rely on experienced and qualified mechatronic engineers for equipment repair. Equipment repair animations can effectively address this issue.

1-It is recommended to first produce repair animations for common equipment failure points (including mechanical and electrical).

2-Record and document on-site repairs to accumulate material for animation production.

3-Quantity: For large equipment, it is recommended to produce around 10-15 mechanical repairs and 5-8 electrical repairs initially; for medium and small equipment, around 6-8 mechanical repairs and 3-5 electrical repairs.

4-Equipment repair animation is a process of continuous accumulation and optimization, with a relatively long production cycle, requiring relatively stable project liaison personnel.

Q: Are operation and maintenance animations very expensive?

A: To conclude first: Equipment operation and maintenance animations create value for machinery factories. The greater the investment, the greater the return.

The production cost of equipment operation and maintenance animations typically ranges from tens of thousands to hundreds of thousands of yuan, or even higher. While seemingly expensive on the surface, the average cost per piece of equipment is not high.

How do equipment operation and maintenance animations create value for machinery factories?

1-Low amortized cost. Machinery and equipment typically undergo minor modifications every 2 years and major upgrades every 4 years; the total cost of animation video production is very low when amortized across each machine unit.

2-Equipment premium. According to actual measurements from machinery factories, for every yuan invested in producing operation and maintenance animations, the equipment sales premium generated is about 3-5 yuan, a 3-5 fold return.

3-Significantly reduce after-sales service costs, especially during the equipment warranty period.

4-Effectively increase customer loyalty.

5-More competitive compared to similar products.

Characteristic: Significant upfront investment, minimal subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. Specializing in providing 3D animation creation for mechanical equipment, high-tech, software development, foreign trade companies, etc. Offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with stunning 3D animation. This not only brings a unique visual experience to clients but also quickly impresses them.