In the field of modern industrial equipment maintenance, maintenance efficiency and quality directly affect the stable operation of production lines. Traditional equipment maintenance relies on paper manuals and engineer experience, facing pain points such as low information transmission efficiency, inconsistent operating standards, and long training cycles for new staff. Industrial animation technology, with its unique visual advantages, is bringing revolutionary changes to industrial mechanical equipment maintenance.

Visualization Guidance for the Maintenance Process

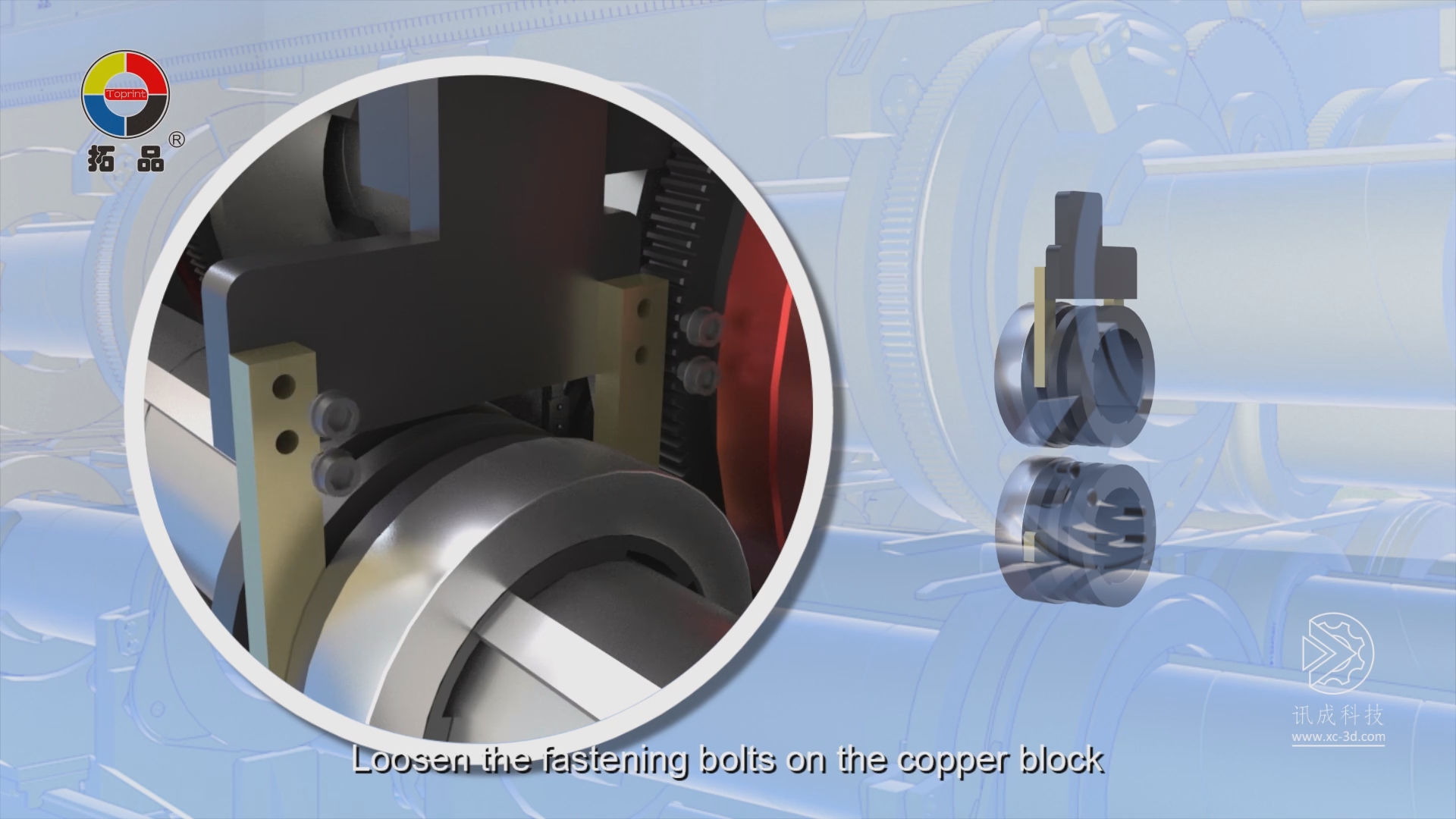

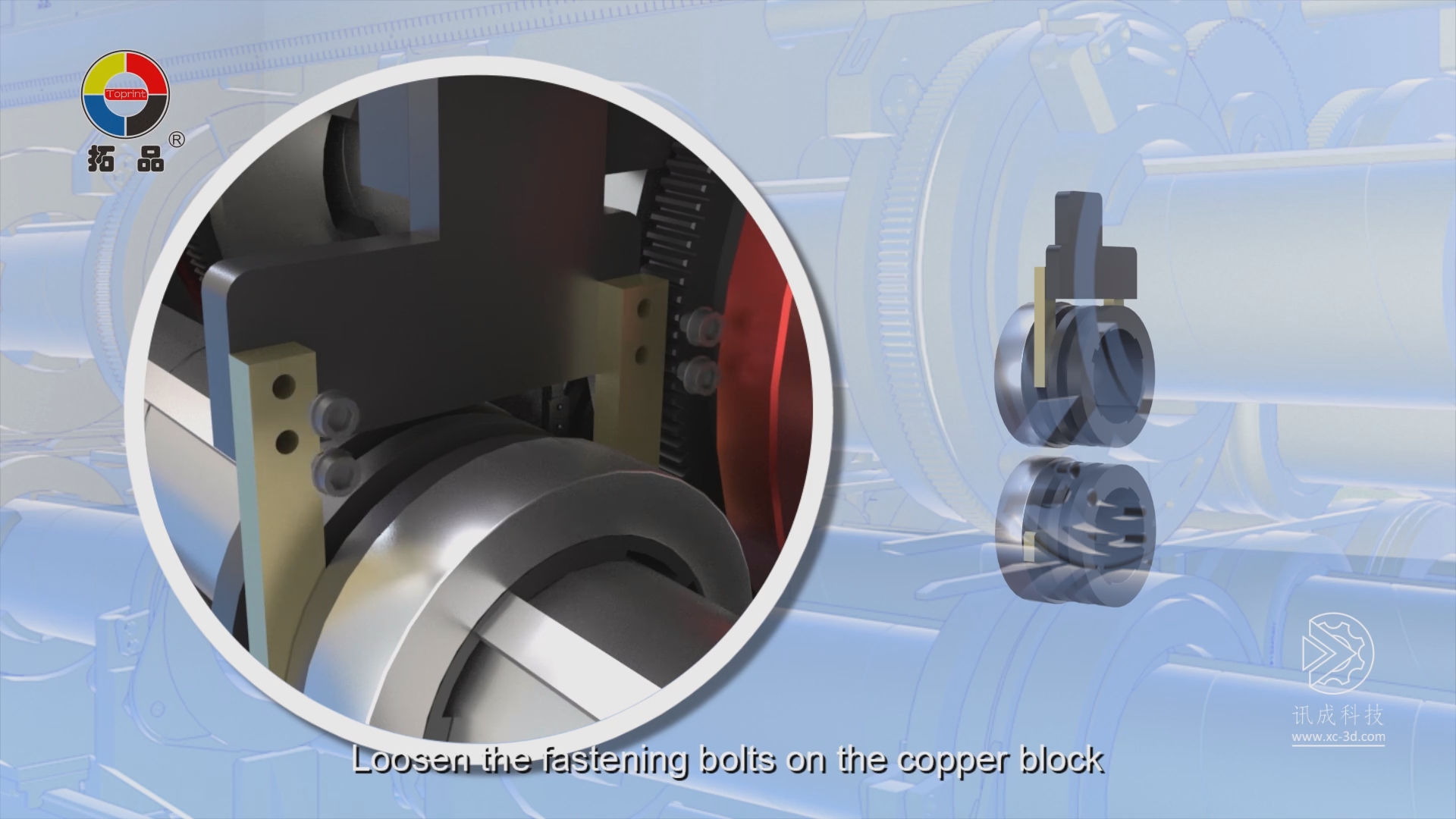

When large industrial equipment malfunctions, traditional maintenance guidance often relies on two-dimensional drawings and textual descriptions. Maintenance personnel need to construct a three-dimensional model in their minds, a process that is both time-consuming and prone to errors. Industrial animation, through precise equipment modeling and dynamic demonstrations, transforms complex maintenance procedures into intuitive visual guidance.

In the practice of Guangdong Toprint Intelligent Machinery Technology Co., Ltd., maintenance animations for ink printing machines vividly demonstrate the entire process from fault diagnosis to component replacement. The animations utilize multi-angle shots and perspective techniques to clearly present the internal structure of the equipment, enabling maintenance personnel to accurately understand the sequence of each disassembly step and the key operational points. This visual guidance has reduced average maintenance time by 40% and achieved a maintenance quality consistency of over 95%.

Standardized Inheritance of Maintenance Knowledge

In traditional maintenance models, the experience of senior engineers is often difficult to effectively pass down. Industrial animation establishes a systematic knowledge management system by transforming best maintenance practices into standardized visual content. This innovative approach not only accelerates the training of new personnel but also ensures the stability of maintenance quality.

