Driven by the waves of Industry 4.0 and intelligent manufacturing, packaging and printing equipment are undergoing a profound transformation from automation to intelligence. 3D animation technology, as an important digital tool, is playing a key role in this transition, propelling the industry towards more intelligent and efficient development.

Intelligent Evolution in Equipment R&D and Design Phase

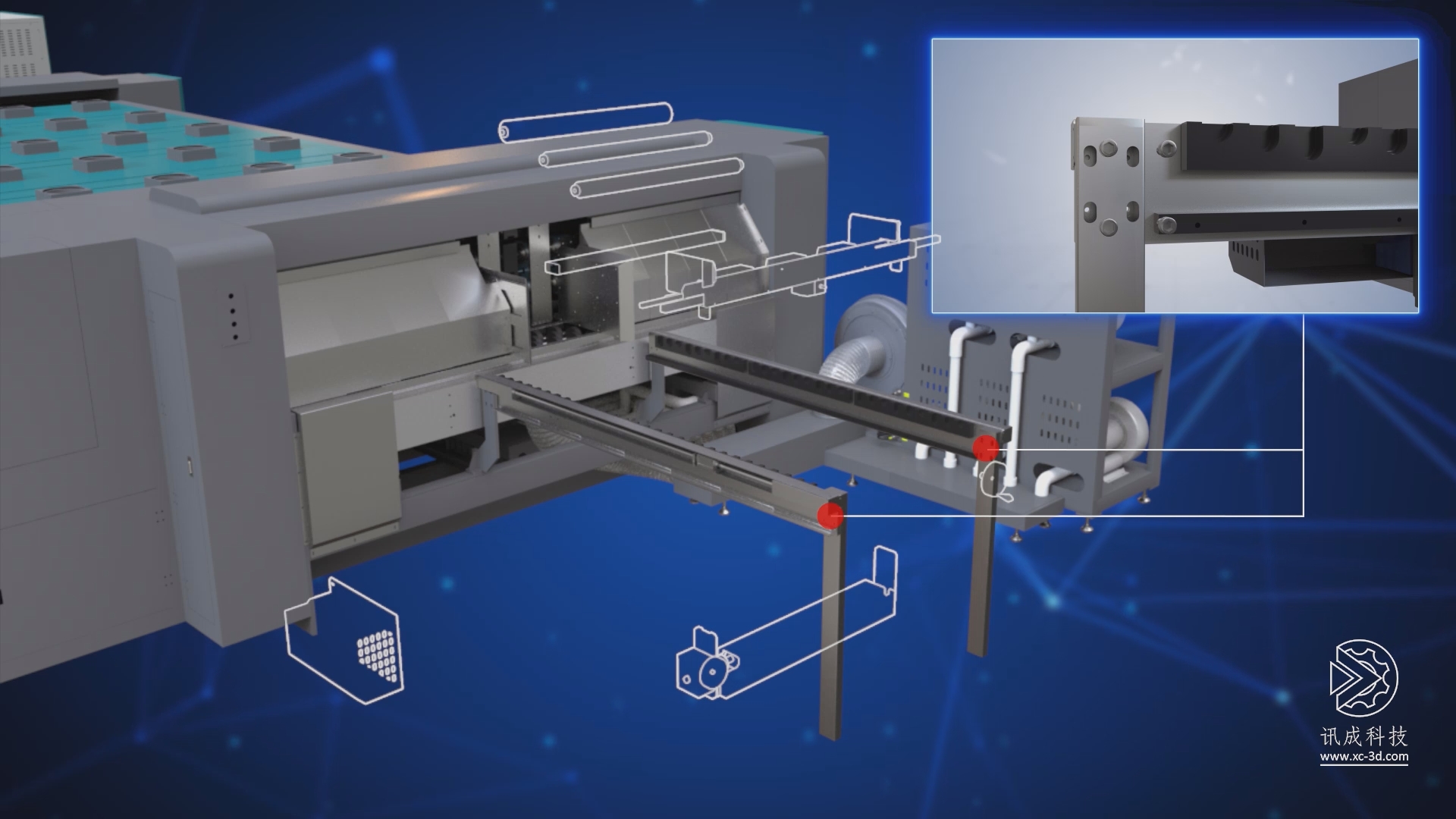

In the R&D and design phase of packaging and printing equipment, 3D animation technology is changing traditional design models. By building precise digital prototypes, designers can simulate equipment operating status in a virtual environment and optimize design solutions. Guangdong Topin Intelligent Machinery's R&D team used 3D animation technology to discover multiple potential issues during the design phase of a new ink printing machine, shortening the product R&D cycle by 40% through real-time adjustment of design solutions.

