In industrial production, the continuous and stable operation of equipment is the cornerstone of normal enterprise production. Wearable parts, as components that are easily worn out and require regular replacement, directly affect equipment operational efficiency and lifespan. Wearable parts replacement animation, as an emerging visual measure, is gradually becoming an important means to ensure continuous equipment operation.

Clearly Presenting Wearable Part Location and Structure

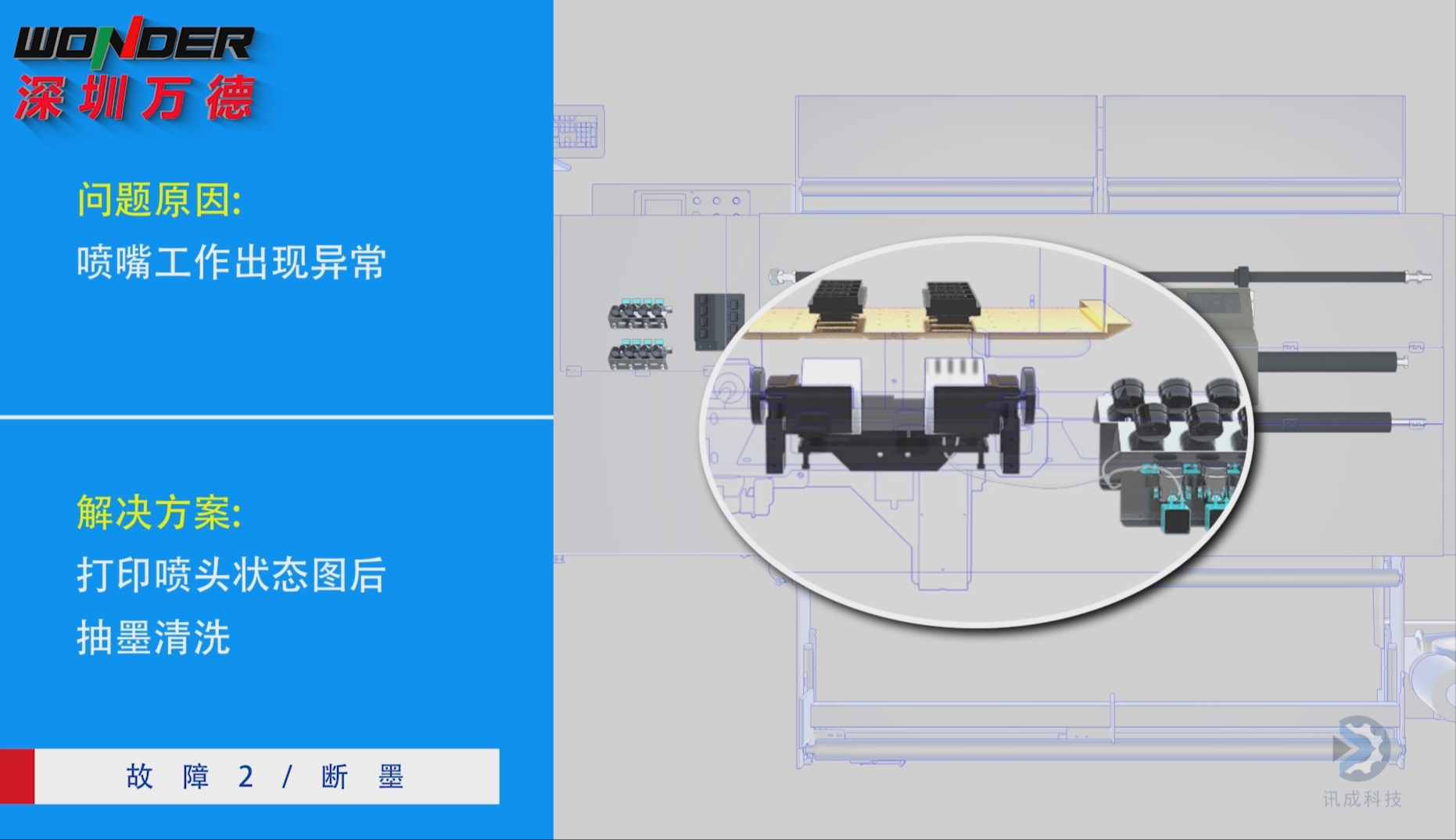

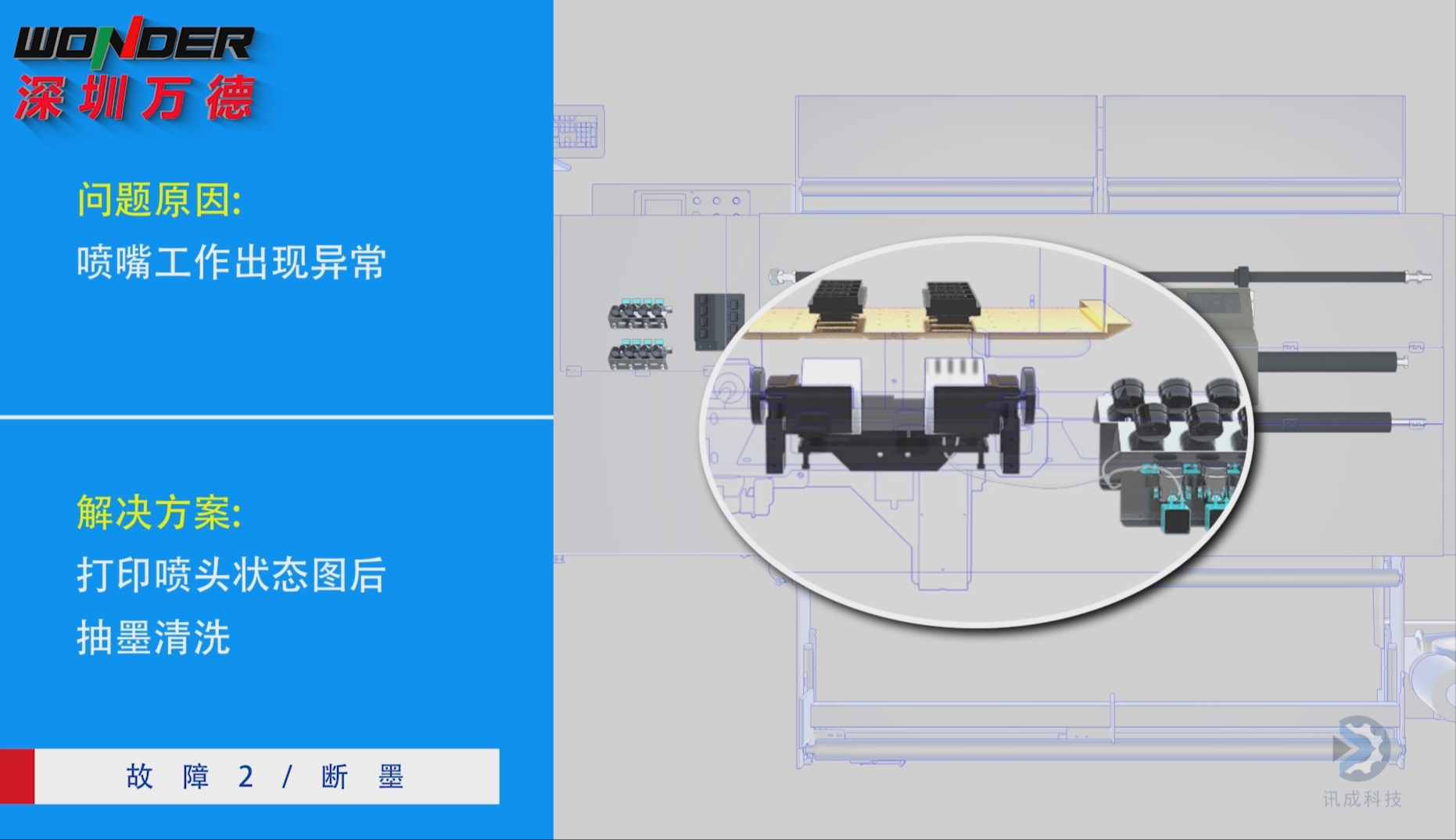

Traditional equipment maintenance manuals often present information about wearable parts in text and 2D diagrams, which can be difficult for operators unfamiliar with the equipment structure to understand. Wearable parts replacement animation, through 3D modeling technology, can accurately restore the appearance and internal structure of the equipment, clearly displaying the specific location and structural characteristics of wearable parts within the equipment. For example, Shenzhen Wande Digital Technology Co., Ltd. commissioned Xiamen Xuncheng to produce wearable parts replacement animations for its series of digital printing machines, covering core processes such as ink path system maintenance, common fault diagnosis, printhead replacement, and mechanical wearable part replacement.