The maintenance animation system developed by Shenzhen Wonder Digital Technology Co., Ltd. for its digital printing machines includes solutions for dozens of common faults. New employees can master core maintenance skills in a shorter period through animation learning. Company data shows that after adopting animation training, the time for new employees to work independently was reduced by 50%, and the maintenance error rate decreased by 60%. More importantly, this system supports multiple language versions, effectively solving the maintenance training challenges for multinational corporations.

Collaborative Innovation in Remote Maintenance

In the context of global manufacturing, equipment maintenance often requires cross-regional collaboration. The integration of industrial animation with remote communication technology provides innovative solutions for remote maintenance. When field technicians encounter complex faults, they can receive precise guidance from remote experts through the animation system.

The case of Ruichang Jinggong Enterprise demonstrates the significant benefits of this model. The company has established a remote support system for its equipment based on industrial animation. When equipment malfunctions, on-site personnel retrieve the corresponding fault-handling animations, and remote experts provide technical guidance through real-time annotations. This collaborative model has enabled remote resolution for 65% of faults, reducing the average response time from 72 hours to 4 hours, thereby significantly lowering service costs.

Building a System for Preventive Maintenance

Industrial animation also plays an important role in promoting preventive maintenance. By demonstrating the operating principles and wear patterns of equipment, the animation system helps maintenance personnel establish a scientific equipment maintenance system, reducing equipment failure rates from the source.

The practice of Foshan Jinbing Machinery Co., Ltd. shows that the animation-based preventive maintenance system has reduced the rate of sudden equipment failures by 45%. The animations clearly illustrate the lifespan cycles and replacement standards of critical components, guiding maintenance personnel to accurately grasp the timing of maintenance. This forward-looking maintenance model not only improves equipment reliability but also achieves reasonable control over maintenance costs by optimizing the maintenance cycle.

Mining the Value of Maintenance Data

The industrial animation system can also record and analyze various data during the maintenance process, providing a basis for continuous improvement. By analyzing the usage data of maintenance animations, companies can identify common fault types, optimize spare parts inventory, and improve product design.