More importantly, 3D animation makes the simulation analysis of complex mechanical systems more intuitive. Designers can observe the dynamic characteristics of equipment during high-speed operation through animation demonstrations, predicting potential issues such as vibration and wear. This advanced simulation analysis not only improves equipment reliability but also lays a solid foundation for the implementation of intelligent functions.

Digital Upgrade of Production and Manufacturing Processes

3D animation technology also plays an important role in the production and manufacturing stages of packaging and printing equipment. By building digital twin models, enterprises can achieve deep integration of virtual manufacturing and real production. Xiamen Huist Intelligent Technology Co., Ltd. has established a complete digital factory model using 3D animation technology, enabling real-time monitoring and optimization of the production process.

In practical applications, 3D animation systems can simulate the operating status of the entire production line, identify production bottlenecks in advance, and optimize equipment configuration. Huist Enterprise's practical data shows that after adopting a digital manufacturing system based on 3D animation, production line efficiency increased by 25%, and equipment debugging time was reduced by 50%. This digital upgrade lays a solid foundation for intelligent production.

Intelligent Innovation of Operating Interfaces

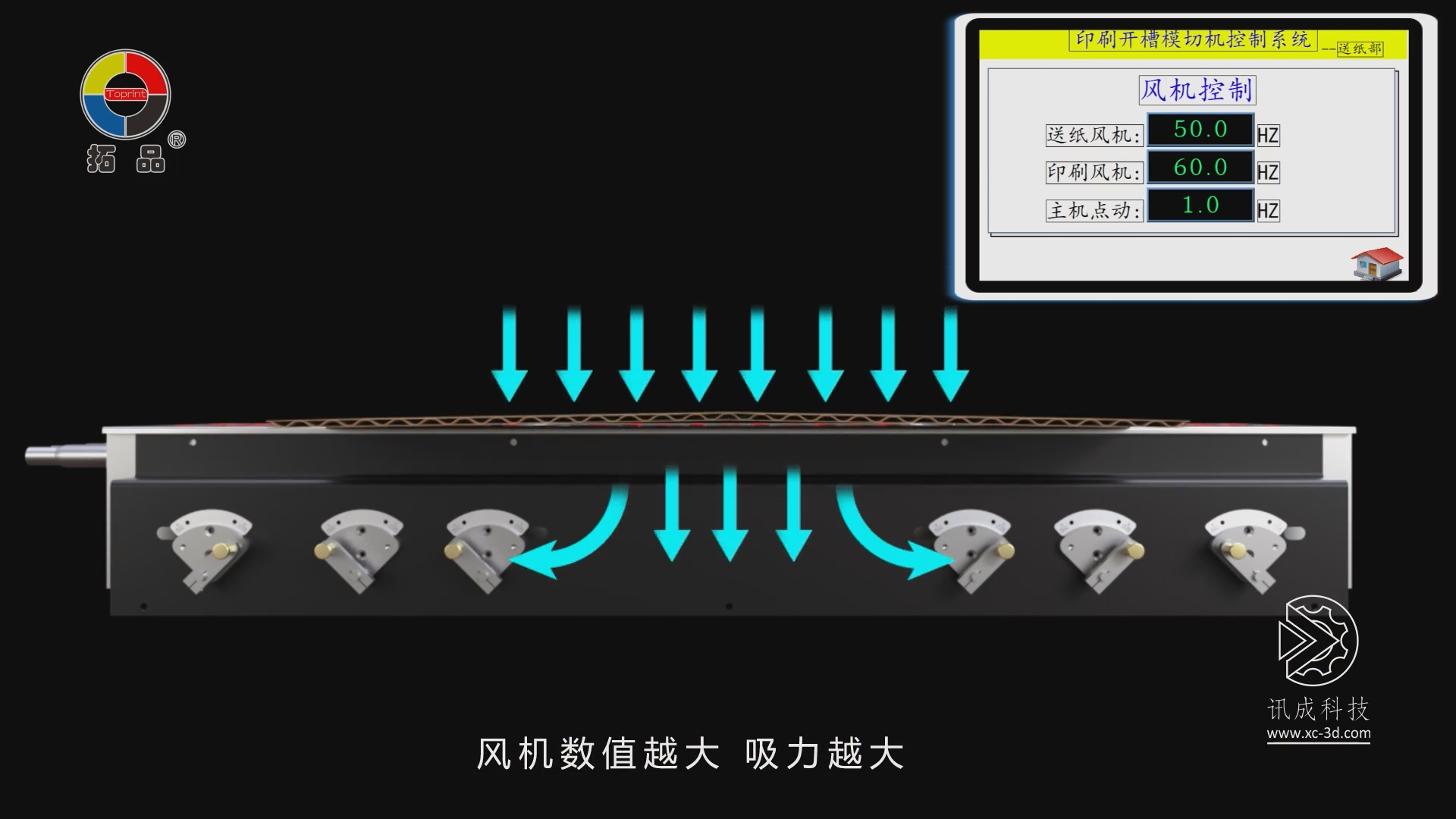

3D animation technology is also driving intelligent innovation in the operating interfaces of packaging and printing equipment. Traditional equipment operating interfaces are often complex and difficult to understand, while intelligent operating interfaces based on 3D animation significantly reduce operational difficulty through visual guidance.

