In the field of industrial production, the normal operation and maintenance of equipment are crucial. Traditional equipment maintenance training relies heavily on written manuals and on-site demonstrations, leading to difficulties in understanding and low training efficiency. The emergence of 3D animation technology has brought about new changes to industrial training, effectively addressing the pain points of traditional training.

I. 3D Animation Assists in Visualizing Complex Structures

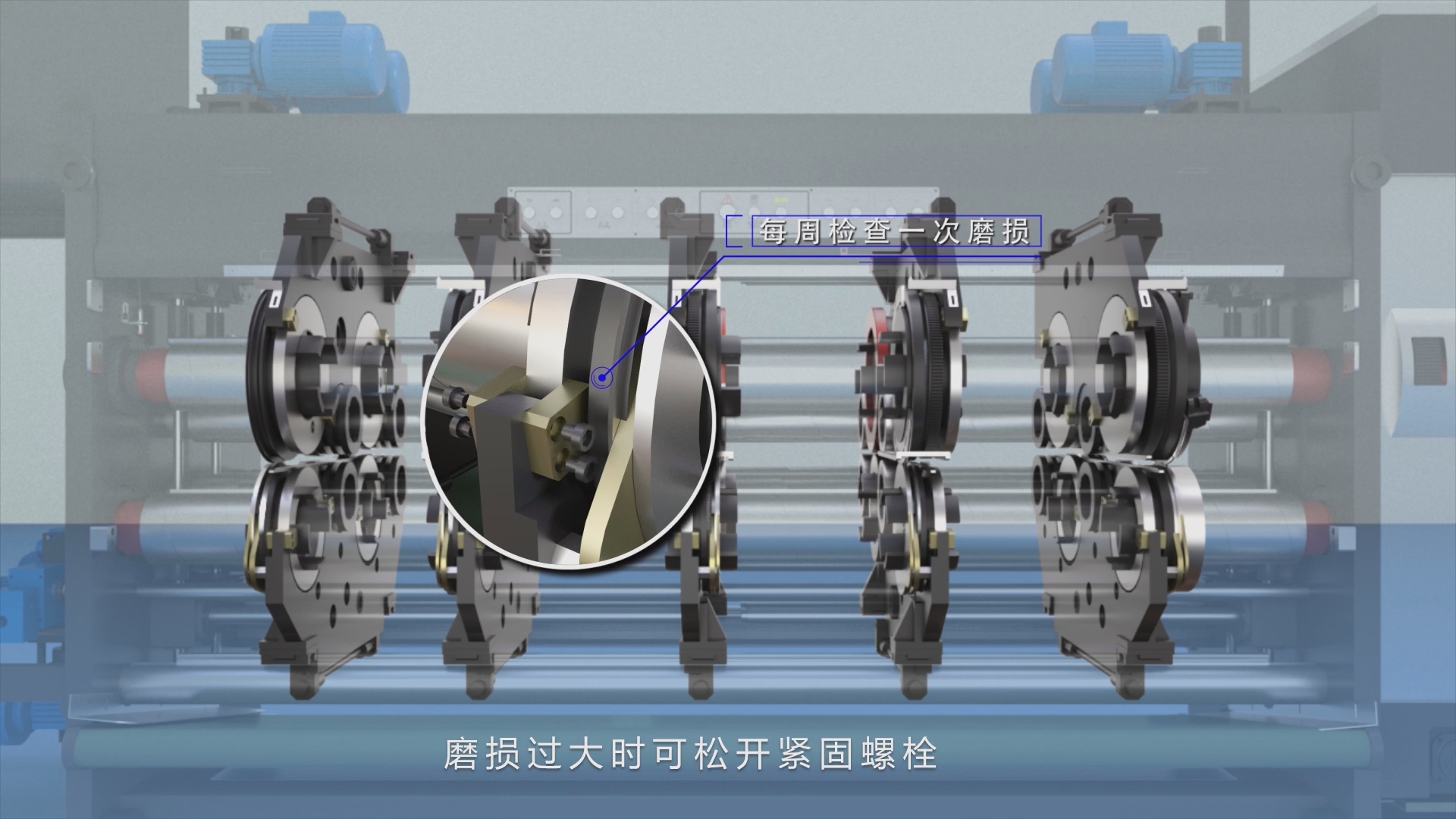

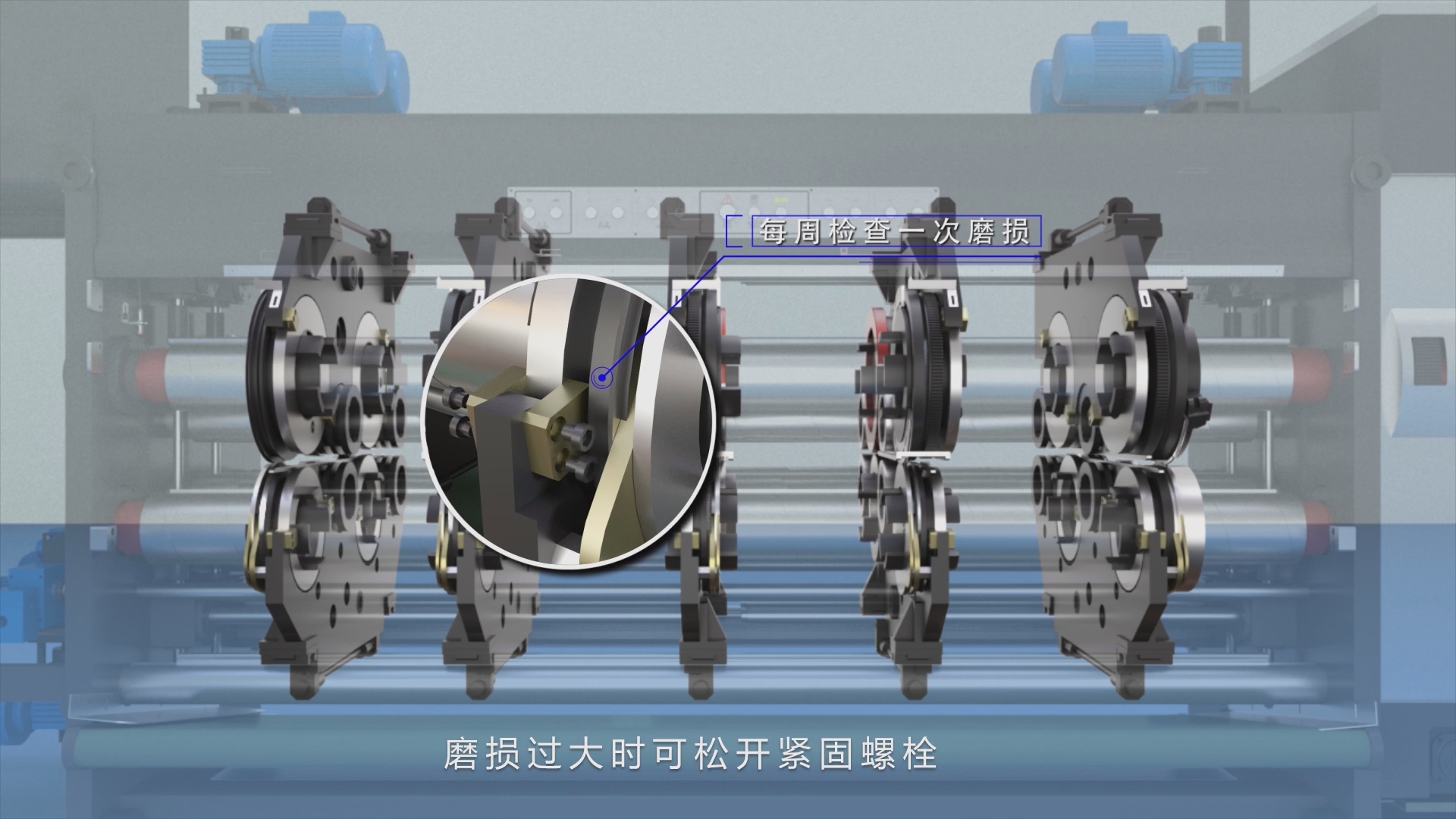

Industrial equipment usually has complex internal structures and working principles, making it difficult for trainees to understand intuitively with traditional training methods. 3D animation can create realistic equipment models, and by dynamically demonstrating the internal structure, parts movement, and workflow of the equipment, it allows trainees to easily grasp its working principles. Taking an ink printing press as an example, its internal transmission system, die-cutting tool adjustment mechanism, and other structures are complex, making it difficult to explain clearly with traditional training. With the help of 3D animation, the shape, position, and movement of each part, as well as their interactions, can be clearly displayed, greatly improving training effectiveness.

II. Simulating Maintenance Scenarios to Enhance Practical Skills

3D animation can simulate various equipment maintenance scenarios, allowing trainees to practice operations according to the animated steps. Trainees can follow the animation's guidance to perform disassembly, cleaning, lubrication, assembly, and other operations, familiarizing themselves with maintenance procedures and standards. By repeatedly practicing maintenance through animation, trainees not only improve their operational skills but also avoid potential damage and safety risks when operating on real equipment.

