In the field of industrial manufacturing, after-sales service is undergoing a profound transformation from a cost center to a value creation center. Traditional after-sales models face pain points such as slow response times, high service costs, and difficulties in knowledge transfer. The application of 3D animation technology provides a novel approach to solve these problems. This technology not only changes the way services are delivered but also redefines the value connotation of after-sales service.

Visual Guidance Reshapes Service Processes

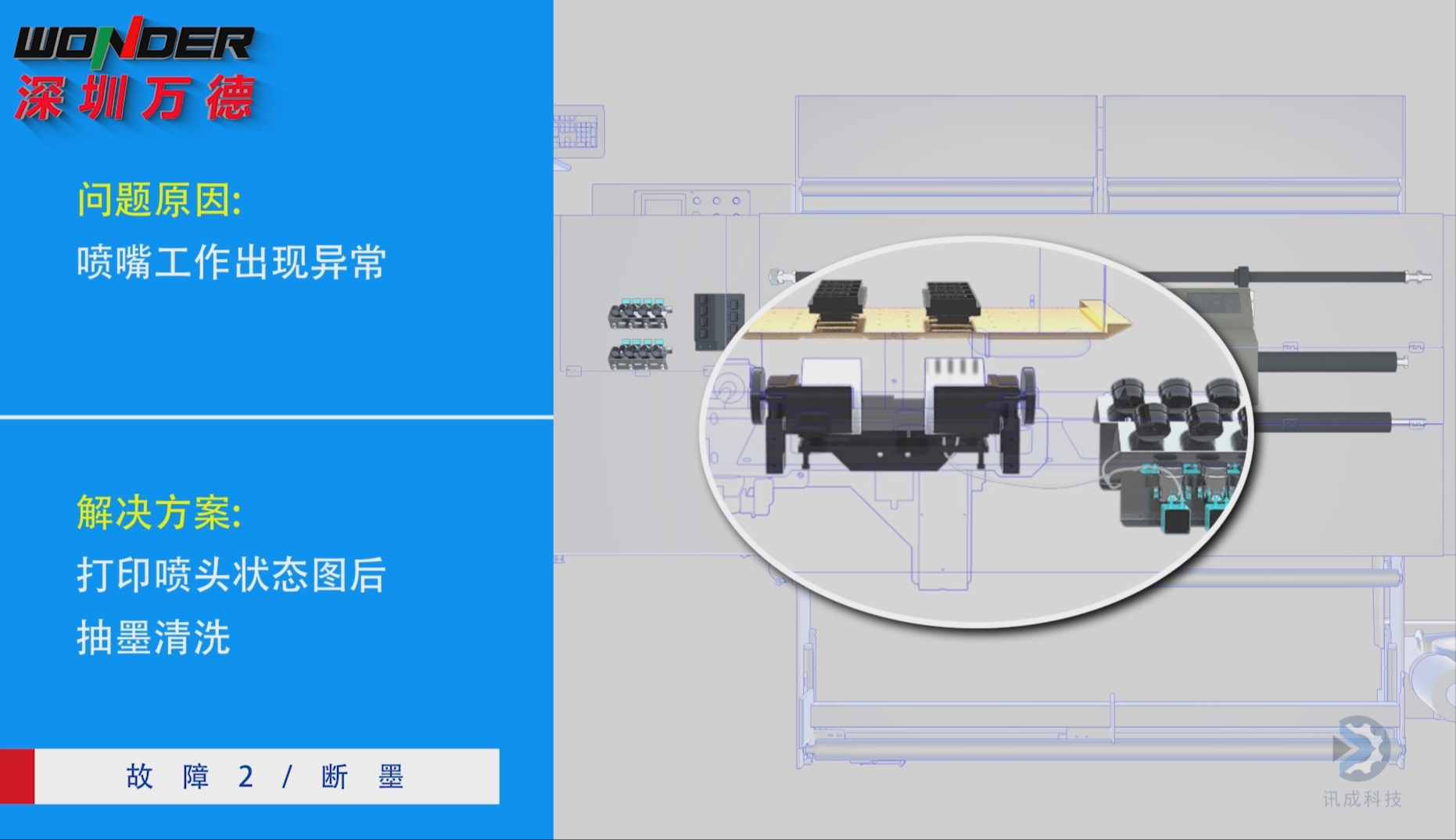

3D animation technology, through precise visual representation, has completely changed the execution methods of traditional industrial after-sales service. In equipment maintenance, technicians often need to rely on experience to diagnose the cause of faults, a process that is both time-consuming and prone to errors. 3D animation visually demonstrates the internal structure and working principles of equipment, enabling technicians to quickly pinpoint the problem.

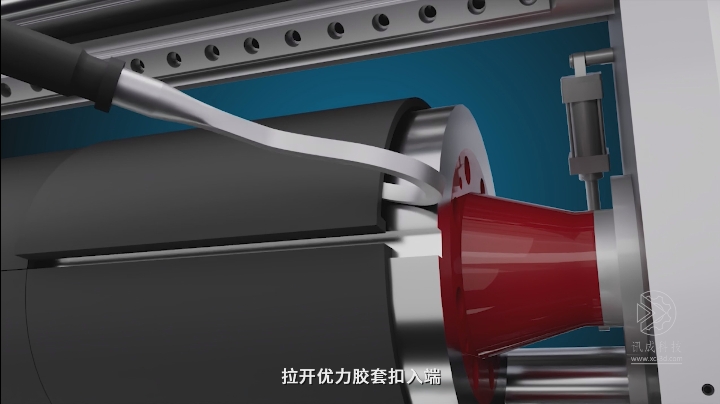

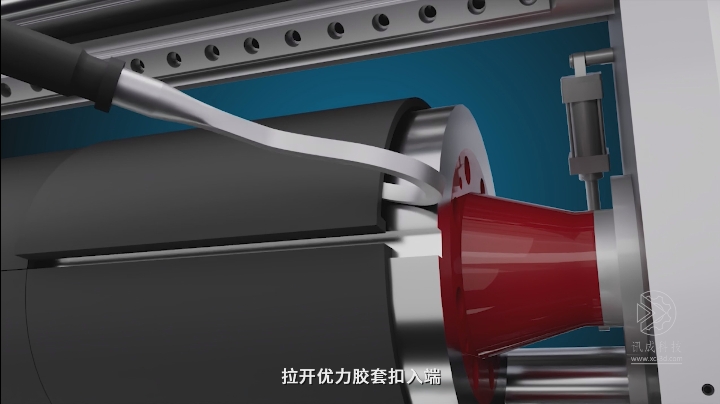

The practice of Shenzhen Wander Digital Technology Co., Ltd. fully demonstrates this value. The company uses 3D animation to showcase the internal structure and workflow of digital printing machines, allowing technicians to gain a comprehensive understanding of the equipment before maintenance. This visual guidance not only improves repair efficiency but also significantly reduces the risk of operational errors. More importantly, this service method breaks the traditional over-reliance on expert experience in maintenance, making standardized, high-quality service possible.

Innovative Model for Knowledge Transfer

The field of industrial after-sales service has long faced the challenge of knowledge transfer. The valuable experience accumulated by senior technicians is often difficult to effectively pass on, while training new personnel requires a long period. 3D animation technology innovatively solves this problem by transforming tacit knowledge into explicit content.

The maintenance animation for ink printing machines by Guangdong Topin Intelligent Machinery Technology Co., Ltd. not only demonstrates standard operating procedures but also helps technicians deeply understand the equipment's operating mechanisms through transparent structures and dynamic demonstrations. This in-depth knowledge transfer enables technicians to make more accurate judgments and handle new issues. The innovation in knowledge transfer models not only accelerates talent development but also accumulates valuable knowledge assets for the company.

Fundamental Change in Service Models

The application of 3D animation technology is driving a fundamental change in industrial after-sales service models. The traditional passive service model of 'fault occurs - on-site repair' is transforming into a proactive service model of 'preventive maintenance - predictive service.' The core of this shift is that 3D animation makes the transfer of equipment knowledge no longer restricted by time and space, allowing customers to access the technical support they need anytime, anywhere.

