In the field of industrial maintenance, cost control has always been a key focus for enterprises. Traditional maintenance methods have problems such as high training costs, low maintenance efficiency, and resource waste. The introduction of 3D animation technology has brought new solutions for industrial maintenance cost optimization.

3D Animation Helps Reduce Maintenance Training Costs

Traditional industrial maintenance training usually relies on physical equipment and on-site guidance, which not only requires significant investment in equipment resources but also professional trainers for long-term instruction. 3D animation can create highly realistic virtual maintenance scenarios, presenting complex repair processes in an intuitive way. Trainees can repeatedly learn from the animation, free from time and space constraints. Ruichang Carton Machinery Manufacturing Co., Ltd. is a specialized carton machinery manufacturer integrating R&D, production, sales, and service. After introducing 3D animation produced by Xiamen Xuncheng for training, the training time for new employees was shortened from one month to two weeks, and training costs were reduced by 30%. This is because 3D animation can simulate various fault scenarios, allowing trainees to practice repeatedly in a virtual environment, improving training effectiveness and reducing the wear and tear of actual equipment and training time.

3D Animation Improves Maintenance Efficiency and Reduces Downtime

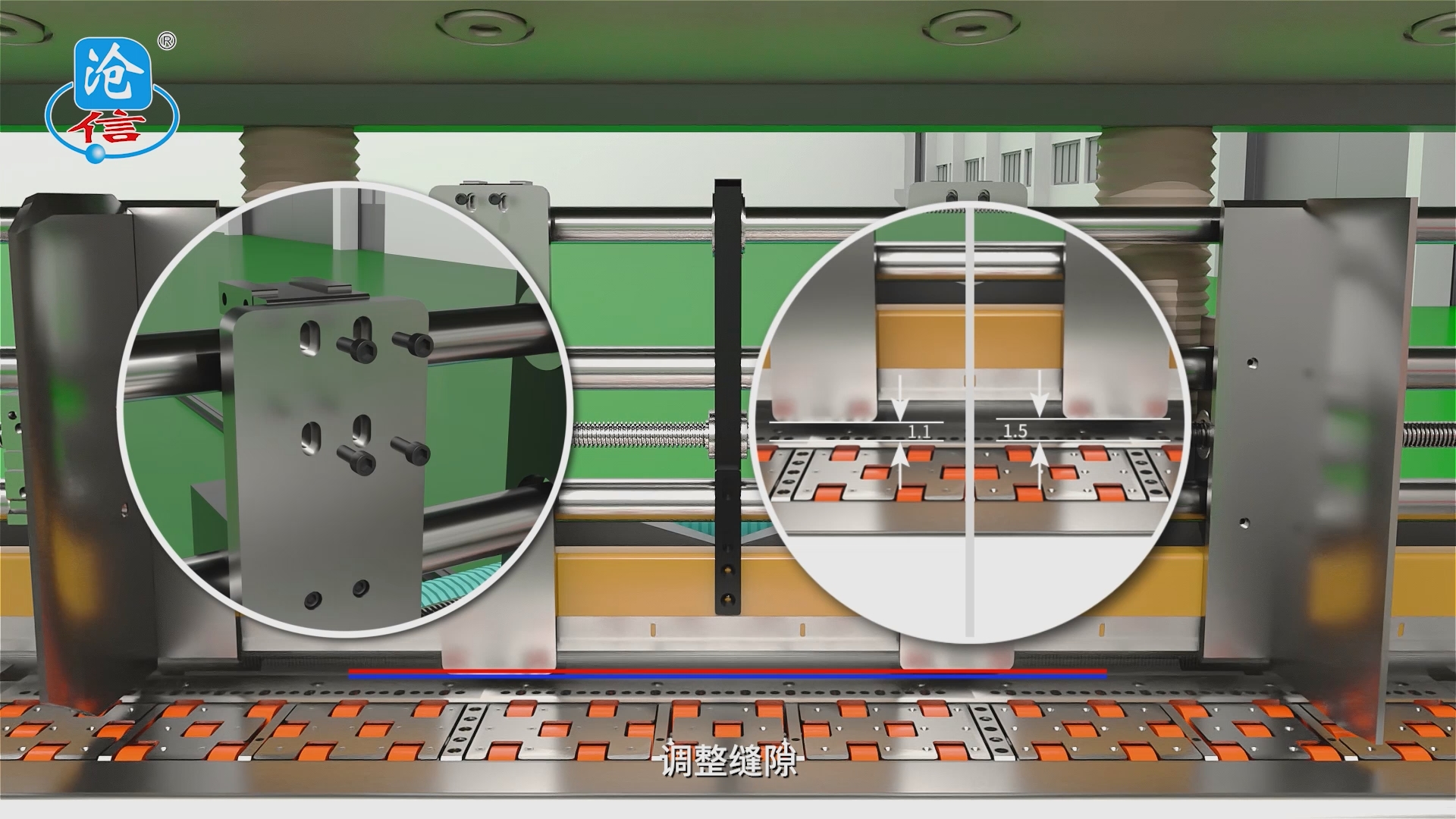

In industrial production, downtime caused by equipment failure brings huge economic losses to enterprises. 3D animation can quickly provide detailed maintenance guidance when a fault occurs. Maintenance personnel can quickly understand the fault location, repair steps, and required tools through the animation, thus shortening the repair time. Ruichang Jinggong's after-sales service personnel provide maintenance animation to customer factories. By repeatedly learning from the 3D animation, customers can also identify potential problems in advance, greatly reducing downtime losses and further improving equipment reliability and production efficiency.

From Experience Dependency to Standardized Execution

3D animation supports dynamic simulation and optimization of maintenance processes. Newly hired maintenance personnel often lack practical operational experience, and traditional training methods require experienced technicians to spend a lot of time and effort on on-site guidance. Maintenance animation provides an efficient and convenient way for after-sales personnel training. New employees can quickly understand the equipment structure, maintenance procedures, and key process points by watching the animation, shortening the training cycle. This standardized design makes maintenance processes replicable and traceable, promoting refined equipment management.

