In today's increasingly competitive manufacturing landscape, the quality of after-sales service has become a critical factor determining a company's success. Traditional after-sales service models are predominantly characterized by "passive response," meaning customers report issues after equipment failure, and engineers are dispatched to the site for diagnosis and repair. When equipment malfunctions, it is difficult to accurately describe complex phenomena through phone calls or text. Even experienced engineers require considerable time and effort to troubleshoot problems on-site, especially for large, complex internal structures of equipment. This approach not only results in slow response times and high costs but also leads to extended downtime, causing significant production losses for customers. However, with the maturity and application of 3D industrial animation technology, manufacturing after-sales service is undergoing a profound transformation.

Visual Tools Reshape After-sales Service System

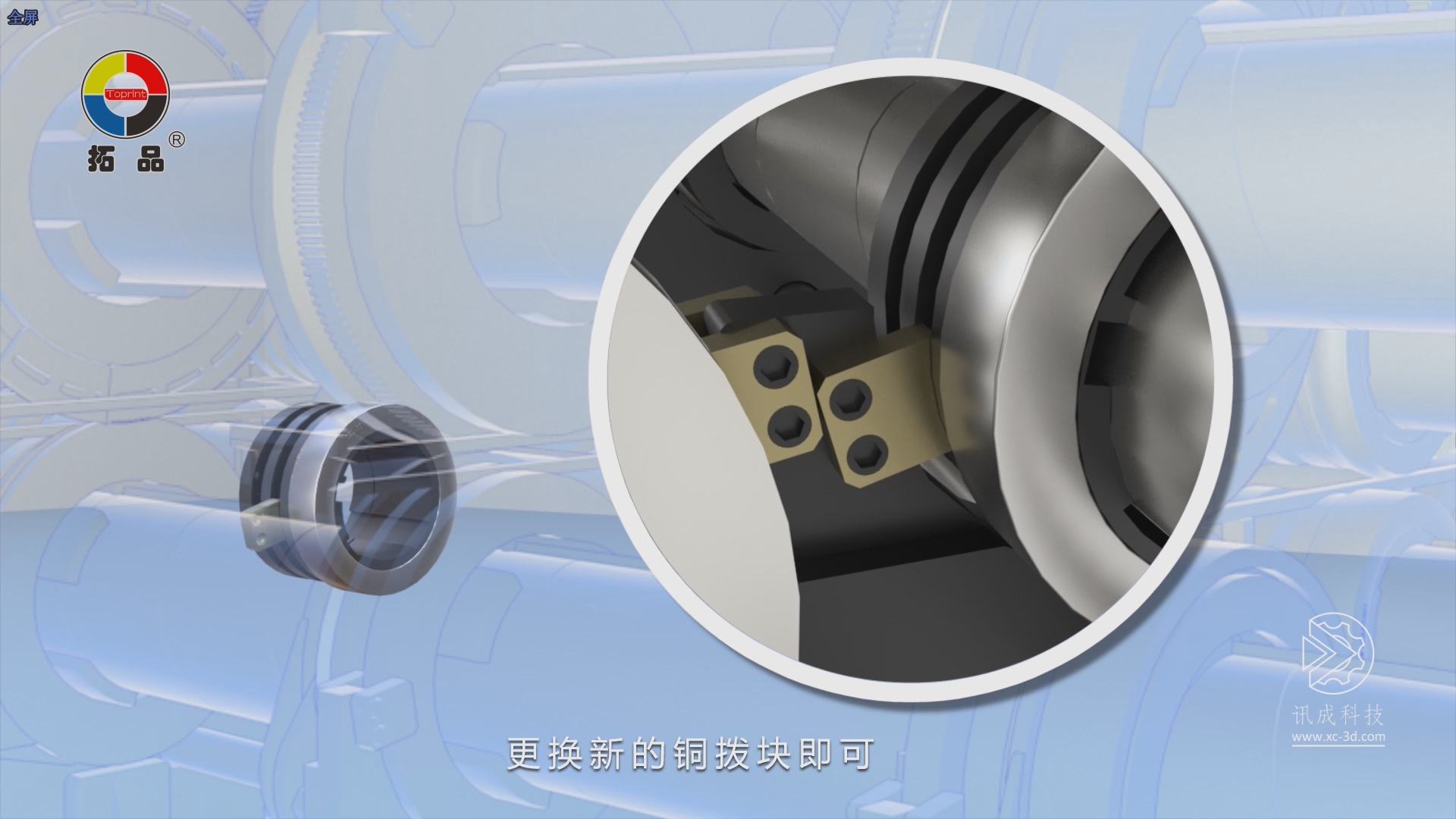

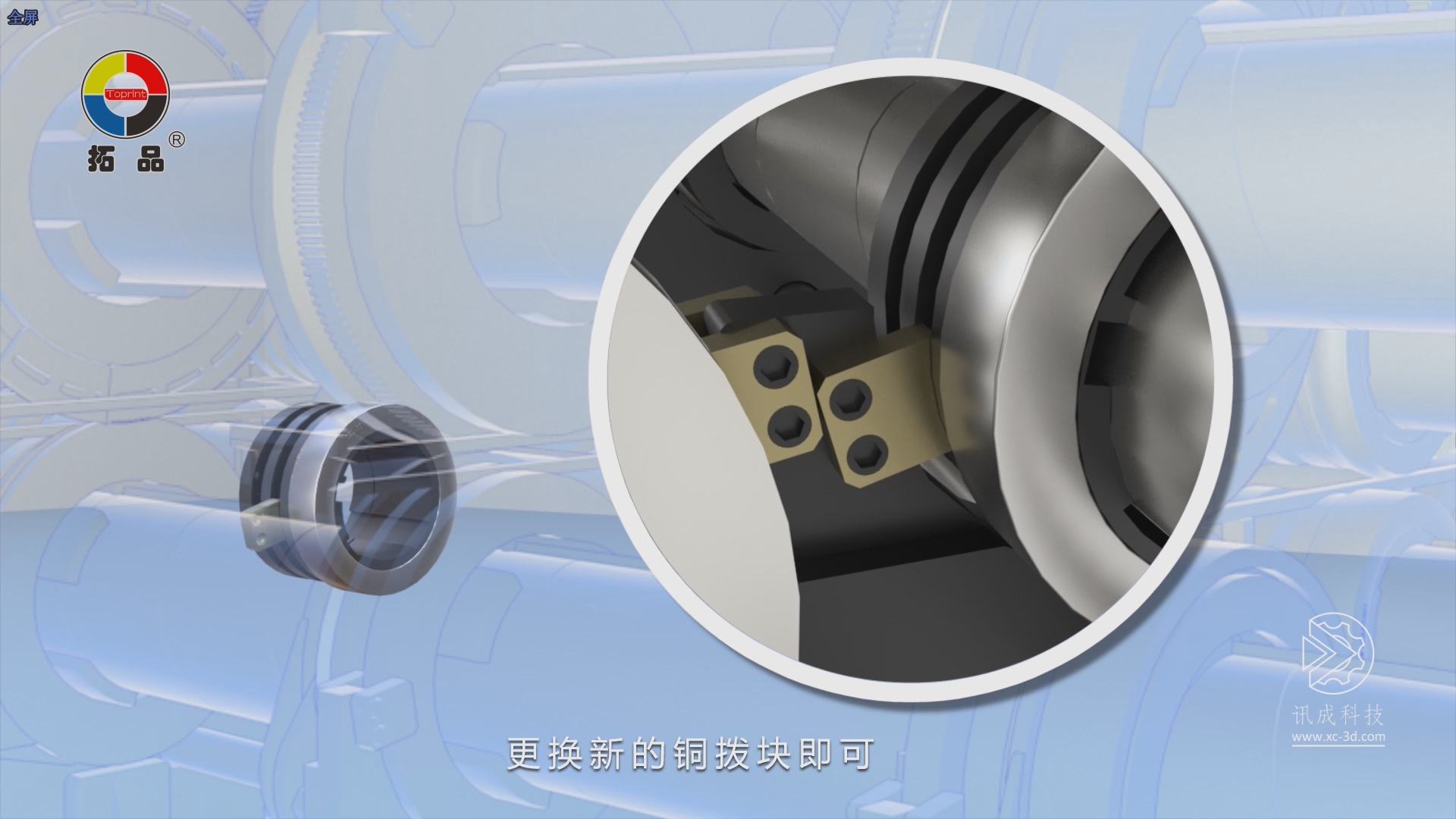

3D industrial animation, with its intuitive, precise, and interactive characteristics, provides a brand new solution for manufacturing after-sales service. Taking Guangdong Tuopin Intelligent Machinery Technology Co., Ltd.'s high-speed inkjet printing machine as an example, the maintenance animations produced by Xiamen Xuncheng can accurately demonstrate the correct sequence for disassembling various components and important precautions. Maintenance personnel can familiarize themselves with the entire process through the animation in advance, greatly shortening on-site diagnosis and operation time, avoiding secondary damage caused by improper operation, and significantly improving the first-time success rate of repairs.

