In the full life cycle management of industrial equipment, the quality of the maintenance stage directly affects the operational efficiency and lifespan of the equipment. Traditional maintenance manuals rely on textual descriptions and static images, leading to issues such as deviations in understanding operating procedures and insufficient communication of technical key points. Equipment maintenance animation uses 3D visualization technology to transform complex maintenance processes into dynamic images, providing operators with intuitive and precise technical guidance, thus becoming a digital solution for extending equipment service life.

I. Technical Characteristics and Adaptability to Equipment Maintenance Needs

(I) High-Precision Modeling and Component-Level Restoration

In equipment maintenance, traditional manuals or 2D drawings struggle to clearly display disassembly steps, component positions, and operating procedures for complex mechanical structures. 3D industrial animation, through 3D modeling and dynamic demonstrations, can intuitively present internal equipment structures, maintenance paths, and key precautions. For example, Shenzhen Wande Digital Technology Co., Ltd. commissioned Xiamen Xuncheng to produce wear part replacement animations for its series of digital printing machines, covering core processes such as ink path system maintenance, common fault diagnosis, printhead replacement, and mechanical wear part replacement. With the cooperation of animation visuals, voiceovers, and text prompts, the entire component replacement process becomes more intuitive and understandable.

(II) Dynamic Process Simulation and Risk Warning

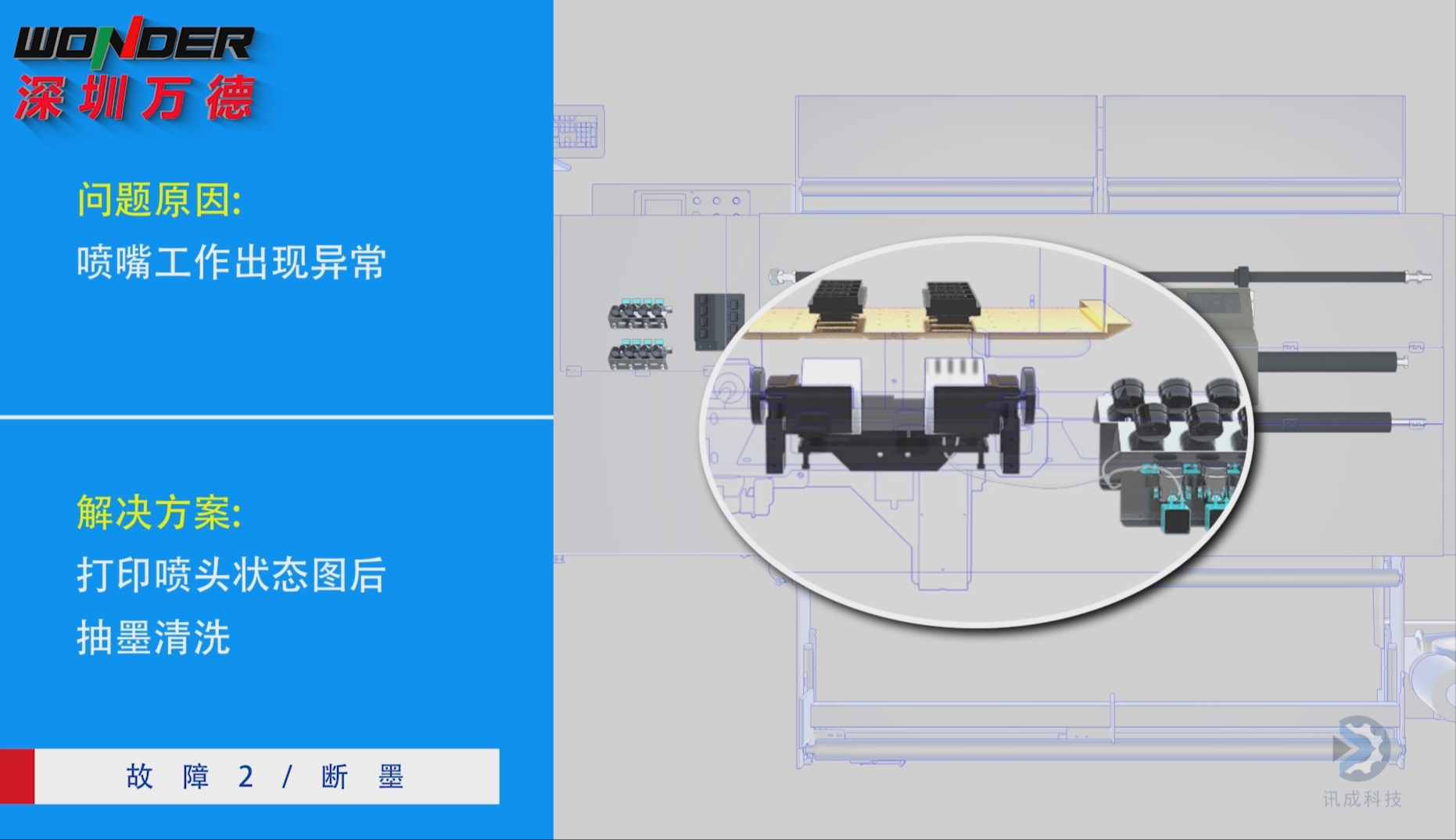

For sudden equipment failures, 3D industrial animation can simulate fault phenomena, causes, and troubleshooting steps, helping technicians quickly identify problems and develop solutions. The fault diagnosis animations produced by Xiamen Xuncheng for digital printing equipment simulate common fault scenarios such as abnormal nozzle operation, abnormal ink extraction, and poor color printing effects. Technicians can learn by watching, observe the disassembly process of faulty components, and acquire troubleshooting methods and repair techniques.

II. Core Application Scenarios and Implementation Value

(I) Standardized Training: Visualized Operating Guide

The animated videos produced by Xiamen Xuncheng not only allow new employees to watch repeatedly and understand key installation points and precautions, but also enable after-sales service engineers to guide production personnel in achieving standardized training. This allows customer employees to prepare in advance, shorten training cycles, and improve their operational skills and safety awareness.

(II) On-Site Guidance: Dynamic Operation Manual

At the site of complex electromechanical system maintenance, 3D animation becomes the technician's "digital mentor." Xiamen Xuncheng produced 3D animated videos for digital printing machines, demonstrating the production processes of the entire equipment, including operation, maintenance, repair, wear part replacement, and safety. It not only replicates the equipment operation and maintenance procedures but also breaks down the location of wear parts and the replacement process into standardized steps through dynamic demonstrations. Equipment repair animations can clearly show the disassembly of the equipment, replacement of components, and reassembly, with every step clearly visible.