In summary, the application of 3D animation in the field of industrial maintenance has achieved effective cost optimization through reduced training costs, improved maintenance efficiency, and standardized execution. With the continuous development of technology, the application prospects of 3D animation in industrial maintenance will become even broader.

Featured FAQs:

Q: How to produce 3D animation related to equipment maintenance?

A: Most machinery and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animation can effectively solve this problem.

1- It is recommended to first produce animation for common equipment fault points (including mechanical and electrical);

2- Record and document on-site maintenance to accumulate material for animation production;

3- Quantity: It is recommended to produce about 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment in the early stage; about 6-8 mechanical maintenance animations and 3-5 electrical maintenance animations for medium and small equipment;

4- Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project contact personnel should be relatively stable.

Q: Will equipment usage animation expose sensitive structures of the equipment?

A: No.

Equipment usage animation demonstrates the content of traditional paper operation manuals in the form of animated videos (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles, guides, and how to feed paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Machinery manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always remains with the machinery manufacturer.

Q: Is equipment usage animation very expensive?

A: First, the conclusion: Equipment usage animation creates benefits for machinery manufacturers. The greater the investment, the greater the return.

The cost of producing equipment usage animation generally ranges from tens of thousands to hundreds of thousands of yuan, or even higher. While it may seem expensive on the surface, the average cost per piece of equipment is not high.

How does equipment usage animation create benefits for machinery manufacturers?

1- Low averaged cost. Machinery equipment generally undergoes minor modifications every 2 years and major modifications every 4 years. The total cost of producing animation videos is very low when averaged across each machine;

2- Equipment premium. According to actual measurement data from machinery manufacturers, for every yuan invested in producing equipment operation and maintenance animation, the equipment sales premium generated is about 3-5 yuan, i.e., 3-5 times);

3- Significantly reduce after-sales service costs, especially during the equipment warranty period;

4- Effectively improve customer stickiness;

5- More competitive compared to similar products.

Characteristic: Large initial investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startup teams, overseas clients, listed companies, and foreign-funded enterprises. Specializing in providing 3D animation creation for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. Offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in astonishing 3D animation. This not only brings a unique visual experience to clients but also quickly wins their hearts.