The value of this visualization tool is particularly prominent in new employee training. The digital printing machine series animations by Shenzhen Wander Digital Technology Co., Ltd. cover the entire process of operation, maintenance, replacement, and fault diagnosis, and support multilingual and tablet learning. This enables their customers to perform self-maintenance, reduces employee training time by 40%, and significantly decreases the rate of operational errors. Animation training not only accelerates the growth of new employees but also solidifies the experience of veteran technicians, achieving efficient knowledge transfer and reuse.

Strategic Shift from Passive Response to Proactive Prevention

The application of 3D animation is driving the transformation of after-sales service from "firefighting" to "fire prevention". By visually marking maintenance points, locations of wear parts, and replacement cycles of equipment through animation, customers can be proactively reminded to perform regular maintenance, eliminating potential faults in their nascent stage. The multilingual 3D animations produced by Foshan Jinbing Machinery Co., Ltd. for their packaging equipment clearly display the maintenance procedures and locations of wear parts. This not only solves the language barrier issue for overseas customers but also guides customers to form regular maintenance habits, effectively preventing sudden failures and reducing unplanned downtime.

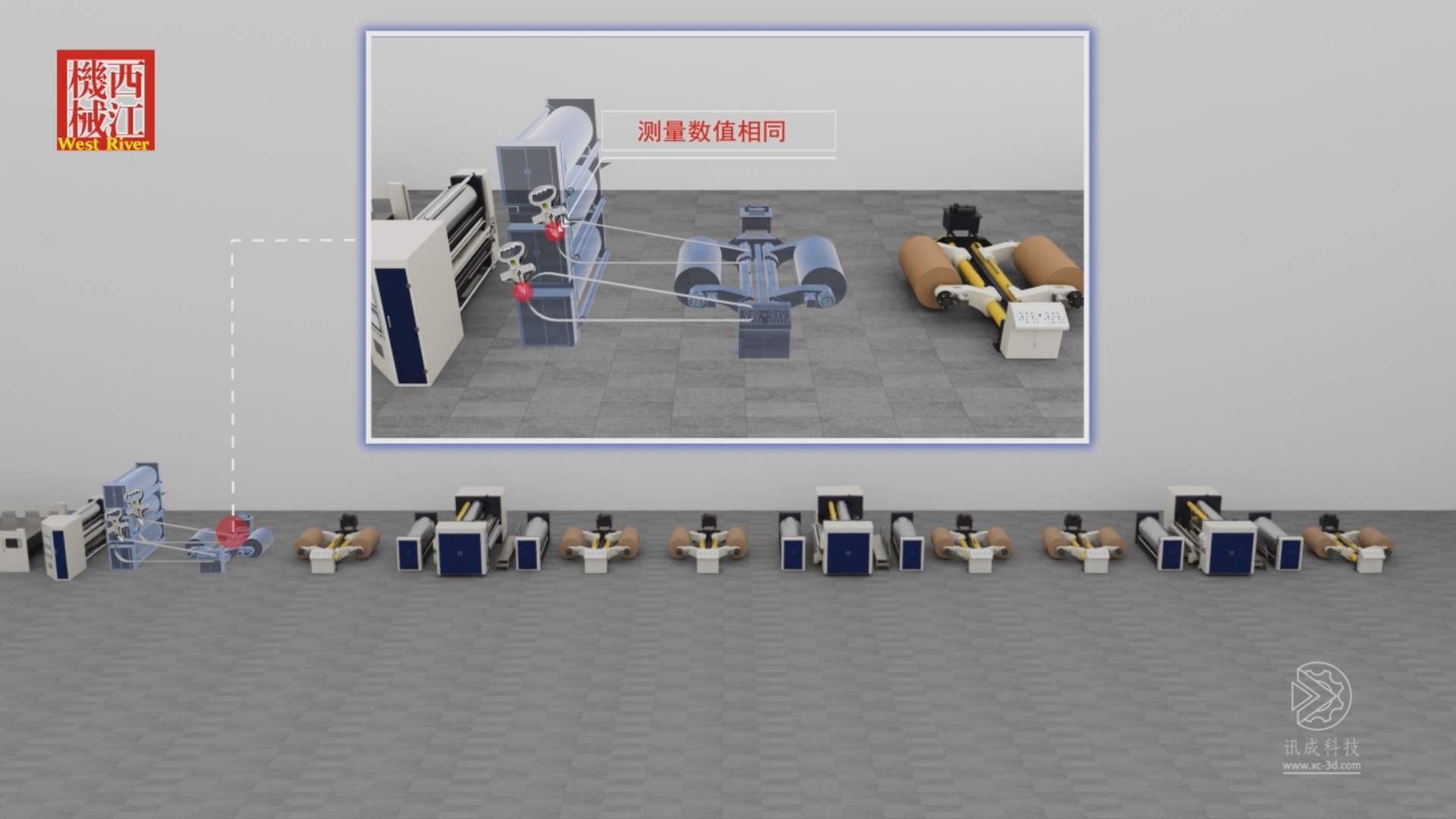

In special circumstances, when engineers cannot immediately reach the site, 3D installation or maintenance animations become the perfect tool for remote guidance. Guangdong Zhaoqing Xijiang Machinery Manufacturing Co., Ltd. once used equipment installation animations for remote guidance, clearly demonstrating components, installation sequences, and debugging parameters. This effectively solved the problem of engineers being unable to install on-site due to epidemic or geographical restrictions, ensuring the timely progress of projects.

Building an Intelligent After-sales New Ecosystem

With the integration of technologies like Augmented Reality (AR), 3D animation is becoming an indispensable part of the digital transformation in manufacturing. In the future, maintenance personnel can directly overlay animation instructions onto real equipment via AR glasses, achieving "what you see is what you repair", further lowering the operational threshold, and enhancing safety and accuracy. This integration of technology not only changes traditional maintenance methods but also redefines the service relationship between manufacturing enterprises and their customers.

3D animation solutions provided by service providers like Xiamen Xuncheng are helping numerous manufacturing enterprises build a more efficient, accurate, proactive, and low-cost modern after-sales service system. This transformation not only enhances service quality but also fundamentally strengthens the market competitiveness of enterprises. While creating greater value for customers, it also opens up new service value-added space for manufacturing enterprises.