(III) Preventive Maintenance: Boosting Equipment Maintenance Efficiency

Equipment maintenance typically involves multiple stages and steps, and equipment maintenance animations can provide detailed and intuitive demonstrations of the repair process. In the digital printing machine equipment repair animations produced by Xiamen Xuncheng, the sequence of disassembling various components is accurately shown, helping to prevent maintenance personnel from damaging other parts due to improper operation. By watching the animations, maintenance personnel can familiarize themselves with the process in advance, develop scientific maintenance plans, and thus improve maintenance efficiency.

Equipment maintenance animation reconstructs the technical ecosystem of equipment maintenance by integrating technical visualization with engineering simulation. Its high-precision modeling, dynamic simulation, and AR interaction capabilities make animations a core link connecting maintenance standards, operational execution, and quality acceptance. With the deepening application of digital twin and industrial metaverse technologies in the future, maintenance animations will play an even more critical role in the equipment maintenance cycle, assisting industries in achieving cost reduction, efficiency improvement, and intelligent upgrades.

Selected FAQs:

Q: Will operation and maintenance animations expose sensitive equipment structures?

A: No.

Operation and maintenance animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to feed paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Mechanical factories can also delete or deform sensitive equipment structures when providing equipment models. The control always remains with the mechanical factory.

Q: How can small companies without an "Equipment Operation Manual" produce operation and maintenance animations?

A: Xuncheng can provide a full-chain service for equipment operation and maintenance animation production. Specifically:

1. After the equipment is installed and debugged, the mechanical factory can record the on-site training with multiple fixed cameras and convert it into documents (Xuncheng can also provide this service); 2. Xuncheng will categorize and optimize the relevant content; 3. The documents will be sent to the mechanical factory for confirmation; 4. Animations will be produced.

Q: Which equipment is suitable for producing operation and maintenance animations?

A: Almost all equipment is suitable for producing operation and maintenance animations, from large single machines costing millions to small equipment costing tens of thousands or even thousands of yuan.

Producing equipment operation and maintenance animations solves after-sales service issues on one hand, and on the other hand, it adds value to the company's brand and products, better promotes sales, and increases customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, clients span various types of enterprises including startup teams, overseas clients, listed companies, and foreign-invested enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibitions or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented through stunning 3D animations. This not only brings unique visual experiences to clients but also resonates deeply with them.