The case of Foshan Jinbing Machinery Co., Ltd. showcases the value of this transformation. Through a preventive maintenance system built with 3D animation, customers can identify potential equipment issues in advance, effectively avoiding production losses caused by sudden failures. This change in service model not only enhances customer satisfaction but also redefines the relationship between manufacturing enterprises and their customers.

Efficiency Breakthroughs in Remote Collaboration

In a globalized context, after-sales service for industrial equipment often requires cross-regional support. 3D animation technology, by enabling remote visual guidance, effectively addresses the issue of uneven distribution of expert resources. On-site technicians can retrieve relevant animations via mobile devices, while remote experts can provide precise technical guidance through annotations and real-time communication.

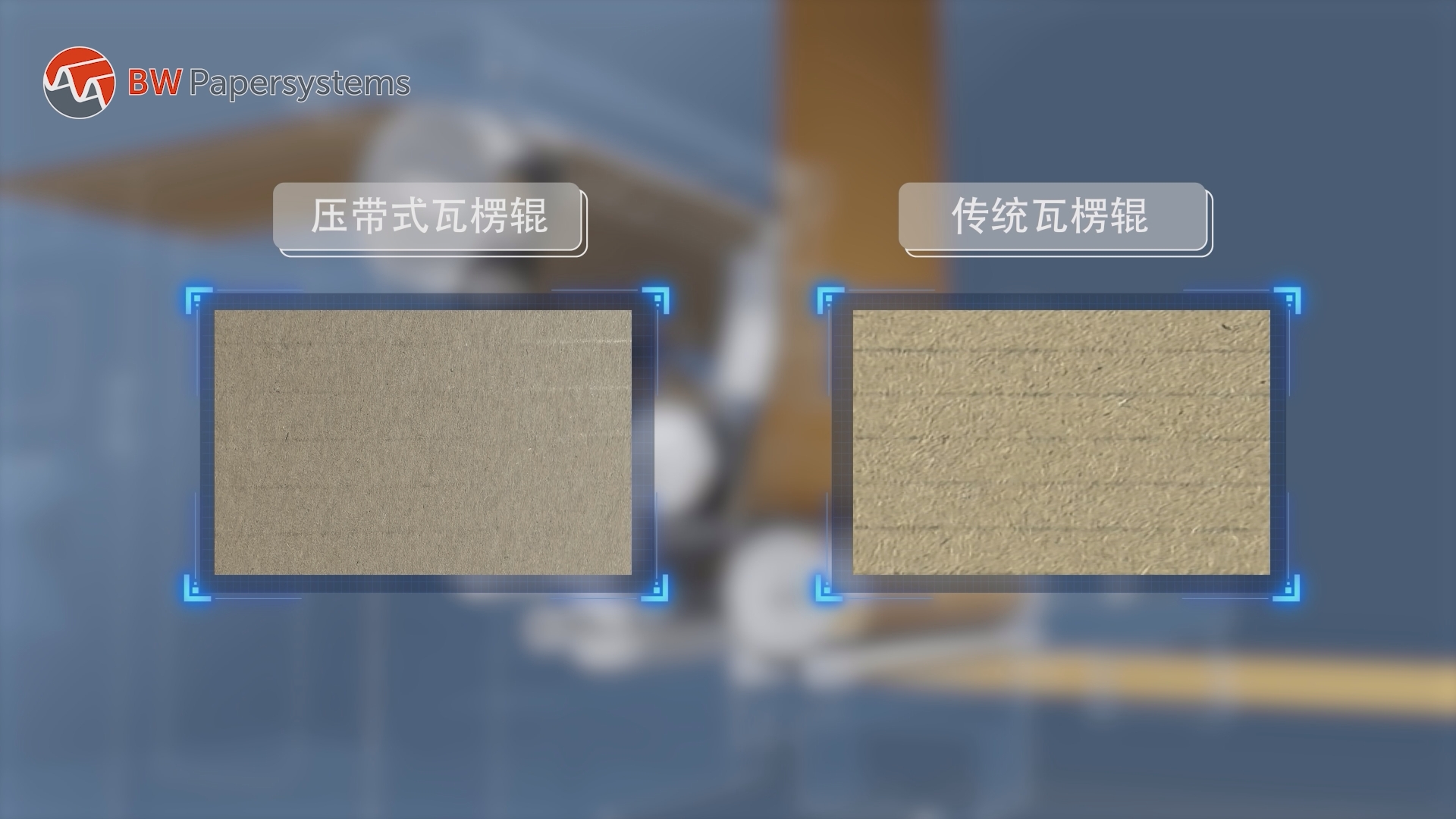

This remote collaboration model has achieved significant results in the practice of American company Marquip. Through remote support using 3D animation, the company has not only greatly improved service response speed but also maximized the utilization of expert resources. The efficiency breakthrough in remote collaboration allows high-quality technical services to transcend geographical limitations, creating greater value for customers.

Diverse Paths to Value Creation

The application of 3D animation in industrial after-sales service is opening up diverse paths for value creation. Beyond direct improvements in service efficiency, this technology brings about deeper value innovation. The promotion of standardized services reduces fluctuations in service quality, the accumulation of knowledge assets enhances core corporate competitiveness, and the implementation of preventive maintenance creates new customer value.

Notably, these value innovations are reshaping corporate profit models. Traditional after-sales services are often viewed as cost centers, whereas new service models based on 3D animation exhibit characteristics of profit centers. The development of value-added services, enhanced customer loyalty, and increased brand value are all creating sustainable competitive advantages for enterprises.

Future Outlook for Intelligent Development

With the rapid development of digital technologies, the application of 3D animation in industrial after-sales service is evolving to higher levels. The maturity of digital twin technology will enable real-time interaction between virtual models and physical equipment; the application of augmented reality technology will make on-site services more precise and efficient; the development of artificial intelligence will drive more intelligent service decision-making.