Dynamically Demonstrating Replacement Procedures and Steps

Wearable parts replacement animation can dynamically demonstrate the entire replacement process and each step, with every stage presented in a vivid animated form. The fault diagnosis animation produced by Xiamen Xuncheng for Wande Digital's digital printing equipment simulates common fault scenarios such as abnormal nozzle operation, ink suction abnormalities, and poor color print quality. Technicians can learn by watching, observe the disassembly process of faulty parts, and master troubleshooting methods and repair techniques. On-site operators can follow the animation's demonstration to perform the replacement step by step, avoiding errors and rework caused by unfamiliarity with the replacement procedure.

Emphasizing Operational Specifications and Precision Requirements

Different wearable part replacements have different requirements for operational specifications and precision. Animation can emphasize operational specifications and precision requirements through close-up shots, dimension annotations, and other methods. In the wearable parts replacement animation, Xiamen Xuncheng uses methods such as rotating, perspectivizing, and scaling the model to show the disassembly and assembly sequence of the entire set of components and tool usage methods, along with voice narration and text prompts, to ensure the standardization of the entire replacement process and improve equipment reliability and stability.

Providing Flexible Training Methods

Wande Digital has not only produced animations for equipment operation, maintenance, repair, wearable parts replacement, equipment safety, and equipment assembly, but also stored these animated videos on electronic devices for operators to learn at their own time and convenience. Whether on-site, in a training room, or at home, as long as an electronic device is available, one can watch the animation to learn. This flexible learning method breaks through time and space constraints, improves work efficiency, and enhances the timeliness of equipment maintenance.

Wearable parts replacement animation, with its intuitive display advantages, emphasis on equipment safety and accuracy, and ease of training, has become a visual measure for ensuring continuous equipment operation. With the continuous development of industrial technology, wearable parts replacement animation will play an even more important role in the field of industrial equipment maintenance, providing strong support for enterprises' safe production and efficient operation.

Selected FAQs:

Q: Will equipment use animations expose sensitive equipment structures?

A: No.

Equipment use animations are demonstrations of traditional paper operation manual content in the form of animated videos (e.g., the paper feeding unit in a printing machine mainly explains how to adjust the baffle and guide, and how to load paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Mechanical factories can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always rests with the mechanical factory.

Q: Are equipment use animations very expensive?

A: To conclude first: Equipment use animations create benefits for mechanical factories. The greater the investment, the greater the return.

The production cost of equipment use animations generally ranges from tens of thousands to over a hundred thousand, or even higher. While seemingly expensive on the surface, the actual average cost per machine is not high.

How do equipment use animations create benefits for mechanical factories?

1-Low amortization cost. Machines are generally updated slightly every 2 years and significantly every 4 years. The total cost of animation video production amortized per machine is very low.

2-Equipment premium. According to actual test data from mechanical factories, for every 1 yuan invested in producing equipment operation and maintenance animations, the sales premium generated for the equipment is about 3-5 yuan (i.e., 3-5 times).

3-Significant reduction in after-sales service costs, especially during the equipment warranty period.

4-Effective improvement of customer loyalty.

5-More competitive compared to similar products.

Characteristics: Large initial investment, small subsequent investment.

Q: How can small companies without a supporting team produce 3D animations?

A: Many client companies are not large and are mostly located in other provinces. Xuncheng provides flexible and high-quality animation video production solutions:

1-Xuncheng's core team has many years of manufacturing experience and can effectively communicate with clients.

2-If clients do not have 3D models of their products, Xuncheng can provide professional modeling services.

3-Assisting clients in optimizing video scripts.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startups, overseas customers, listed companies, to foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at an exhibition, visiting clients, expanding into overseas markets, or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animations. This not only provides clients with a unique visual experience but also quickly captivates them.