In manufacturing, traditional after-sales models primarily rely on passive repair, addressing equipment failures only after they occur, leading to production stagnation and increased costs. With technological advancements, 3D animation technology is revolutionizing manufacturing after-sales services, shifting them from passive repair to proactive prevention.

Technological Innovation: The After-Sales Value of 3D Animation

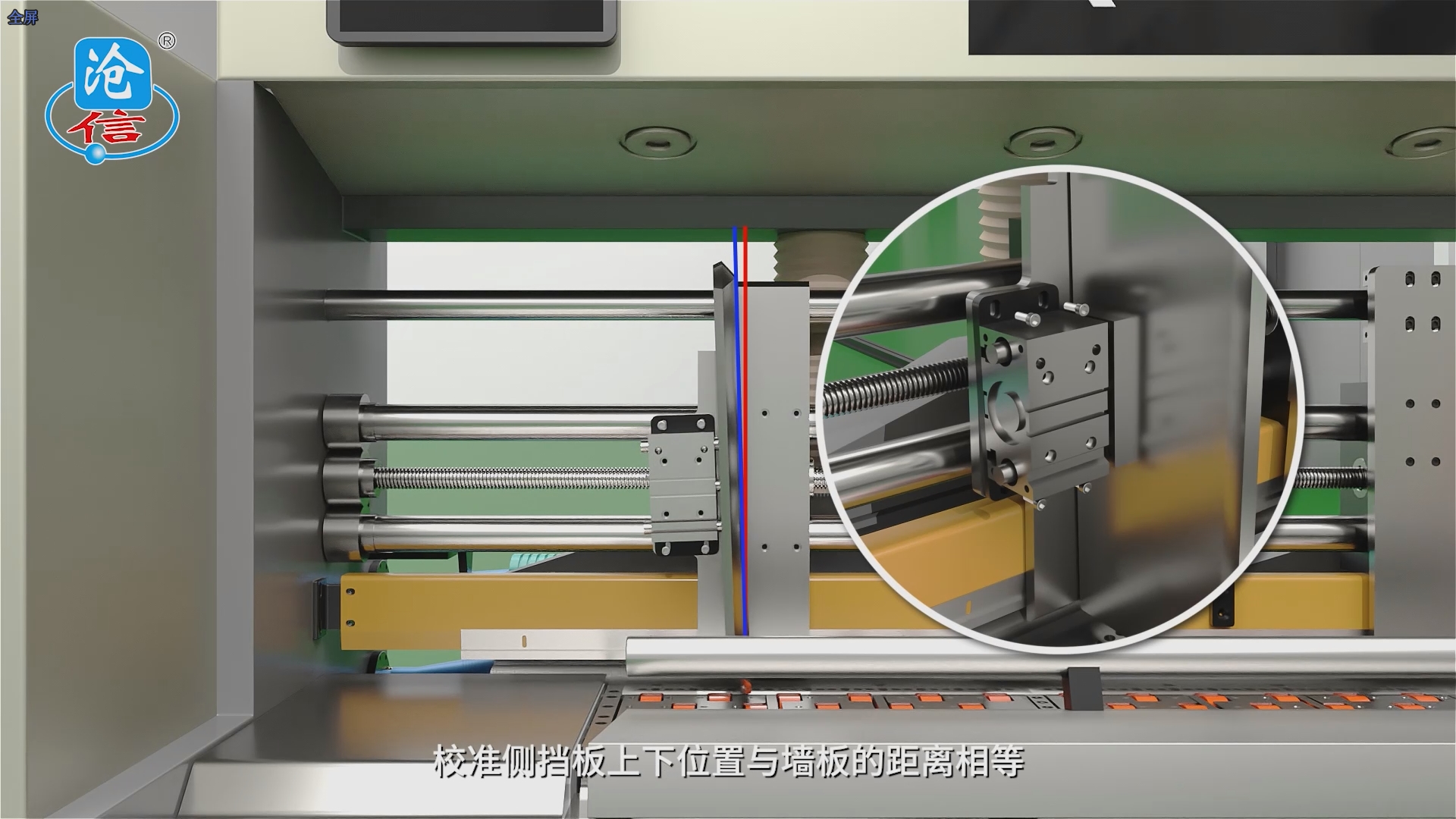

Traditional after-sales relies on manuals and 2D drawings, with information transmission being indirect and difficult for personnel to understand. 3D animation, through precise modeling, dynamic simulation, and interactive design, brings new possibilities to after-sales services. It can present the internal structure and working principles of equipment in a three-dimensional form, down to millimeter-level components, allowing maintenance personnel to intuitively understand the equipment's construction. It uses physics engines to simulate the equipment's operating processes, such as mechanical movement and fluid flow, helping maintenance personnel grasp the normal operating status of the equipment. It supports maintenance personnel interacting with the animation, such as disassembling and assembling equipment, and viewing operating conditions under different working scenarios.

