In industrial production, stable equipment operation is crucial, and the timely and correct replacement of wearable parts (such as bearings, seals, filter elements, etc.) is the core link to ensuring stable equipment operation. However, traditional parts replacement manuals rely on textual descriptions, simple diagrams, or on-site training, which suffer from ambiguous operating steps and missed technical points, leading to low replacement efficiency, high error rates, and even malfunctions that affect production. Wearable parts replacement animation, as an innovative visualization tool, can effectively solve these problems and provide strong support for enhancing equipment reliability.

I. Technical Implementation of Wearable Parts Replacement Animation

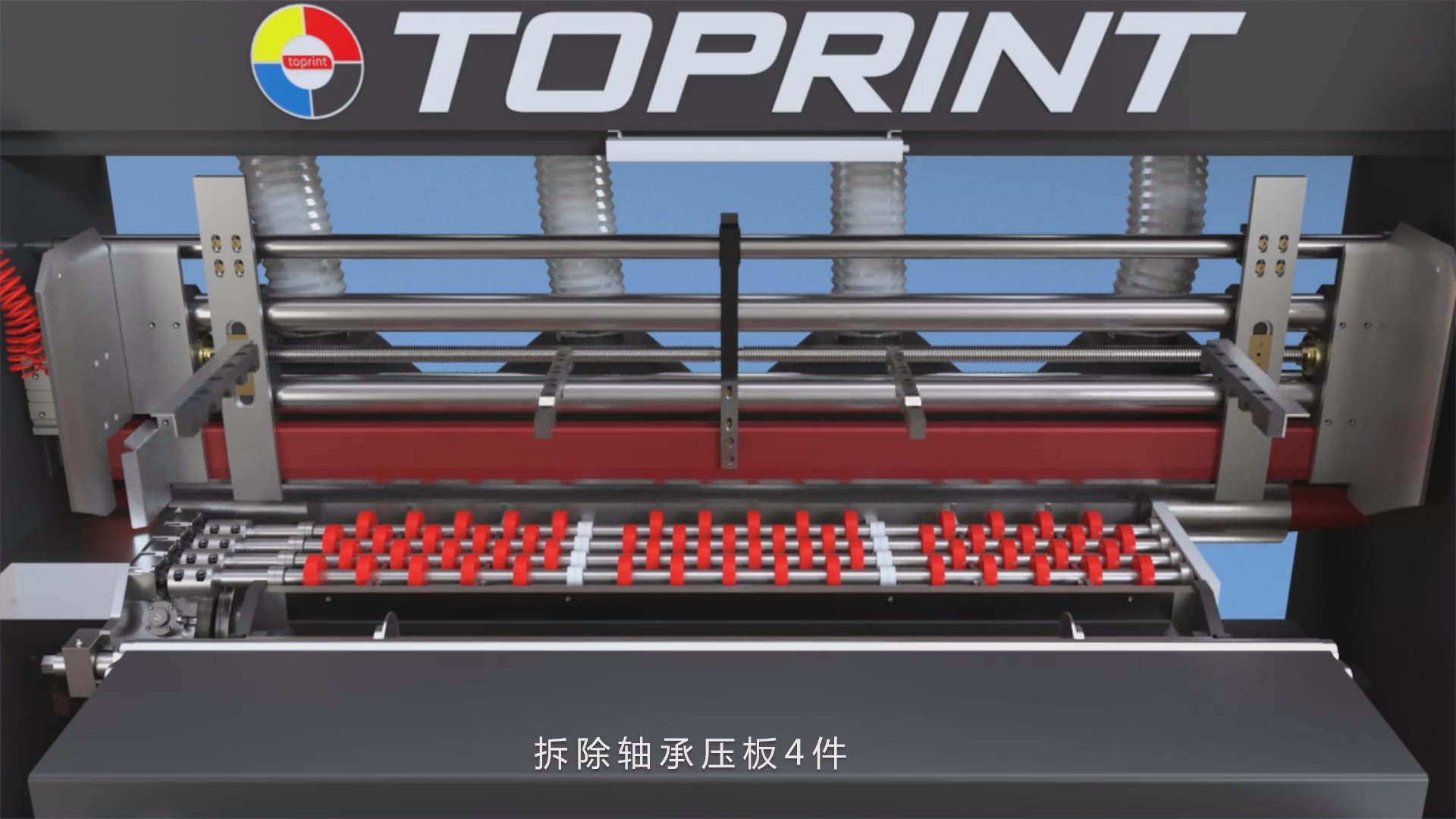

Wearable parts replacement animation utilizes 3D modeling technology to accurately restore the equipment's appearance, internal structure, and the position and form of wearable parts. Through dynamic demonstrations, it clearly shows the steps for disassembling and installing equipment wearable parts, including details such as tool usage, operating force, and sequence. Using 3D animation technology to display close-ups and extreme close-ups, it simulates real replacement scenarios, allowing operators to familiarize themselves with potential problems and solutions in advance.

II. Application Scenarios and Advantages

Guangdong Tuopin Intelligent Machinery Technology Co., Ltd. is a company specializing in the production of high-end water-based ink printing machines, with products exported to many countries and regions domestically and internationally. Customers in different regions have varying levels of understanding regarding the operation, maintenance, and repair of water-based ink printing machines. To meet customer needs, the manufacturer commissioned Xiamen Xuncheng to produce animation videos demonstrating the operation process of the entire machine.

(I) Operator Training

Upon new employee onboarding, Tuopin Intelligent uses wearable parts replacement animation as standardized training material, replacing the limitations of traditional 'learn-by-doing' on-site training by a master. The company uses animation to train new employees, enabling them to master the skills for replacing most wearable parts of the machinery and equipment in a short period, significantly shortening the training cycle.

(II) On-site Operation Guidance

During actual parts replacement on customer sites, Tuopin Intelligent's after-sales service engineers can also guide operators to work alongside the animation. Many customers have stated that by watching the animation in conjunction with the engineer's guidance, they gained a clearer understanding of equipment operation, and customer satisfaction with after-sales service has significantly improved.

(III) Remote Technical Support

When on-site operators encounter difficulties and seek remote assistance, Tuopin Intelligent's technicians can provide remote guidance through the animation. This not only avoids the frequent on-site visits of after-sales service engineers but also saves time and costs for the manufacturing enterprise.

III. Role in After-Sales Service

According to recent exchanges with Tuopin's after-sales service team, the entire staff has given very high praise for the enhancement of after-sales service facilitated by 3D animation.

Reduced operational errors: The intuitive display of the animation allows operators to accurately grasp the replacement steps, reducing equipment damage caused by improper operations. Improved replacement efficiency: Clear animated demonstrations enable operators to quickly complete wearable parts replacement, shortening equipment downtime. Ensured equipment performance: Timely and correct replacement of wearable parts allows equipment to maintain good operating condition at all times, extending its service life.

It can be affirmed that wearable parts replacement animation, through visualization, has solved the challenges of traditional manual guidance and played a crucial role in operator training, on-site operation, and remote support. It effectively reduces operational errors, improves replacement efficiency, ensures equipment performance, and is a visual key to enhancing equipment reliability. With continuous technological development, wearable parts replacement animation will be more widely applied in the industrial field.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients across various types of enterprises including startups, overseas customers, listed companies, and foreign-funded enterprises. Specializing in providing 3D animation creation for machinery and equipment, high-tech industries, software development, and foreign trade companies. Offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibitions or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animation. This not only brings a unique visual experience to clients but also profoundly impresses them.