In the delivery and operation of industrial equipment, the efficiency of the installation and commissioning phase directly affects project cycles and costs. Traditional installation manuals rely on text, two-dimensional drawings, or on-site guidance, which can lead to issues such as unclear information transfer and operational understanding discrepancies. Equipment installation animations, through 3D visualization technology, transform complex installation processes into dynamic imagery, providing project teams with intuitive and accurate construction guidance, becoming a digital solution to accelerate project implementation.

I. Technical Characteristics and Alignment with Project Implementation Needs

Equipment installation animations use equipment CAD drawings as data sources, achieving component-level dimension restoration through parametric modeling technology. The equipment installation process is broken down into multiple detailed steps and demonstrated one by one in the animation. Each step is accompanied by text descriptions and voice prompts, ensuring installers accurately grasp operational key points. This makes the animation content possess both engineering rigor and construction guidance value.

II. Core Application Scenarios and Implementation Value

(I) Pre-construction Training: Standardized Operation Demonstration

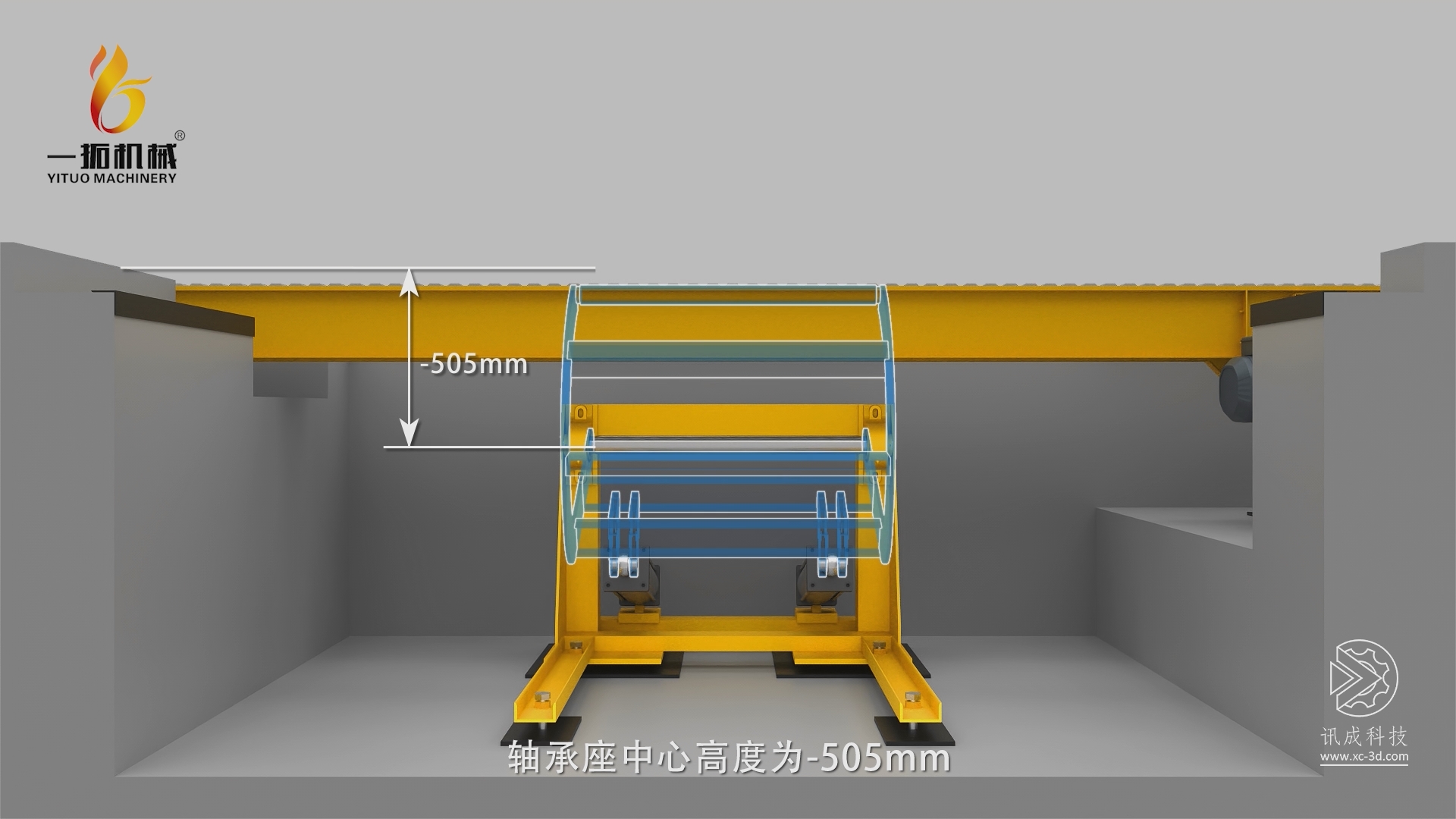

In the corrugated board production line installation animation produced by Xiamen Xuncheng for Shanghai Yituo Papermaking Machinery Co., Ltd., the installation sequence and positioning methods from foundation treatment, paper unwinder platform installation to the placement of chain conveyors are clearly demonstrated. Construction personnel can quickly grasp the installation process by watching the animation, avoiding rework due to improper operation and thus shortening installation time.