III. Personalized Training to Meet Diverse Needs

Trainees have different levels of knowledge and learning abilities, making it difficult for traditional training methods to cater to individual needs. 3D animation training can provide personalized training plans based on the trainee's actual situation. Trainees can choose different training modules and learning paces according to their needs. For trainees with weaker foundations, they can start by learning the basic structure and principles of the equipment; for experienced trainees, they can directly proceed to advanced maintenance skills. This personalized training approach can enhance trainees' motivation and learning outcomes.

IV. Reducing Training Costs and Improving Efficiency

Traditional equipment maintenance training requires the use of real equipment and extensive training materials, resulting in higher costs. Furthermore, costs may increase during training due to equipment damage or material waste. 3D animation training does not require real equipment; it only involves simulated operations on a computer, significantly reducing training costs. Moreover, 3D animation training can be conducted anytime, anywhere, without time or space constraints, allowing trainees to learn according to their own schedules, thus improving training efficiency.

V. Case Study

Guangdong Toprint Intelligent Machinery Technology Co., Ltd. is a company specializing in the production of high-end ink printing presses, with products sold to many countries and regions domestically and internationally. The company integrates equipment operation and maintenance animations into tablet iPads embedded in the control console, facilitating training for employees and customer factories. This visual design transforms abstract maintenance standards into executable steps, reducing the risk of human error. It enables customers and employees to master operational skills faster, quickly understand product usage, and reduce training and after-sales service costs.

In actual customer production sites, Guangdong Toprint's after-sales service engineers can also guide production operators in equipment maintenance and upkeep through animations. Many customers have stated that by watching the animations combined with the engineers' guidance, they have gained a clearer understanding of equipment maintenance, achieving trouble-free operation of the equipment.

In summary, 3D animation has irreplaceable advantages in industrial equipment maintenance training. It can improve training effectiveness, enhance trainees' practical skills, meet personalized needs, and reduce training costs, providing strong support for industrial enterprises in cultivating high-quality equipment maintenance talent. Xiamen Xuncheng specializes in industrial 3D animation design and production, boasting a professional technical team and rich experience in the manufacturing industry, enabling them to tailor high-quality 3D animation training solutions for enterprises, helping them enhance training levels and competitiveness.

Featured FAQs:

Q: Which equipment is suitable for creating operation and maintenance animations?

A: Almost all equipment is suitable for creating operation and maintenance animations, from large single units costing millions to small ones costing tens of thousands or even thousands of yuan. Creating equipment operation and maintenance animations helps solve after-sales service issues, enhances brand and product value, promotes sales, and increases customer loyalty.

Q: Are operation and maintenance animations very expensive?

A: To conclude upfront: Equipment operation and maintenance animations create value for machinery factories. The greater the investment, the greater the return. The production cost for equipment operation and maintenance animations generally ranges from tens of thousands to over a hundred thousand yuan, or even higher. While seemingly expensive on the surface, the average cost per unit is not high. How do equipment operation and maintenance animations create value for machinery factories? 1. Low amortized cost. Machinery equipment typically undergoes minor modifications every 2 years and major ones every 4 years; the total cost of animation production is very low when amortized per unit. 2. Equipment premium. Based on actual data from machinery factories, every yuan invested in creating equipment operation and maintenance animations generates approximately 3-5 yuan in sales premium (i.e., 3-5 times return). 3. Significantly reduces after-sales service costs, especially during the warranty period. 4. Effectively increases customer loyalty. 5. Enhances competitiveness compared to similar products. Characteristic: High initial investment, very low subsequent investment.

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No. Operation and maintenance animations present the content of traditional paper operation manuals in the form of animated videos (e.g., in a printing press, the paper feeding unit primarily explains how to adjust baffles and guides, and how to load paper; the printing unit primarily explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machinery factories can also delete or modify sensitive equipment structures when providing equipment models. The control always remains with the machinery factory.

About Xuncheng Technology

Founded in 2016, with 9 years of professional experience in industrial 3D animation creation, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech, software development, foreign trade companies, and more. We offer one-stop industrial 3D animation creative services, from product sales to after-sales maintenance. We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises. Whether at trade shows or client visits, whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with astonishing 3D animations. This not only brings a unique visual experience to clients but also swiftly moves them.

About Xuncheng Technology

Founded in 2016, with 9 years of professional experience in industrial 3D animation creation, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech, software development, foreign trade companies, and more. We offer one-stop industrial 3D animation creative services, from product sales to after-sales maintenance. We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises. Whether at trade shows or client visits, whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with astonishing 3D animations. This not only brings a unique visual experience to clients but also swiftly moves them.