Selected FAQs:

Q: How to produce 3D animations related to equipment maintenance?

A: Most mechanical and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animations can solve this problem effectively.

1- It is recommended to first produce animations for common equipment failure points (including mechanical and electrical);

2- Record and document on-site maintenance to accumulate material for animation production;

3- Quantity: It is recommended to produce about 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment initially; for medium and small equipment, about 6-8 mechanical maintenance animations and 3-5 electrical maintenance animations;

4- Equipment maintenance animation is a process of continuous accumulation and optimization with a relatively long production cycle. Project contact personnel should be relatively stable.

Q: How can a small company without an "Equipment Operation Manual" produce operation and maintenance animations?

A: Xuncheng can provide a full-chain service for the production of equipment operation and maintenance animations. Specific steps are as follows:

1- After the equipment is installed and debugged, mechanical plants can record on-site training sessions using multiple fixed cameras and convert them into documents (Xuncheng can also provide this service);

2- Xuncheng will categorize and optimize the relevant content;

3- The documents will be sent to the mechanical plant for confirmation;

4- Animation will be produced.

Q: Are equipment usage animations very expensive?

A: Conclusion first: Equipment usage animations create benefits for mechanical plants. The greater the investment, the greater the return.

The production cost of equipment usage animations generally ranges from tens of thousands to over a hundred thousand, or even higher. While it may seem expensive on the surface, the average cost per piece of equipment is not high.

How do equipment usage animations create benefits for mechanical plants?

1- Low amortized cost. Machinery and equipment are generally updated slightly every 2 years and significantly every 4 years. The total cost of animation video production is very low when amortized per unit;

2- Equipment premium. According to actual measurement data from mechanical plants, for every yuan invested in producing equipment operation and maintenance animations, the resulting equipment sales premium is about 3-5 yuan, i.e., 3-5 times;

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively increases customer stickiness;

5- More competitive compared to similar products.

Features: Large initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises.

We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc.

We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animations.

This not only brings a unique visual experience to clients but also quickly impresses them.