After-sales services in manufacturing are facing triple challenges of response speed, cost control, and technology inheritance. The traditional after-sales model relies on on-site engineer services, which are not only costly but also limited in efficiency. The introduction of 3D industrial animation technology is fundamentally changing this situation, bringing significant cost reduction and efficiency improvement results to manufacturing after-sales services through visualization, standardization, and intelligent methods.

Visual Guidance: Reducing Reliance on On-site Services

Remote fault diagnosis and repair have become a primary application scenario for 3D animation. Xiamen Xuncheng created a repair animation for ink printing machines for Guangdong Tuopin Intelligent Machinery, turning common troubleshooting processes into interactive 3D guides. When a customer's equipment malfunctions, technical service personnel can remotely access relevant animation clips to guide on-site operators through basic troubleshooting. This model allows approximately 40% of routine issues to be resolved remotely, reducing the cost per service by over 60%.

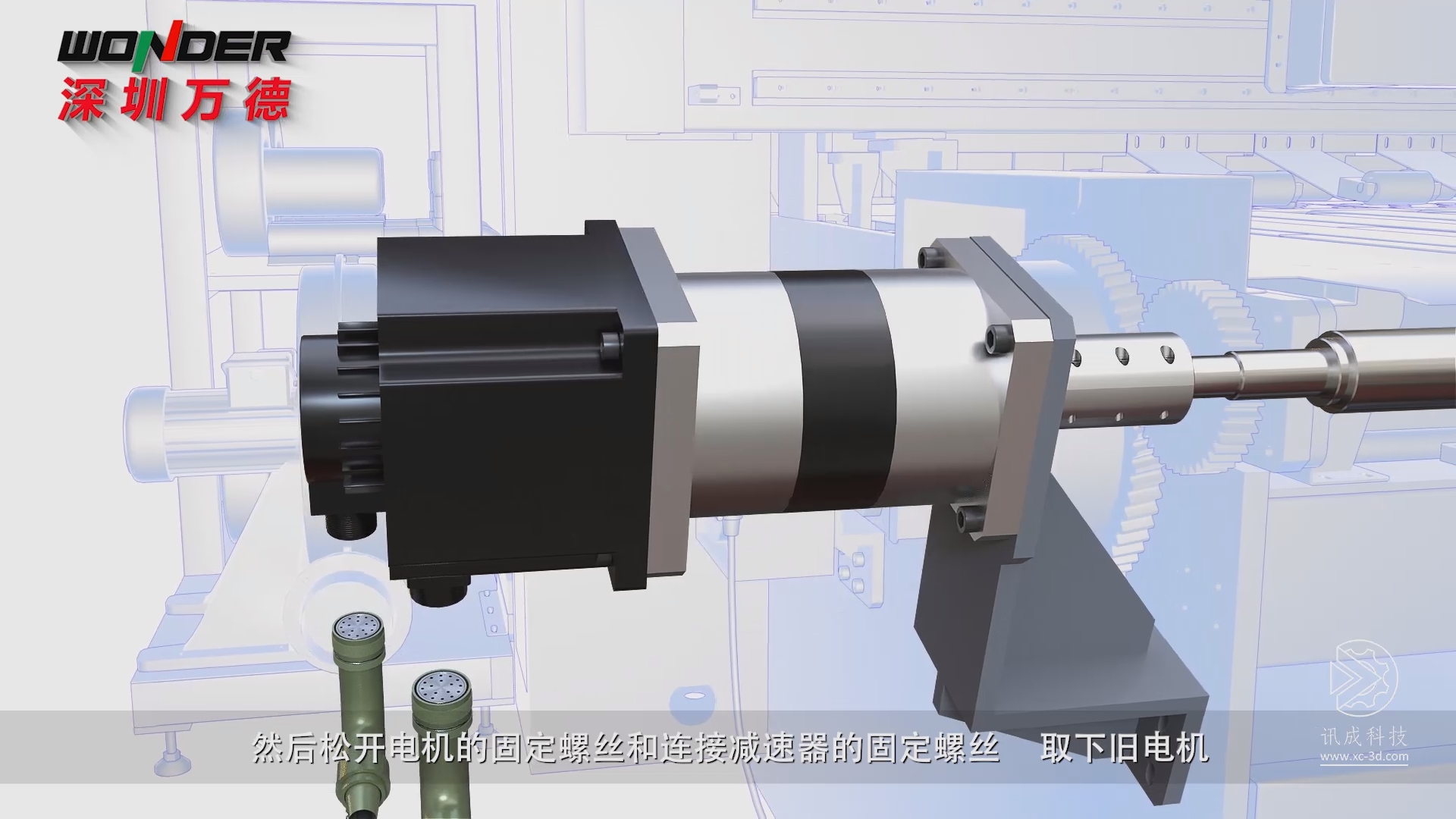

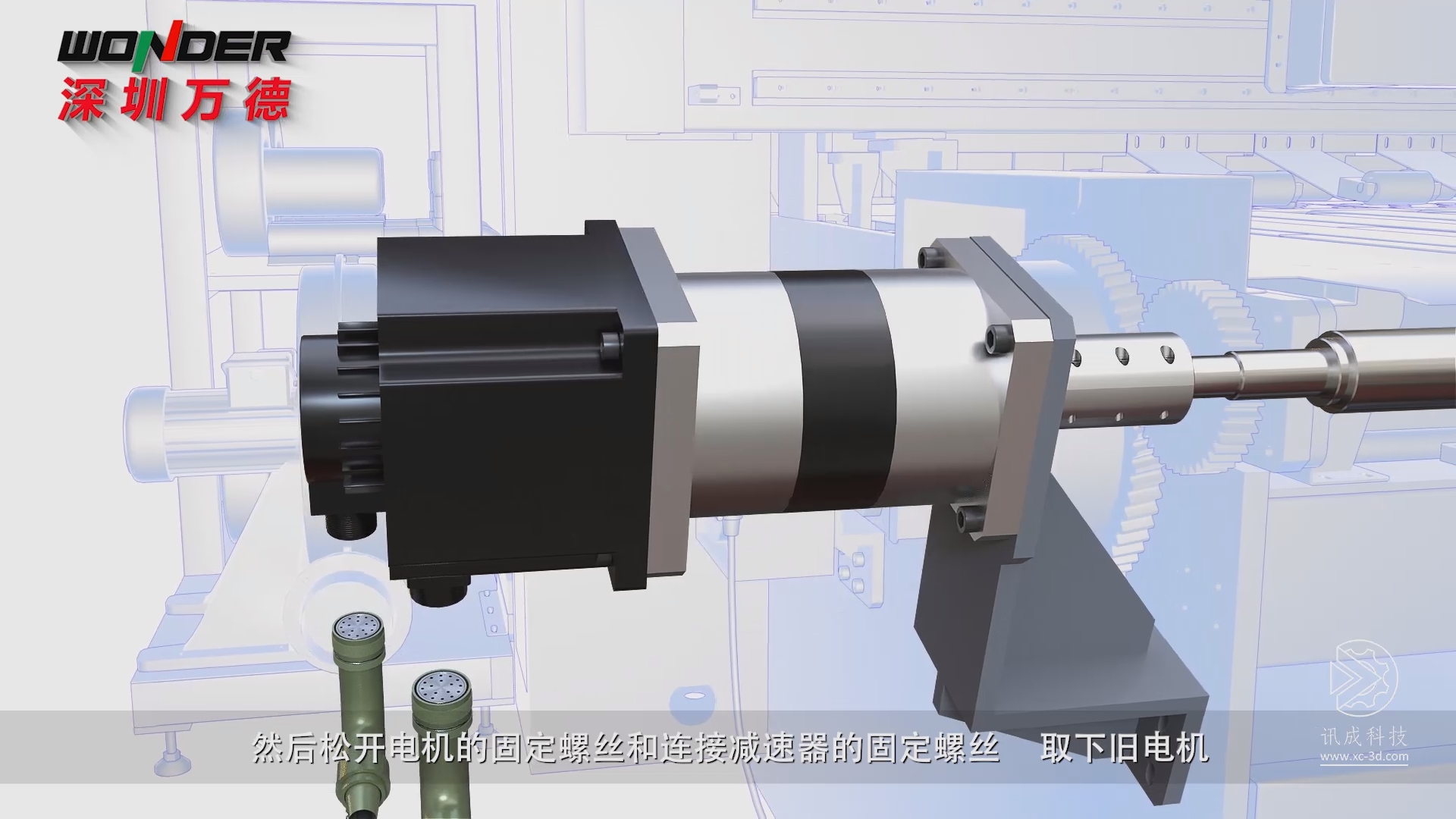

Precise disassembly and assembly guidance significantly improve maintenance efficiency. The digital printing machine repair animation by Shenzhen Wander Digital Technology displays the sequence of part disassembly and assembly with exploded views, marking key points and precautions. Maintenance personnel report that using animated guidance reduces average repair time by 35% and lowers rework rates by 50%. Especially in the maintenance of precision equipment, the intuitive presentation of critical parameters like tolerance matching and installation torque in animations effectively prevents secondary damage caused by improper operation.