Topin Intelligent has adopted an intelligent operating interface based on 3D animation in its new generation of printing equipment. Operators can interact directly with the 3D model via a touchscreen, intuitively understanding equipment status and operating procedures. This innovative operating method has shortened new employee training time by 60% and reduced the error rate by 45%. More importantly, the system can automatically adjust the level of detail in prompts based on the operator's skill level, achieving true intelligent interaction.

Intelligent Enhancement of Remote Services

The integration of 3D animation with IoT and big data technology is driving the intelligent upgrade of remote services for packaging and printing equipment. Based on the establishment of an intelligent service system, remote services can be made intelligent through real-time data collection and 3D animation guidance. When equipment anomalies occur, the system can automatically analyze fault data and provide precise maintenance guidance to on-site technicians through 3D animation.

Concurrently, remote experts can use augmented reality technology to overlay guidance information directly onto the actual equipment, achieving intelligent guidance of 'what you see is what you get.' This intelligent remote service model has improved problem-solving efficiency by 70% and reduced service costs by 40%.

Data Visualization Support for Intelligent Decision-Making

Under the trend of intelligent development, 3D animation technology also provides important support for intelligent decision-making in packaging and printing equipment. By presenting equipment operating data in a visual format, managers can more intuitively understand equipment status and make more accurate decisions.

Shenzhen Wande Shuke Enterprise uses a 3D animation data visualization system to display equipment operating efficiency, energy consumption status, and quality indicators in real-time. The system analyzes historical data using intelligent algorithms to predict equipment performance trend changes, providing support for production planning and maintenance decisions. This data-driven intelligent decision-making model has increased equipment utilization by 35% and reduced energy consumption by 20%.

Intelligent Outlook for Future Development

With continuous technological advancements, the application of 3D animation in the intelligent development of packaging and printing equipment will become more profound. The integration of artificial intelligence technology will enhance equipment self-learning and adaptive capabilities; the application of 5G technology will support higher-quality real-time data interaction; the development of digital twin technology will promote deeper integration of virtual and real worlds.

In the future, packaging and printing equipment will achieve a higher degree of intelligence. Equipment will be able to autonomously diagnose problems, predict maintenance needs, and even automatically optimize operating parameters through 3D animation systems. These innovations will drive the packaging and printing industry towards a more intelligent and efficient direction, creating greater value for enterprises.

In summary, 3D animation technology is profoundly changing the development trajectory of packaging and printing equipment, driving the industry's rapid evolution towards intelligence. From R&D and design to production and manufacturing, from operation and maintenance services to decision support, its application value has been fully demonstrated in every link. With continuous technological innovation and deepening applications, 3D animation will undoubtedly play an even more important role in the intelligent process of packaging and printing equipment, injecting sustained momentum into industry innovation and development.

Featured FAQs:

Q: What categories does Xuncheng Animation video production include?

A: Animation video production includes the following three categories: Promotional: including product promotion, corporate promotion, etc. Technical: including equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, equipment safety, etc. Customized: including videos for exhibitions, investment promotion, event warm-ups, etc.

Q: How to produce 3D animations related to equipment maintenance?

A: Most machinery and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment repair animations can effectively address this issue. 1. It is recommended to first produce animations for common equipment fault points (including mechanical and electrical); 2. Record and document on-site maintenance to gather material for animation production; 3. Quantity: It is recommended to produce about 10-15 mechanical repair animations and 5-8 electrical repair animations for large equipment initially; for medium and small equipment, about 6-8 mechanical repair animations and 3-5 electrical repair animations; 4. Equipment repair animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project liaison personnel should be relatively stable.

Q: Which equipment is suitable for producing operation and maintenance animations?

A: Almost all equipment is suitable for producing operation and maintenance animations, from single machines worth millions to those costing tens of thousands or even thousands of yuan. Producing operation and maintenance animations for equipment helps solve after-sales service issues, enhances brand and product premium, promotes sales, and increases customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech, software development, foreign trade companies, etc., offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance. We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises. Whether at exhibition sites or during client visits, whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animation. This not only brings a unique visual experience to clients but also quickly resonates with them.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animation. This not only brings a unique visual experience to clients but also quickly resonates with them.