(II) On-site Guidance: Visualized Operation Manual

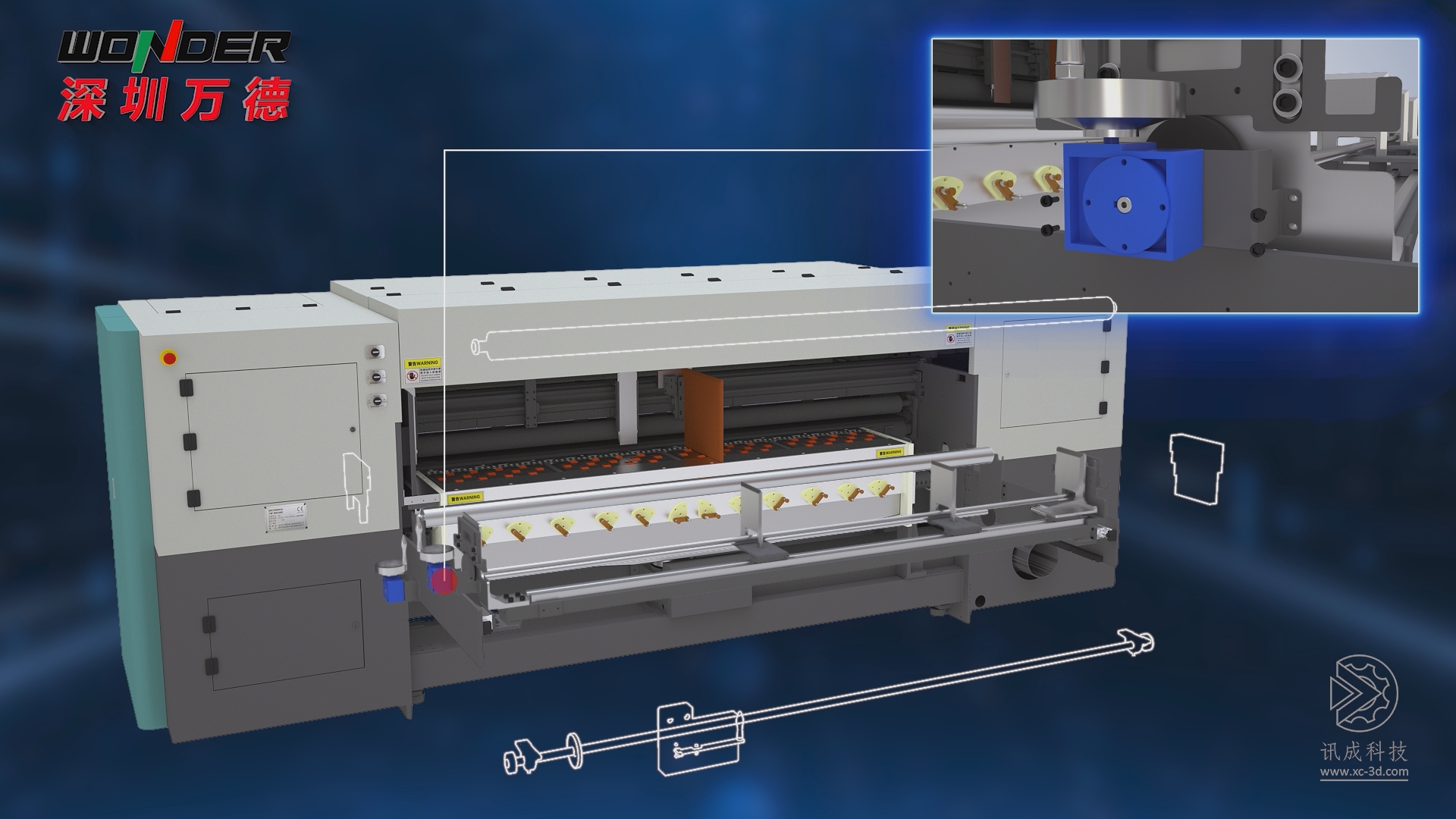

In scenarios where equipment is widely distributed or technology is frequently updated, 3D industrial animations become 'digital mentors' for construction personnel. For example, after Xiamen Xuncheng produced a digital printing press installation animation for Wandu Digital's after-sales service team, it not only allowed new employees to repeatedly watch and understand key installation points and precautions but also provided early warnings and solutions for installation issues to the client's factory, enabling the client's staff to prepare in advance, shorten training cycles, and improve their operational skills and safety awareness.

(III) Multi-channel Collaboration: Virtual Pre-assembly and Content Planning

For multinational projects, equipment installation animations can support multi-language subtitles, voiceovers, and interfaces, eliminating language barriers. This helps installers prepare in advance and resolve issues quickly. During the pandemic, Guangdong Zhaoqing Xijiang Machinery Manufacturing Co., Ltd. commissioned Xiamen Xuncheng to produce equipment installation animations. Through animated demonstrations and remote guidance for the manufacturing enterprise to assemble the machinery themselves, it resolved the awkward situation of engineers being unable to travel for equipment installation.

III. Industry Trends and Innovation Directions

With the rapid development of the Industrial Internet of Things, installation animations are upgrading from static demonstration tools to dynamic optimization platforms. In the future installation and construction phases, 3D animations will combine with Augmented Reality (AR) technology to create an immersive experience of real-time guidance. High-quality equipment installation animations must follow a four-stage process: 'Modeling - Simulation - Verification - Delivery'. Such control processes enable animation technology to reduce installation and construction error rates, ensuring project implementation safety and efficiency.

Equipment installation animations, by integrating technical visualization with engineering simulation, are reshaping the technical ecosystem of project implementation. Their high-precision modeling, dynamic simulation, and AR interaction capabilities make animations a core link connecting design, construction, and acceptance. With the deepening application of Digital Twin and Industrial Metaverse technologies in the future, installation animations will play a more critical role in project lifecycle management, assisting the industry in achieving cost reduction, efficiency improvement, and intelligent upgrading.