Standardized Training: Accelerating Technology Skill Inheritance

Rapid onboarding of new employees is the core value of 3D animation training. Foshan Jinbing Machinery's multilingual 3D training animations systematically cover the entire process of equipment operation, maintenance, and repair. New after-sales service engineers can master the maintenance skills for core equipment within 3 weeks through animated learning, shortening the training period by 50% compared to traditional apprenticeship models. Simultaneously, training quality is standardized, avoiding capability gaps due to mentor differences.

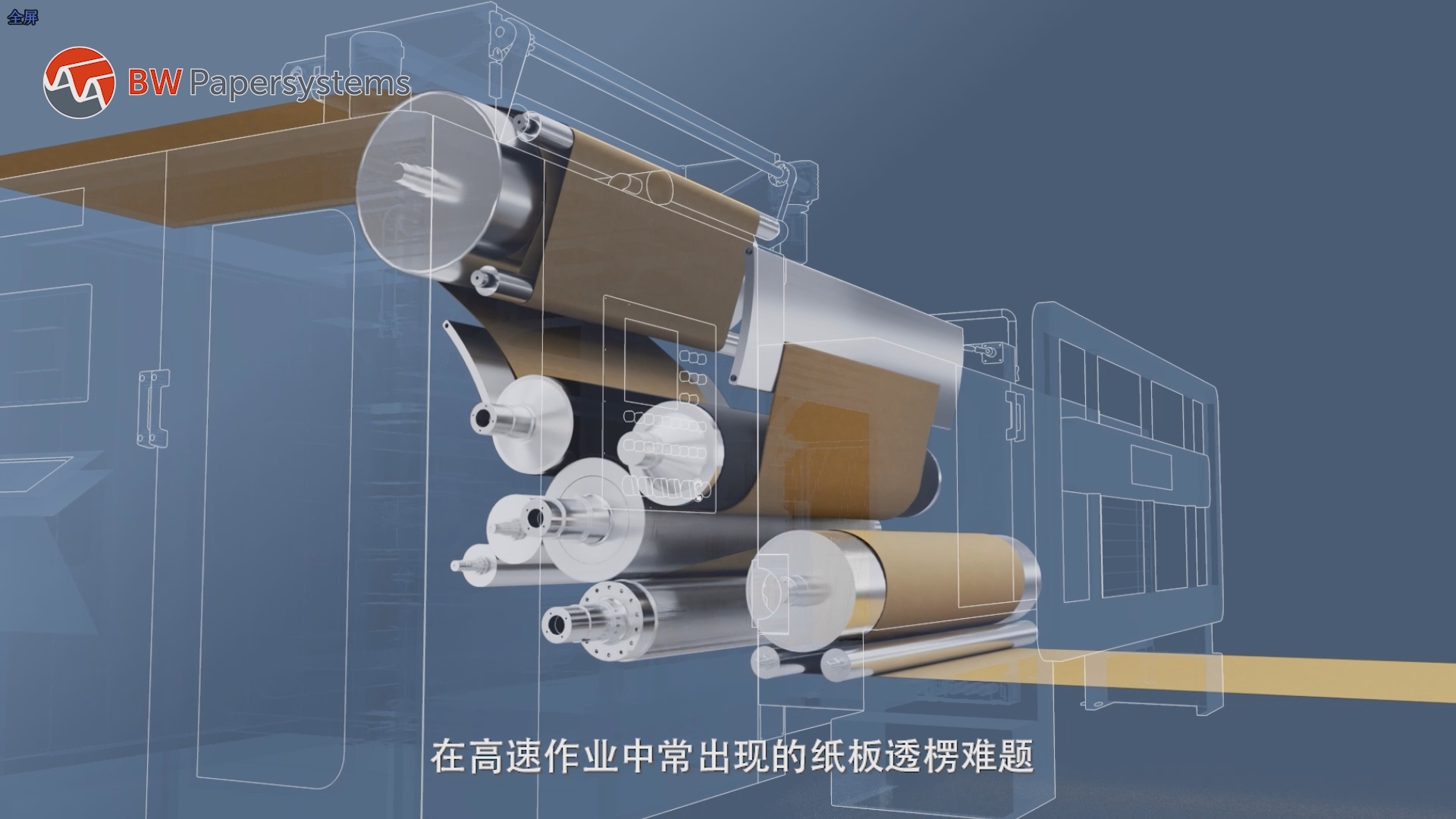

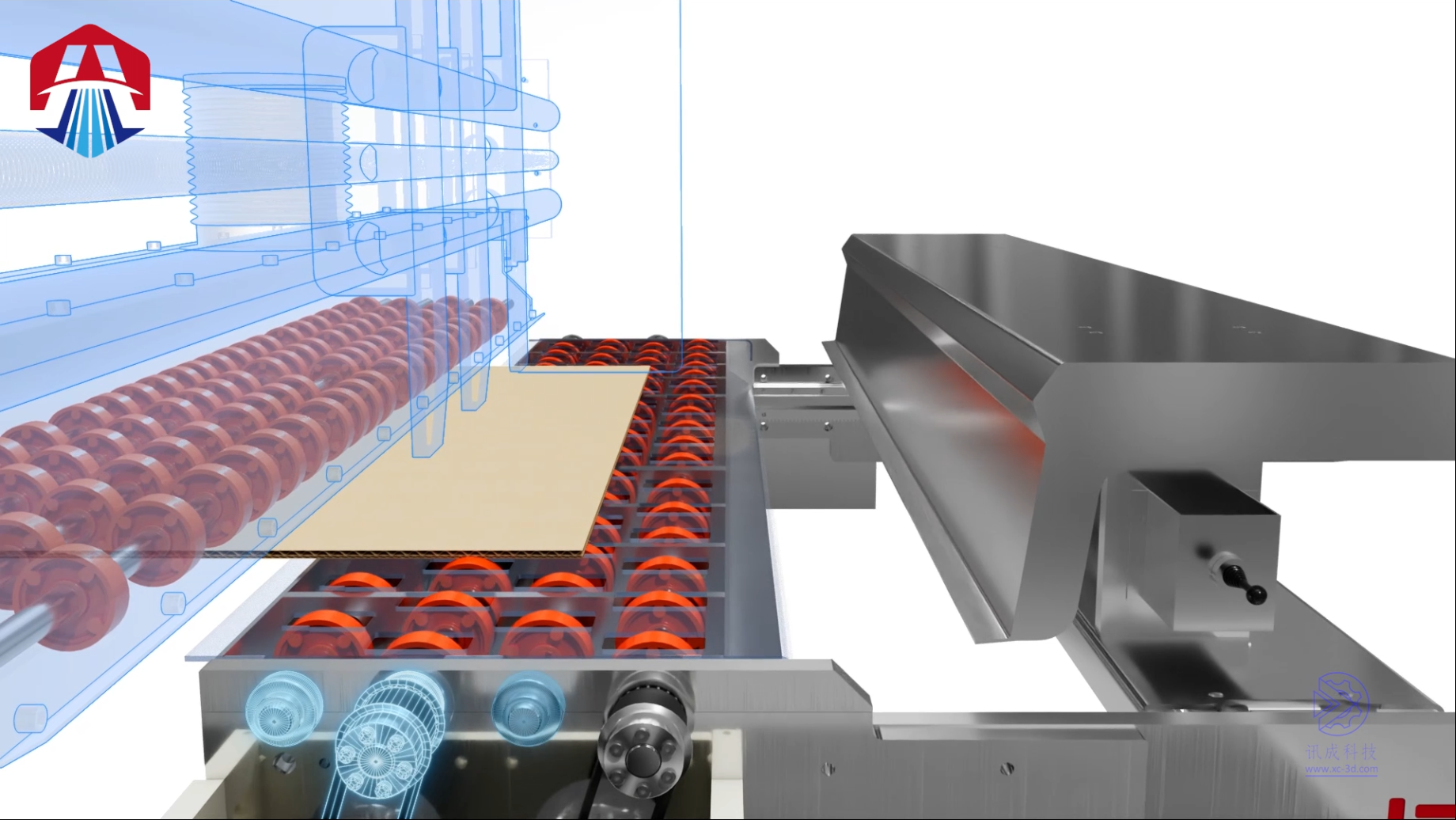

Visualization of complex processes deepens technical understanding. America's Marquip BW Papersystems' corrugator roll maintenance animation demonstrates key maintenance points of core components through techniques like slow motion and local perspectives. This deep visualization enables maintenance personnel to not only know 'how to do' but also understand 'why it's done this way,' allowing them to respond flexibly to unexpected situations. After implementing this animated training, the unexpected equipment failure rate for the company's clients decreased by 30%.