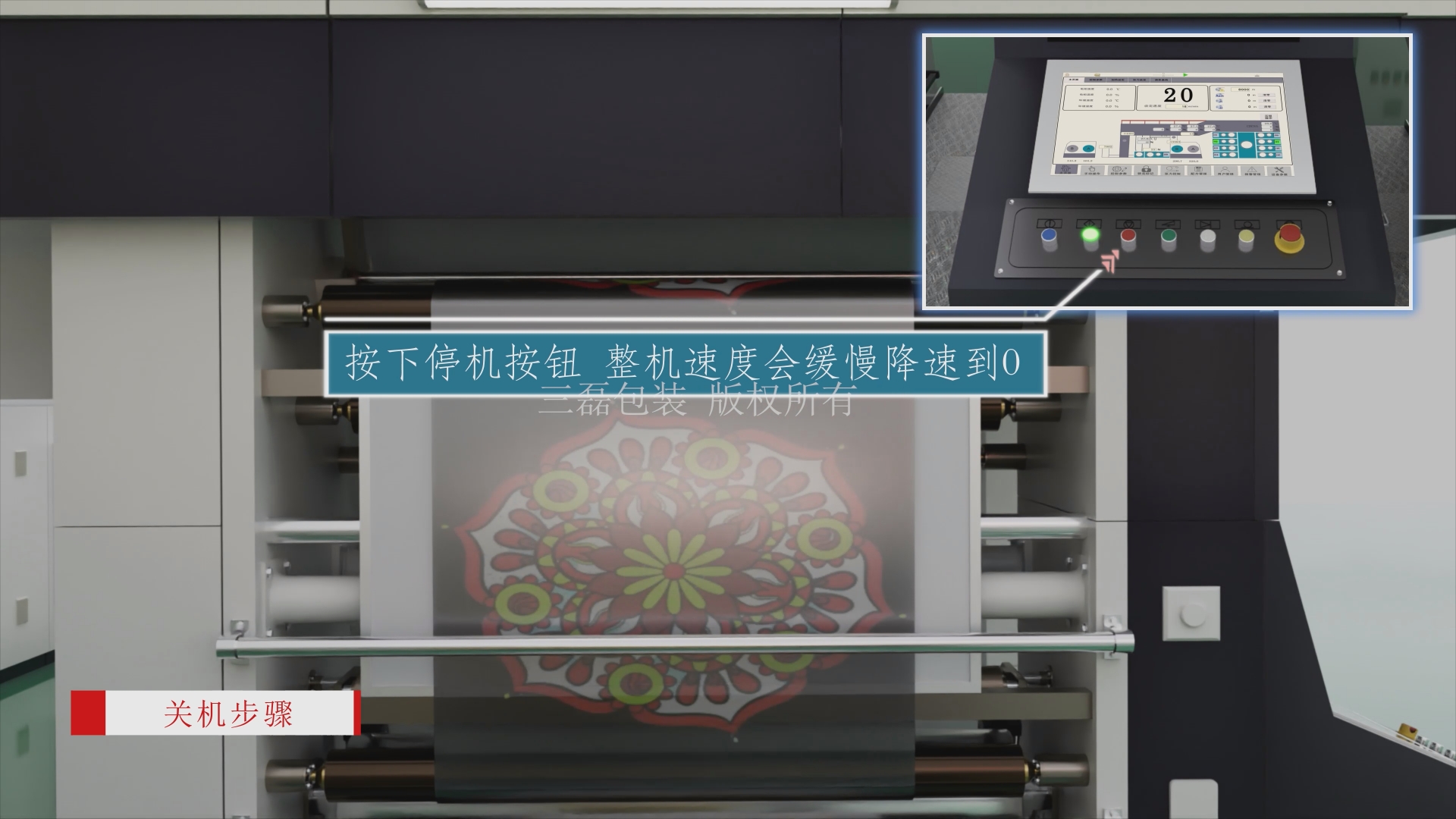

Xiamen Sanlei Packaging Material Co., Ltd., by analyzing the usage data of its maintenance animation system, identified common fault points across multiple equipment models and subsequently optimized equipment design improvements. This data-driven improvement mechanism led to a 30% increase in equipment reliability and significantly improved customer satisfaction within six months.

Intelligent Evolution for Future Development

With technological advancements, the application of industrial animation in equipment maintenance is evolving towards intelligence. The introduction of augmented reality technology allows maintenance guidance information to be directly overlaid onto real equipment; the application of artificial intelligence enables intelligent fault diagnosis and automatic generation of maintenance plans; digital twin technology facilitates real-time interaction between virtual models and physical equipment.

The integrated development of these technologies will further enhance the application value of industrial animation in equipment maintenance. Future equipment maintenance will be more precise, efficient, and intelligent, providing stronger assurance for the stable operation of manufacturing.

In summary, industrial animation technology is profoundly changing the maintenance models for industrial mechanical equipment. From visual guidance to knowledge inheritance, from remote collaboration to preventive maintenance, its application value has been validated across multiple dimensions. With continuous technological progress, industrial animation will undoubtedly play an even more important role in the field of equipment maintenance, driving manufacturing towards a more intelligent and efficient future.

Featured FAQs:

Q: What preparations are needed for creating 3D animations for equipment maintenance?

A: Most mechanical and production plants primarily rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animations can effectively solve this problem.

1-It is recommended to first create maintenance animations for common equipment fault points (including mechanical and electrical);

2-Record and document on-site maintenance to accumulate material for animation production;

3-Quantity: It is recommended to produce about 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment initially; for medium and small equipment, about 6-8 mechanical maintenance animations and 3-5 electrical maintenance animations;

4-Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project liaison personnel should be relatively stable.

Q: What categories does Xuncheng Animation Video Production include?

A: Animation video production includes the following three categories:

Promotional: Including product promotion, corporate promotion, etc.

Technical: Including equipment operation, equipment maintenance, equipment repair, wearable parts replacement, equipment assembly, equipment safety, etc.

Customized: Including exhibition videos, investment promotion videos, banquet warm-up videos, etc.

Q: Are equipment usage animations very expensive?

A: Conclusion first: Equipment usage animations create benefits for machinery factories. The greater the investment, the greater the return.

The production cost of equipment usage animations generally ranges from tens of thousands to hundreds of thousands, or even higher. While seemingly expensive, the actual average cost per piece of equipment is not high.

How do equipment usage animations create benefits for machinery factories?

1-Low amortized cost. Machinery and equipment are generally modified slightly every 2 years and significantly every 4 years. The total cost of animation video production is very low when amortized across each machine;

2-Equipment premium. According to actual test data from machinery factories, for every 1 yuan invested in creating equipment operation and maintenance animations, the resulting equipment sales premium is about 3-5 yuan, i.e., 3-5 times);

3-Significantly reduces after-sales service costs, especially during the equipment warranty period;

4-Effectively improves customer loyalty;

5-More competitive compared to similar products.

Characteristics: Significant initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients including startups, overseas clients, listed companies, and foreign-owned enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits, whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with stunning 3D animations. This not only brings a unique visual experience to clients but also quickly resonates with their needs.