Selected FAQs:

Q: What are the benefits of equipment installation animations?

A: The benefits of equipment installation animations are:

1- Significantly reduces reliance on experienced installers;

2- Equipment installation is less prone to errors;

3- Beneficial for training new staff;

4- Customers perceive a higher level of professionalism.

5- Reduces installation costs and risks.

Q: Will equipment usage animations expose sensitive equipment structures?

A: No.

Equipment usage animations present the content of traditional paper operation manuals in the form of animated videos (e.g., the paper feeding unit in a printing press mainly explains how to adjust baffles, guides, and how to feed paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machinery manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always remains with the machinery manufacturer.

Q: Are equipment usage animations very expensive?

A: Let's start with the conclusion: Equipment usage animations create benefits for machinery manufacturers. The greater the investment, the greater the return.

The production cost for equipment usage animations generally ranges from tens of thousands to over a hundred thousand RMB, or even higher. While it may seem expensive on the surface, the average cost per piece of equipment is not high.

How do equipment usage animations create benefits for machinery manufacturers?

1- Low amortized cost. Machinery and equipment are generally updated slightly every 2 years and significantly every 4 years. The total cost of animation video production amortized per machine is very low;

2- Equipment premium. According to actual measurement data from machinery manufacturers, for every 1 RMB invested in producing equipment operation and maintenance animations, the resulting equipment sales premium is approximately 3-5 RMB (i.e., 3-5 times);

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively enhances customer loyalty;

5- More competitive compared to similar products.

Characteristics: Significant initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startup teams, overseas customers, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at trade shows or client visits; whether expanding overseas markets or improving after-sales service, we firmly believe that through the power of design, we can present complex products and machinery in stunning 3D animations. This not only brings a unique visual experience to clients but also quickly captivates their interest.