Application Scenarios: Multi-dimensional Manifestations of Proactive Prevention

Fault Prediction and Diagnosis

3D animation combines with IoT sensors to collect real-time equipment operating data. Through data analysis and comparison with animated models of normal operation, potential faults can be detected in advance. A rolling mill equipment at a steel company, using 3D animation and sensor data, detected abnormal wear on the rolling bearings in advance, avoiding further equipment damage and production losses.

Remote Assistance and Training

After-sales personnel can remotely guide on-site personnel through maintenance operations using 3D animation. The animation can real-time annotate maintenance steps and key components, improving accuracy and efficiency. Simultaneously, 3D animation can be used for new employee training, allowing them to familiarize themselves with equipment maintenance procedures in a virtual environment. After-sales service personnel at Ruichang Carton Packaging Machinery Company used remote 3D animation assistance to solve equipment maintenance challenges in remote areas, saving significant time and costs.

Adaptable to Multiple Scenarios

Traditional industrial maintenance training typically relies on physical equipment and on-site guidance, which not only requires significant equipment resources but also lengthy instruction from professional trainers. Xiamen Xuncheng, through methods like rotating, perspective viewing, and zooming models, demonstrates the disassembly and assembly sequence of entire component sets and tool usage. This is complemented by voiceovers and text prompts, ensuring the standardization of the entire replacement process.

Customer Case:

Ruichang Carton Machinery Manufacturing Co., Ltd. is a specialized carton machinery manufacturer integrating R&D, production, sales, and service. After introducing 3D animation training produced by Xiamen Xuncheng, the training time for new employees was reduced from one month to two weeks, and training costs decreased by 30%. This is because 3D animation can simulate various fault scenarios, allowing trainees to practice repeatedly in a virtual environment, improving training effectiveness and reducing wear and tear on actual equipment and training time.

Concurrently, Ruichang Jinggong's after-sales service personnel provide maintenance animations to customer factories. By utilizing the 3D animation content, workers can repeatedly learn, which helps in detecting potential issues in advance, significantly reducing downtime losses, and further enhancing equipment reliability and production efficiency.

Future Outlook: Technological Integration Driving After-Sales Upgrade

In the future, 3D animation will be deeply integrated with technologies such as artificial intelligence and big data. Artificial intelligence can conduct more in-depth analysis of data within 3D animations, providing more precise fault prediction and solutions. Big data can provide more equipment operating data for 3D animations, making their simulations more realistic and accurate. It is projected that by 2026, companies adopting advanced 3D animation after-sales technology will see a 40% reduction in equipment failure rates.

Selected FAQs:

Q: How to produce 3D animations related to equipment maintenance?

A: Most machinery and production factories primarily rely on experienced, qualified electromechanical engineers for equipment maintenance. Equipment maintenance animations can effectively solve this problem.

1- It is recommended to first produce animations for common equipment fault points (including mechanical and electrical);

2- Record and document on-site repairs to accumulate material for animation production;

3- Quantity: For large equipment, it is recommended to have about 10-15 for mechanical maintenance and 5-8 for electrical maintenance initially; for medium and small equipment, about 6-8 for mechanical maintenance and 3-5 for electrical maintenance;

4- Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project personnel should be relatively stable.

Q: Will equipment usage animations expose sensitive structures of the equipment?

A: No.

Equipment usage animations are demonstrations of traditional paper operation manual content in video format (e.g., for printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to feed paper; the printing unit mainly explains how to apply ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machinery factories can also remove or deform sensitive equipment structures when providing equipment models.

The initiative is always in the hands of the machinery factory.

Q: Are equipment usage animations very expensive?

A: To conclude first: Equipment usage animations create benefits for machinery factories. The greater the investment, the greater the return.

The production cost for equipment usage animations typically ranges from tens of thousands to over a hundred thousand, or even higher. While seemingly expensive, the average cost per piece of equipment is not high.

How do equipment usage animations create benefits for machinery factories?

1- Low amortized cost. Machinery equipment undergoes minor upgrades every 2 years and major upgrades every 4 years. The total cost of animation production amortized per machine is very low;

2- Equipment premium. According to actual measurements by machinery factories, every 1 yuan invested in producing equipment operation and maintenance animations generates about 3-5 yuan in equipment sales premium (i.e., a 3-5 times return);

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively improves customer loyalty;

5- More competitive compared to similar products.

Characteristics: Significant initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startup teams, overseas clients, listed companies, to foreign-funded enterprises. Specializes in providing 3D animation creation for machinery equipment, high-tech, software development, foreign trade companies, etc. Offers one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or client visits, whether expanding overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animations. This not only brings a unique visual experience to clients but also quickly touches their hearts.