Preventive Maintenance: Reducing Failures at the Source

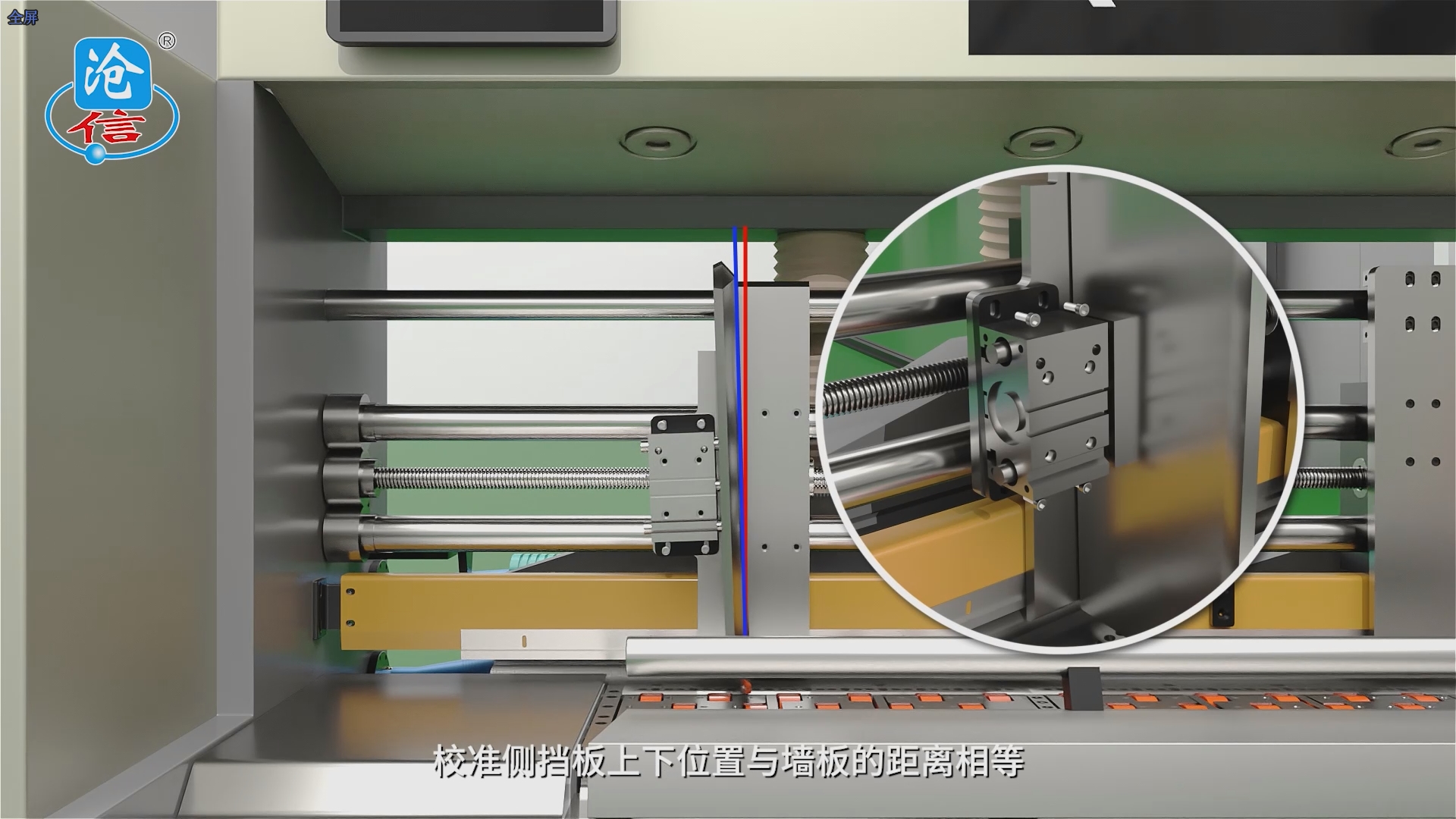

Standardization of maintenance procedures avoids oversight. Xiamen Sanlei Packaging Materials' flexographic printing press maintenance animation clearly indicates the location of each maintenance point, maintenance cycle, and operational standards. Customers who follow the animated guidance to establish preventive maintenance plans have seen the execution rate of regular equipment maintenance increase from 65% to 90%, effectively extending equipment lifespan and reducing losses from unexpected downtime.