The integration and innovation of these technologies will propel industrial after-sales service towards intelligence and personalization. Future after-sales services will no longer be simple problem-solving but will become precise services based on data-driven and intelligent analysis. This transformation will not only further enhance service efficiency but also usher in a new paradigm for industrial after-sales service.

Continuous Release of Innovative Value

The application of 3D animation technology in industrial after-sales service demonstrates continuous innovative value. From initial operational guidance to current intelligent services, the value connotation of this technology is constantly being enriched and deepened. As application scenarios continue to expand and the technology itself keeps advancing, its innovative value will be further unleashed.

For manufacturing enterprises, grasping this technological trend and accelerating the pace of digital transformation will be key to winning future market competition. 3D animation is not just a technological tool; it is a significant driving force for service innovation and value reconstruction. In this process of change, enterprises that dare to innovate and are adept at learning will gain greater development space.

Featured FAQs:

Q: What segments does Xuncheng's animation video production cover?

A: Animation video production includes the following three categories:

Promotional: Includes product promotion, corporate promotion, etc.

Technical: Includes equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, equipment safety, etc.

Custom: Includes videos for exhibitions, investment promotion, gala warm-ups, etc.

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to feed paper; the printing unit mainly explains how to apply ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machine manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always remains with the machine manufacturer.

Q: How can small companies without an 'Equipment Operation Manual' produce operation and maintenance animations?

A: Xuncheng can provide full-chain equipment operation and maintenance animation production services. Specifically:

1- After the equipment is installed and debugged, the machine manufacturer can record on-site training sessions with multiple fixed cameras and convert them into documents (Xuncheng can also provide this service);

2- Xuncheng categorizes and optimizes the relevant content;

3- The document is sent to the machine manufacturer for confirmation;

4- Animation is produced.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises, including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services, covering from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at trade shows or during client visits, whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with stunning 3D animations. This not only brings a unique visual experience to clients but also quickly touches their hearts.