Optimization of wear-part management reduces spare parts inventory costs. Ruichang Carton Machinery's 3D training animations clearly show the location of wear parts, replacement standards, and warning indicators. Customers can formulate precise spare parts procurement plans based on animated guidance, avoiding downtime due to shortages and reducing capital tied up in excess inventory. According to customer feedback, after implementing this solution, spare parts inventory costs were reduced by 25%, and equipment availability increased by 15%.

Knowledge Management: Building Enterprise Technical Assets

Digitalization of technical experience enables efficient knowledge transfer. Dongguan Xusen Intelligent Technology's electromagnetic temperature control system maintenance animations convert the repair experience of senior engineers into standardized 3D content. This knowledge accumulation mechanism ensures that the company's core technologies do not rely on individual experts but form reproducible and inheritable organizational assets. When senior engineers retire or transfer, their experience is preserved and benefits the entire team.

Multilingual support enhances global service capabilities. Fujian Fangguangshengshi's IGV intelligent forklift animations are available in multiple language versions, effectively overcoming language barriers in overseas services. Technical service personnel can communicate effectively with clients through the visual language of animations, even without a common spoken language. This initiative has reduced the company's international service response time by 40% and significantly improved customer satisfaction.

Data-Driven: Continuously Optimizing the Service System

Service data analysis guides product improvement. By collecting animation usage data, companies can identify common equipment failure points and customer focus areas. Shanghai Yituo Papermaking Machinery analyzed installation animation viewing data and found that customers repeatedly watched the foundation preparation section. They then optimized the installation guidance process and improved product design to reduce installation complexity at the source.

Insights into customer behavior optimize service resource allocation. This data-driven service planning reduces service response time by 30% while also cutting travel costs by 15%.

Return on Investment: Quantifying Cost Reduction and Efficiency Improvement Results

Cost structure optimization shows significant results. Based on practice data from multiple manufacturing enterprises, after introducing 3D animation after-sales service solutions, average service costs have decreased by 30%-40%, primarily reflected in reduced travel expenses, improved service efficiency, and lower rework rates.

Increased customer satisfaction brings sustained value. Customer feedback from Guangdong Hengli Intelligent Equipment shows that satisfaction with problem resolution increased from 75% to 92% after using animated guidance. High-quality after-sales service not only enhances customer loyalty but also leads to a 25% increase in repeat purchase rates.

Talent training efficiency has greatly improved. Under traditional models, training a qualified after-sales service engineer takes 6-12 months, whereas through the 3D animation training system, this period can be shortened to 3-6 months, reducing talent training costs by over 40%.

3D industrial animation is reshaping every aspect of after-sales service in manufacturing, from cost control to efficiency improvement, from technology inheritance to customer experience. Its value has been validated through practices in numerous enterprises. For manufacturing companies pursuing excellent service, embracing this technological change is no longer an option, but a necessity.

Featured FAQs:

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in video format (e.g., the feeding unit of a printing press primarily explains how to adjust baffles and guides, and how to load paper; the printing unit explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machine manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The control always remains with the machine manufacturer.

Q: How to create 3D animations for equipment maintenance?

A: Most machinery and manufacturing plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animations can effectively solve this problem.

1. It is recommended to first create animations for common equipment failure points (including mechanical and electrical);

2. Record and document on-site maintenance to accumulate material for animation production;

3. Quantity: For large equipment, it is recommended to produce about 10-15 mechanical repair animations and 5-8 electrical repair animations initially; for medium and small equipment, about 6-8 mechanical repair animations and 3-5 electrical repair animations;

4. Equipment maintenance animation is a process of continuous accumulation and optimization with a relatively long production cycle. Project liaison personnel should be relatively stable.

Q: Which equipment is suitable for creating operation and maintenance animations?

A: Almost all equipment is suitable for creating operation and maintenance animations, from large single units costing millions to small ones costing tens of thousands or even a few thousand yuan.

Creating operation and maintenance animations not only solves after-sales service issues but also adds value to the company's brand and products, better promotes sales, and enhances customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services, covering everything from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in astonishing 3D animations. This not only brings a unique visual experience to clients but also quickly resonates with them.